Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

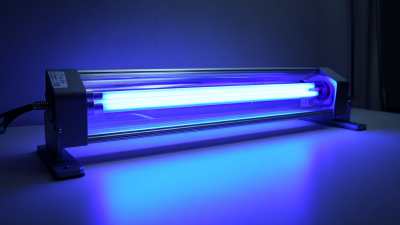

In recent years, UV LED curing lights have emerged as a transformative technology across various modern industries, notably in printing, automotive, and electronics. According to a report by Research and Markets, the global UV LED market is projected to reach $1.277 billion by 2027, growing at a CAGR of 30.1% from 2020. This rapid growth underscores the increasing adoption of UV LED curing lights, which offer numerous advantages over traditional curing systems, including energy efficiency, reduced heat emission, and improved durability of cured materials. The ability of UV LED curing lights to solidify inks and coatings instantaneously not only boosts productivity but also enhances environmental sustainability by reducing volatile organic compound (VOC) emissions. As industries seek innovative solutions that align with modern manufacturing demands, the significance of UV LED curing light in driving efficiency and sustainability cannot be overstated.

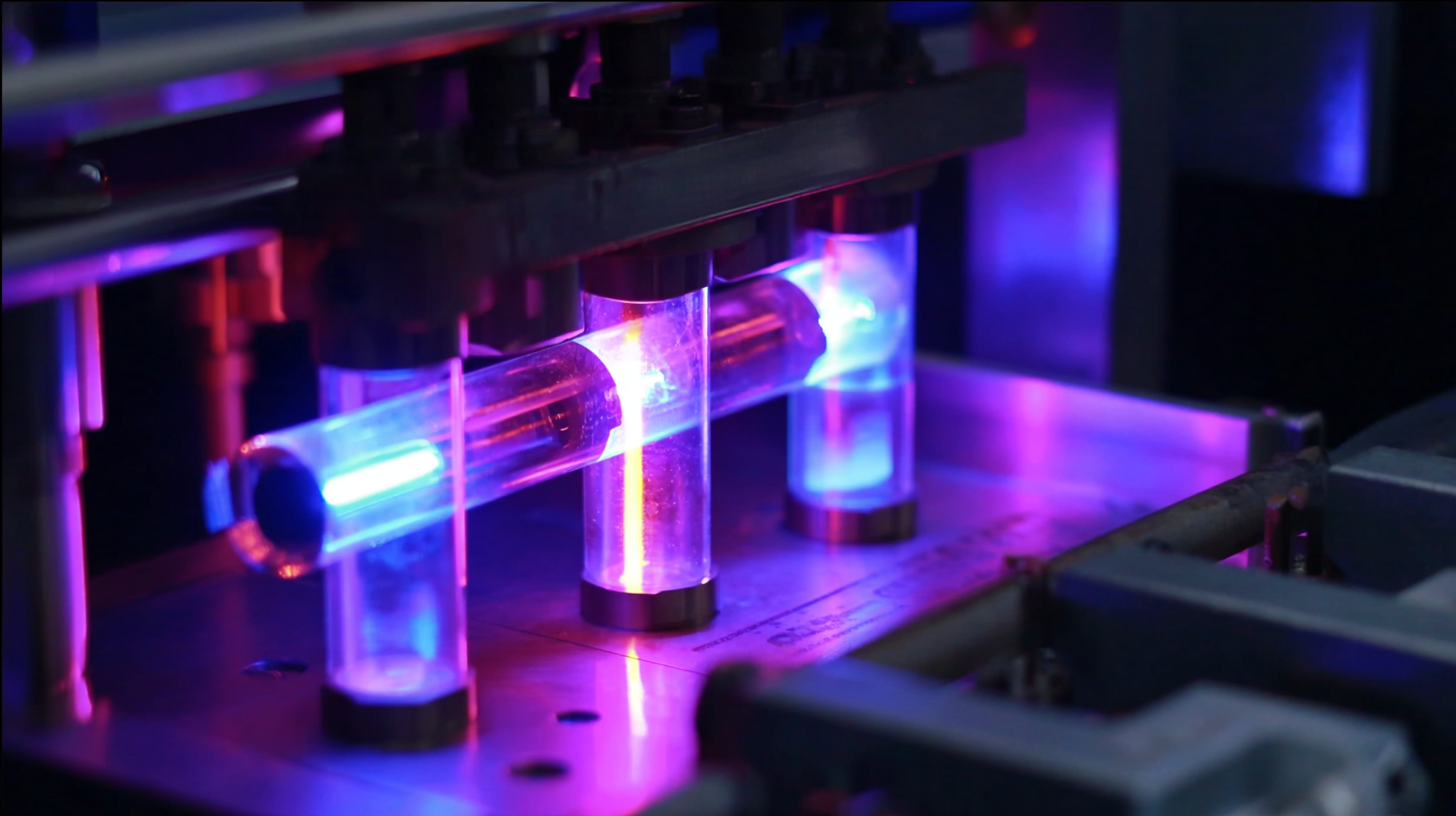

UV LED curing technology has emerged as a transformative solution across various modern industries. This sophisticated process involves the use of ultraviolet light to initiate polymerization, which allows materials, such as inks and coatings, to dry quickly and efficiently. According to a report by Smithers Pira, the global market for UV curing technology is projected to reach $5.3 billion by 2025, emphasizing its rapid adoption in sectors including packaging, graphics, and electronics.

One of the primary advantages of UV LED curing is its energy efficiency. Unlike traditional curing methods, UV LED systems consume significantly less power and produce less heat, which is crucial in protecting heat-sensitive substrates during manufacturing. Research by the Photopolymer Science and Technology group indicates that UV LEDs can achieve curing speeds up to 50% faster than conventional mercury lamps, resulting in higher productivity and reduced operational costs. These factors, combined with a longer lifespan of UV LED bulbs, position this technology as a sustainable alternative, further appealing to industries aiming for greener practices.

Moreover, the versatility of UV LED technology allows for advancements in a variety of applications, from automotive coatings to medical device manufacturing. A recent market forecast highlights that the demand for UV LED curing is expected to grow at a compound annual growth rate (CAGR) of 12.3% from 2020 to 2027. As industries seek faster, more efficient, and eco-friendly solutions, the role of UV LED curing technology will undoubtedly expand, creating new possibilities for innovation.

UV LED curing lights represent a significant advancement over traditional curing methods, offering numerous advantages that are transforming modern industries. One of the most notable benefits is energy efficiency. UV LED lights consume less power compared to conventional mercury vapor lamps, resulting in lower operational costs and a reduced carbon footprint. This energy efficiency not only saves money but also aligns with growing environmental sustainability initiatives, making UV LEDs an attractive option for businesses looking to enhance their green credentials.

Another critical advantage is the speed of curing. UV LEDs can cure materials in seconds, significantly increasing production rates and allowing for faster turnaround times. This rapid curing process minimizes bottlenecks in manufacturing, enabling companies to meet tight deadlines and respond swiftly to market demands. Furthermore, UV LEDs produce less heat during operation, which decreases the risk of damaging heat-sensitive substrates and expands the range of materials that can be effectively cured. These features highlight why industries are increasingly opting for UV LED technology to stay competitive and innovative.

The advent of UV LED curing technology has dramatically transformed various manufacturing sectors, particularly in printing, coatings, and electronics. According to a report by Smithers Pira, the UV LED curing market is projected to reach $3.8 billion by 2025, driven by the increasing demand for efficient and eco-friendly solutions. This technology offers significant advantages over traditional curing methods, including quicker curing times, reduced energy consumption, and lower environmental impact due to the elimination of volatile organic compounds (VOCs).

In the printing industry, UV LED curing facilitates high-quality finishes and swift processing times, enabling printers to meet the increasing demands for quicker turnaround and customization. A survey by Technavio indicates that the global UV printing market will grow at a CAGR of over 17% from 2021 to 2025, largely fueled by the adoption of UV LED systems. Meanwhile, in electronics manufacturing, UV LED curing plays a critical role in the fabrication of delicate components, where precise curing processes are fundamental to maintaining product integrity and performance. As industries continue to embrace sustainable practices, the versatility and efficiency of UV LED curing lights are set to redefine production standards across various fields.

UV LED curing technology is transforming the way various industries operate, enhancing efficiency and consistency in production processes. This innovation provides an almost instantaneous curing method, significantly reducing the time needed for products like labels and coatings to be ready for use. Reports indicate that UV LED curing systems can cut down drying times by up to 70%, ultimately increasing throughput and enabling businesses to meet high demands flexibly and efficiently.

To maximize efficiency with UV LED curing systems, businesses can follow several key tips. First, optimizing the distance from the UV source to the substrate can enhance energy absorption, improving curing depth and surface finish. Furthermore, maintaining the right balance between speed and intensity is crucial; too fast might lead to incomplete curing, while too slow can lead to unnecessary downtime. Regular maintenance of the curing equipment is essential to ensure consistent performance, as any degradation in lamp output can dramatically affect curing quality. As industries move towards more sustainable practices, leveraging insights from recent launches and technological advancements can lead to improved operational efficacy, directly impacting profitability.

| Industry | Application | Efficiency Gain (%) | UV LED Wavelength (nm) | Curing Speed (m/min) |

|---|---|---|---|---|

| Printing | Flexographic Printing | 30 | 365 | 20 |

| Automotive | Coating & Paint Curing | 40 | 395 | 15 |

| Cosmetics | Nail Gel Curing | 25 | 365 | 12 |

| Food Packaging | UV Coatings for Films | 35 | 365 | 25 |

| Electronics | PCB Coating | 50 | 405 | 10 |

The landscape of UV LED curing technology is continuously evolving, showcasing innovations that markedly enhance its applications across various industries. According to a report by Allied Market Research, the global UV LED market is projected to reach $6.43 billion by 2027, growing at a compound annual growth rate (CAGR) of 33.8% from 2020 to 2027. This rapid expansion is fueled by the growing demand for energy-efficient and environmentally friendly curing solutions in sectors such as printing, coatings, and adhesives.

One of the most significant trends is the integration of smart technology in UV LED curing systems. Advanced features such as IoT connectivity allow manufacturers to monitor and optimize curing processes in real time, enhancing efficiency and consistency. Additionally, the development of new formulations and materials specifically designed for UV curing is paving the way for even broader applications. For instance, the automotive industry is increasingly adopting UV LED curing for coatings that require high durability and quick turnaround times. These trends not only highlight the technological advancements within the industry but also point toward a future where UV LED curing becomes an integral part of sustainable manufacturing practices.