Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

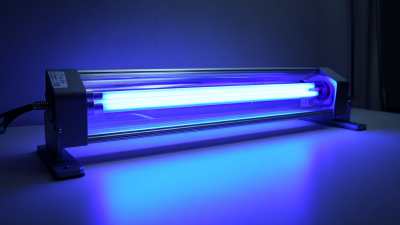

In recent years, the printing and coating industries have witnessed a significant transformation with the advent of UV LED curing technology. According to a report by Smithers, the global UV printing market is projected to grow to $7.2 billion by 2025, demonstrating an increasing demand for efficient and sustainable printing solutions. The implementation of UV LED curing equipment plays a crucial role in this evolution, offering remarkable benefits such as faster curing times, reduced energy consumption, and the ability to cure on a wider range of substrates.

The shift towards UV LED curing technology not only enhances productivity but also aligns with growing environmental regulations aimed at minimizing solvent emissions and waste. A study from the UV & EB Technology Consortium revealed that UV LED systems consume up to 60% less energy compared to traditional UV lamps, underscoring their efficiency and eco-friendly advantages. These factors are driving more companies to adopt UV LED curing equipment as a viable solution to meet market demands while maintaining sustainability goals. As we explore the top seven UV LED curing equipment options available today, it becomes clear that investing in this technology can significantly enhance printing and coating efficiency, positioning businesses for success in a competitive landscape.

As we approach 2025, UV LED curing technology is poised for significant advancements that will redefine its role in printing and coating processes. One prominent trend is the increasing energy efficiency of UV LED systems. Manufacturers are focusing on developing equipment that consumes less power while maintaining high output levels, making it more sustainable and cost-effective for users. This shift not only reduces operational expenses but also minimizes the environmental footprint of the curing process.

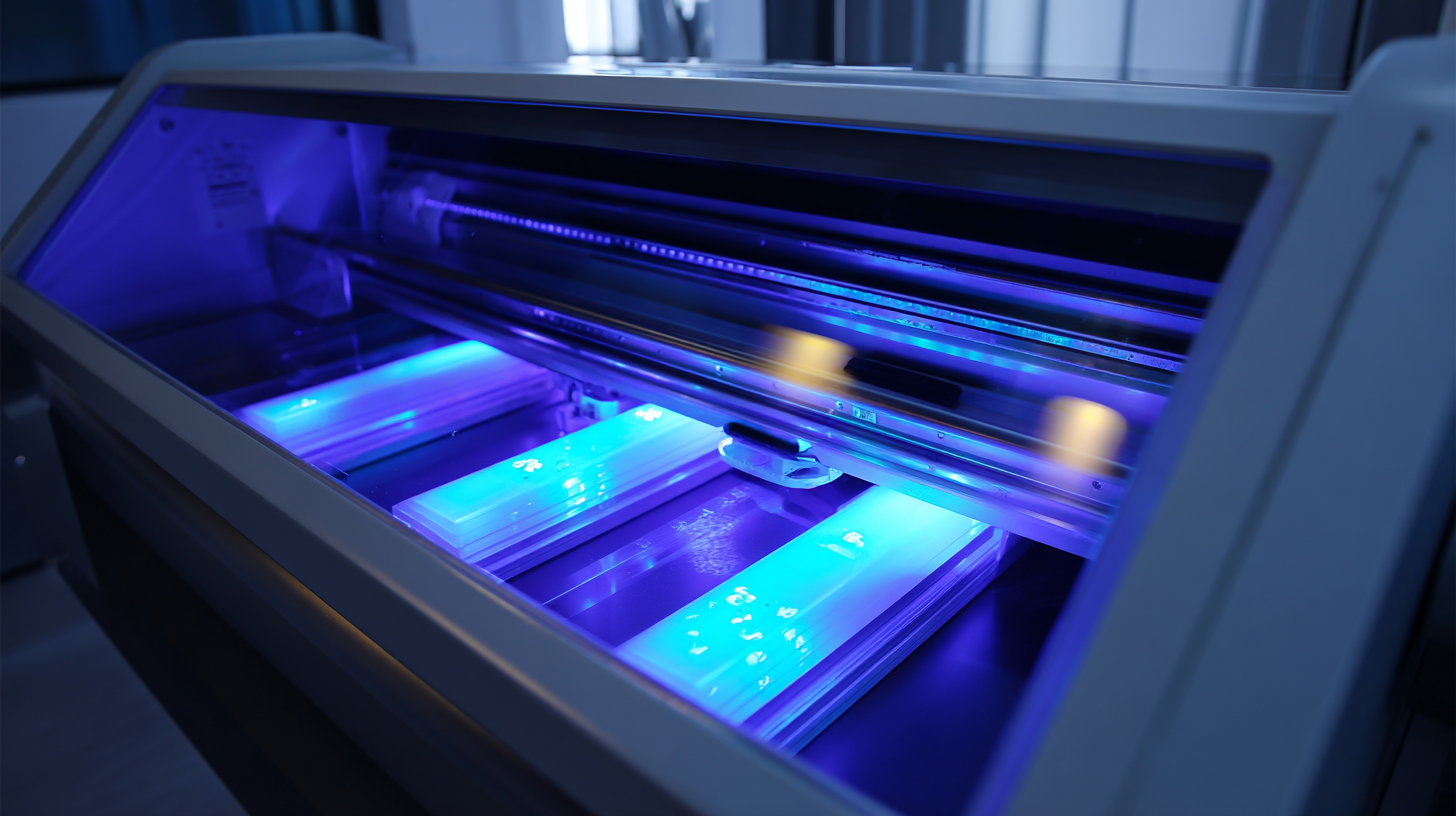

Another key trend is the integration of smart technology into UV LED curing equipment. With the rise of Industry 4.0, manufacturers are incorporating IoT capabilities that enable real-time monitoring and data analytics. These advancements provide users with valuable insights into curing performance, allowing for optimization of processes and a reduction in material waste. As automation becomes widespread, the ability to remotely manage and adjust curing parameters will further enhance operational efficiency and quality control in printing and coating applications.

When selecting UV LED curing equipment, several key features should be prioritized to enhance printing and coating efficiency. First and foremost, curing speed is critical. High-performance UV LED systems can cure inks and coatings in milliseconds, significantly reducing production time. According to a recent market analysis by Smithers Pira, manufacturers leveraging UV LED technology reported up to a 50% decrease in curing times compared to traditional UV systems. This rapid curing translates to faster print cycles and reduced bottlenecks in the production line.

Another essential aspect is the wavelength of the UV light. Most UV LED equipment operates within the 365-405 nm wavelength range, which is optimal for curing a wide variety of inks and coatings. This versatility not only extends the application scope but also minimizes the need for frequent equipment changes. Furthermore, energy efficiency is a growing concern in the industry; with UV LED curing systems consuming up to 80% less energy than conventional UV lamps, businesses can enhance sustainability while lowering operational costs, as noted in a report by the RadTech Association. Therefore, incorporating these features can significantly elevate the overall performance and efficiency of printing operations.

When it comes to UV LED curing equipment, a comparative analysis of the leading brands reveals notable differences in efficiency, durability, and cost-effectiveness. According to a recent industry report by Grand View Research, the global UV LED market is projected to reach $2.18 billion by 2026, highlighting the growing demand for reliable curing solutions across printing and coating applications. Leading brands like Phoseon Technology, Asahi UV, and LED UV Technologies are recognized for their innovative designs that offer quick curing times and reduced energy consumption, making them top contenders in the market.

Tip: When selecting UV LED curing equipment, consider the wavelength range required for specific applications. Many brands offer customizable solutions that can cure a variety of inks and coatings, enhancing overall production efficiency.

In addition to cost and efficiency, it's crucial to evaluate the after-sales support and warranty services provided by each manufacturer. A study from MarketsandMarkets indicates that companies with strong customer service yield a 15% increase in repeat business. Brands like Atlantic Zeiser not only provide high-quality products but also ensure a robust support system for their clients, further solidifying their position in the UV LED market.

Tip: Always request product demonstrations and check user reviews before making a purchase decision. Ensuring that the equipment performs well in real-world conditions can save both time and resources in the long run.

As the printing industry continues to evolve, integrating UV LED curing solutions into workflows is becoming increasingly essential for enhancing efficiency and quality. Recent predictions indicate that the LED curing market is set for substantial growth in the coming years, driven by its ability to reduce curing times and increase productivity. Industry experts have noted that this technology not only improves energy efficiency but also offers the flexibility required for various substrates, making it an attractive choice for modern printing needs.

Best practices for integrating UV LED curing solutions include reevaluating existing workflows to identify areas where these systems can be implemented for maximum impact. For instance, transitioning to UV LED curing can significantly diminish the drying time, allowing for quicker turnaround on jobs and less waste. Furthermore, leveraging data from industry reports reveals that facilities adopting these solutions can see an increase in throughput by up to 30%, showcasing the potential return on investment. As we approach key industry events, it’s crucial for companies to consider how UV LED technology can not only streamline their processes but also enhance the quality and durability of their printed products.

The future of UV LED curing technology holds remarkable potential for enhancing printing and coating efficiency. As industries strive for greater sustainability and productivity, innovations in UV LED systems are expected to play a pivotal role. These advancements include the development of higher intensity UV LEDs that cure inks and coatings more rapidly, reducing production times and energy consumption. Manufacturers are focusing on creating systems that not only improve curing speed but also maintain the quality of the final output, ensuring vibrant colors and durable finishes.

Moreover, the integration of smart technology and automation into UV LED curing equipment is set to revolutionize the industry. Real-time monitoring and feedback systems will enable operators to optimize curing parameters dynamically, enhancing precision and consistency in large-scale production. With the ongoing research into new materials and formulations compatible with UV LEDs, we are likely to see improved adhesion properties and reduced emissions, aligning with global eco-friendly practices. The next wave of innovations promises to make UV LED curing not just a choice, but a standard for efficient and sustainable printing and coating processes.