Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

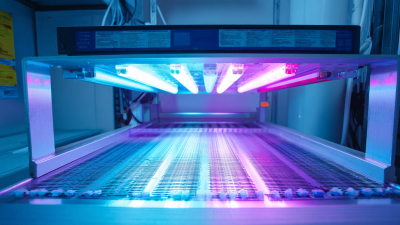

In today's fast-paced world, efficient curing and drying processes are vital across various industries, from printing to automotive. One innovative solution that has gained significant traction is the UV drying lamp. This technology employs ultraviolet light to accelerate the curing process of materials, providing a faster, more effective solution compared to traditional drying methods. Understanding how a UV drying lamp works is crucial for anyone looking to enhance their production efficiency and meet rising demand.

The UV drying lamp operates by emitting ultraviolet light, which initiates a photochemical reaction in specially formulated inks, coatings, and adhesives. This reaction quickly transforms the liquid components into a solid state, ensuring a robust and durable finish. As we delve deeper into the workings of UV drying lamps, we will explore their benefits, applications, and considerations for use, empowering businesses and individuals to make informed choices that align with their specific needs. By harnessing the power of UV technology, you can boost productivity while maintaining high quality in your projects.

A UV drying lamp is a specialized lighting device that utilizes ultraviolet (UV) light to cure or dry inks, coatings, and adhesives. These lamps emit high-intensity UV rays, which trigger photochemical reactions in specific materials, leading to a rapid drying process. Infrared heat is often used in conjunction with UV light to ensure even and effective drying across the entire surface area of the material being treated. This technology is commonly used in industries such as printing, woodworking, and automotive, where time efficiency and durability of finish are paramount.

The operation of a UV drying lamp is relatively straightforward. When the UV light is directed at a surface coated with UV-sensitive materials, the rays penetrate and initiate a chemical reaction that transforms the liquid or semi-liquid substances into a solid state. This quick curing process reduces the time required for drying, making it an ideal solution for fast-paced environments. Additionally, UV drying lamps provide a clean and environmentally friendly alternative to traditional drying methods, as they require less energy and produce minimal waste, resulting in a more sustainable operation for businesses.

Ultraviolet (UV) drying lamps have gained prominence in various industries due to their efficiency and effectiveness in curing inks, adhesives, and coatings. The underlying technology utilizes UV light to initiate a photochemical reaction, facilitating rapid drying or hardening without the need for traditional heat-based methods. A report by Smithers Pira estimates that the UV curing market is expected to grow to $3.62 billion by 2024, reflecting a robust demand for this innovative technology across sectors such as printing, automotive, and electronics.

The operation of UV drying lamps hinges on specific wavelengths of UV light, predominantly UVA and UVC. When the UV light interacts with photoinitiators in the inks or coatings, it activates a polymerization process, converting liquid substances into solid forms in a matter of seconds. This process not only enhances productivity but also reduces energy consumption, as the curing occurs at room temperature. Furthermore, a study published in the Journal of Coatings Technology highlighted that employing UV curing can lead to a reduction in volatile organic compounds (VOCs) by up to 90%, contributing to a more environmentally friendly manufacturing process.

Adopting UV drying technology can significantly optimize workflows while maintaining high-quality production standards. The speed of curing allows for quicker turnaround times, making it an attractive option for businesses looking to improve efficiency and sustainability. As industries increasingly prioritize eco-friendly solutions, the relevance of UV drying lamps continues to rise, making it a pivotal technology for the future.

UV drying lamps are widely utilized across various industries due to their efficiency and effectiveness in curing inks, coatings, and adhesives. In the printing industry, for instance, UV lamps facilitate faster drying times, significantly enhancing production capabilities. This technology allows for immediate handling of prints, reducing the risk of smudging or damage, which is especially critical in high-volume environments like commercial printing and packaging. The ability to cure materials instantly enables printers to meet tight deadlines and maintain high-quality standards.

In the manufacturing sector, UV drying lamps play a crucial role in the coating and finishing processes. Industries such as woodworking, automotive, and electronics rely on UV curing to create durable finishes that resist wear and tear. By employing UV lamps, manufacturers can achieve consistent results while minimizing energy consumption. Moreover, the precise control offered by UV technology allows for the application of thinner coatings, thereby reducing material waste and improving overall sustainability in production practices. The versatility of UV drying lamps makes them an invaluable asset across these diverse fields, addressing specific needs efficiently and effectively.

UV drying lamps offer numerous benefits across various applications, particularly in industries such as printing, coatings, and even dentistry. One of the primary advantages of using UV drying lamps is their speed and efficiency. These lamps generate ultraviolet light that rapidly cures materials, allowing processes to continue without the lengthy drying times associated with traditional methods. This quick curing not only boosts production rates but also enhances workflow efficiency, making it an attractive option for businesses looking to optimize their operations.

Another significant benefit of UV drying lamps is the quality of the finish they provide. The curing process helps to create durable, high-quality surfaces that resist scratches, chemicals, and discoloration. This is particularly important in industries where the aesthetic and longevity of the final product are crucial. Additionally, UV curing is an environmentally friendly option, as many UV drying processes emit fewer volatile organic compounds (VOCs) compared to conventional drying methods. This reduction in harmful emissions contributes to a safer working environment and aligns with sustainability goals that many organizations are striving to achieve.

Operating and maintaining UV drying lamps effectively is crucial to ensure optimal performance and longevity. One of the best practices involves regular inspection of the lamp's components, including the bulb and electrical connections. Checking for any signs of wear or damage can prevent unexpected failures during operation. It is also essential to maintain a clean environment around the lamp, as dust and debris can obstruct the UV light and impact the drying process. Using designated cleaning materials that do not leave residues is advisable to avoid affecting the lamp’s efficiency.

Moreover, proper operational protocols must be established when utilizing UV drying lamps. Operators should adhere to recommended exposure times and distances specified for the materials being cured. It's important to conduct tests to determine the perfect settings for specific applications, ensuring maximum effectiveness without overexposure, which can damage both the materials and the lamp itself. Finally, training personnel on safety measures, including the use of protective gear, will help mitigate risks associated with UV exposure while maximizing the benefits of the drying process.