Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

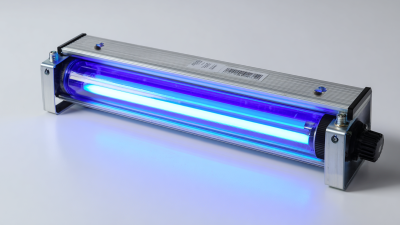

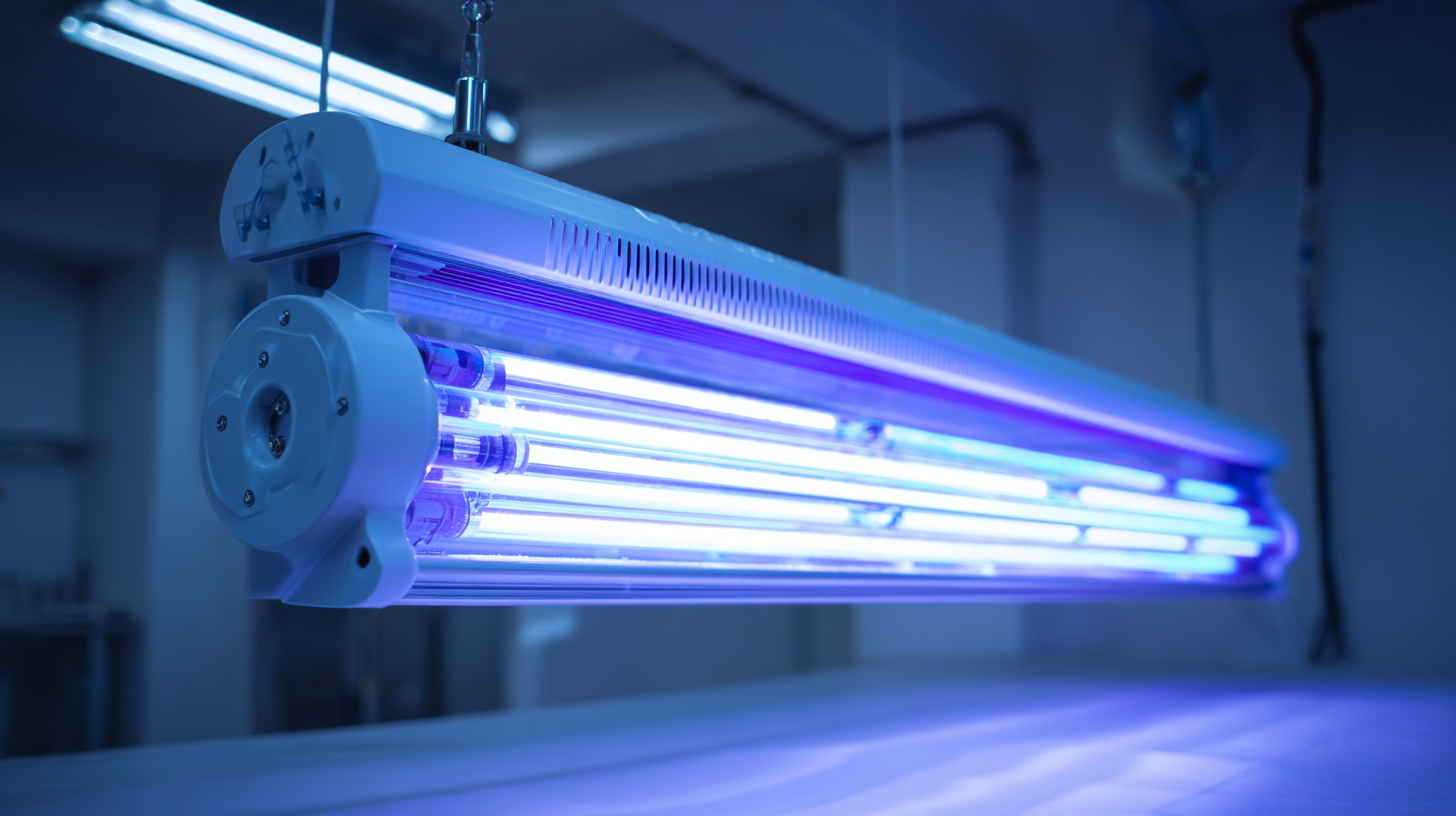

In recent years, the utilization of UV LED light lamps has revolutionized various industries, particularly in the realm of curing technologies. These innovative devices harness the power of ultraviolet light to expedite the curing process of inks, coatings, adhesives, and other materials, delivering enhanced productivity and efficiency. Unlike traditional curing methods, UV LED light lamps offer numerous advantages, including lower energy consumption, reduced heat generation, and a more environmentally friendly operation. As businesses strive to optimize their production processes and meet the ever-increasing demands for speed and quality, the integration of UV LED light lamps has emerged as a pivotal solution. This exploration delves into the impact of UV LED light lamps on modern curing technologies and highlights how their adoption can significantly boost productivity, offering a competitive edge in today's fast-paced market.

The evolution of UV LED light technology has significantly transformed curing applications across various industries. Initially, traditional UV lamp technologies relied on mercury vapor and emitted considerable heat, leading to inefficiencies and environmental concerns. However, advancements in UV LED technology have enabled a shift towards more energy-efficient, compact, and flexible curing solutions. This evolution has allowed manufacturers to meet strict regulatory standards while reducing operational costs.

Moreover, the precise wavelength output of UV LEDs enhances the curing process by ensuring a more targeted interaction with photosensitive materials. This not only speeds up curing times but also improves the consistency and quality of the final product. Industries such as printing, coatings, and adhesives have embraced this innovation, resulting in increased throughput and enhanced productivity. As UV LED technology continues to evolve, its applications are expected to expand, driving further improvements in efficiency and sustainability across various sectors.

| Parameter | Conventional UV Lamp | UV LED Light Lamp | Benefits of UV LED |

|---|---|---|---|

| Curing Speed | 10-20 seconds | 5-10 seconds | Faster throughput |

| Energy Consumption | High | Low | Cost-effective |

| Lifespan | 1,000 hours | 20,000-30,000 hours | Reduced replacement costs |

| Heat Emission | High | Minimal | Less risk of distortion |

| Environmental Impact | Mercury content | No harmful materials | Sustainable solution |

| Initial Investment | Lower | Higher | Long-term savings |

The advent of UV LED light lamps has revolutionized curing technologies, presenting several key advantages over traditional curing methods. One significant benefit is the reduced energy consumption. According to a report by the U.S. Department of Energy, UV LED systems can consume up to 70% less energy than conventional mercury vapor lamps, making them an attractive option for manufacturers seeking to lower operating costs while enhancing productivity. The efficiency of UV LED lamps not only boosts economic performance but also supports sustainability efforts in the industry.

Another advantage lies in their operational longevity and performance consistency. Research indicates that UV LED lamps have an impressive lifespan of up to 20,000 hours compared to only 1,000 hours for traditional curing lamps. This longevity translates to less frequent replacements and decreased downtime, further increasing productivity. Additionally, UV LED light provides more precise control over the curing process, allowing for faster curing times and improved product quality. A study published in the Journal of Industrial Technology observed that UV LED curing can reduce processing times by as much as 50%, significantly enhancing production workflows in various sectors, including printing and coatings.

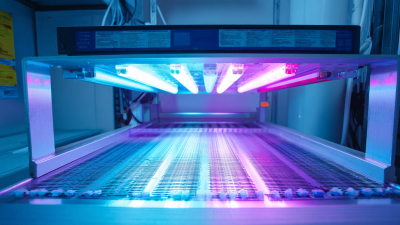

The rapid advancement of UV LED curing technologies is revolutionizing production processes across various industries. With the global UV curing system market projected to grow from $6.7 billion in 2024 to $8.96 billion by 2033 at an annual growth rate of 4.4%, the impact of these technologies cannot be understated. UV LED curing systems enhance product quality and production speed significantly. Unlike traditional curing methods, which are often energy-intensive and time-consuming, UV LED systems provide instant curing, leading to faster production cycles and reduced operational costs.

The effects on product quality are equally compelling. UV LED curing delivers consistent and thorough curing, resulting in superior adhesion, reduced defects, and enhanced durability. This guarantees a higher standard of finished products that meet stringent market demands. As manufacturers increasingly adopt UV LED technologies, the improved production speeds and enhanced product quality foster greater competitiveness in the market. The integration of these modern curing technologies marks a significant leap towards optimizing efficiency while maintaining high-quality output in manufacturing.

The application of UV LED light in modern curing technologies has spurred substantial advancements across various industries, particularly in coatings and 3D printing. In the coatings sector, the integration of graphene into protective and functional coatings has emerged as a game changer, leveraging graphene’s exceptional mechanical strength, thermal conductivity, and corrosion resistance. This innovation not only enhances product durability but also aligns with the growing demand for high-performance materials in commercial applications.

In the realm of 3D printing, the industrial market is anticipated to surpass $20 billion by 2023, driven by increased adoption in aerospace and healthcare sectors. The rapid advancements in UV curing processes are paving the way for faster production times and improved material properties. As the industry evolves, it increasingly relies on the efficiency of UV LED technology to produce intricate designs with high precision, ultimately resulting in significant productivity gains. This synergy between UV LED applications and modern manufacturing techniques highlights the transformative potential of these technologies in driving future growth within the coatings and 3D printing markets.

The future of UV LED curing technologies looks promising, driven by innovations that enhance productivity across various industries. According to a recent report by Smithers Pira, the UV LED market is projected to grow at a compound annual growth rate (CAGR) of 12.1% from 2021 to 2026. This growth is attributed to the acceleration of manufacturing processes and the increasing demand for eco-friendly solutions. UV LED curing systems offer faster curing times—often reducing production times by up to 50% compared to traditional curing methods—allowing companies to increase throughput and meet dynamic market demands.

Furthermore, advancements in UV LED technology are leading to higher energy efficiency levels, which significantly impact operational costs. Industry data indicates that UV LED systems consume up to 80% less energy than traditional mercury-based lamps. Additionally, the reduced heat output minimizes thermal damage to heat-sensitive substrates, enabling manufacturers to utilize a wider range of materials. As companies continue to adopt these technologies, the integration of UV LED systems is expected to redefine productivity benchmarks in the printing, aerospace, and automotive sectors, showcasing their vital role in the evolution of manufacturing processes.