Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of modern manufacturing and curing processes, the UV Curing Flood Lamp has emerged as a vital technology. This innovative tool utilizes ultraviolet light to initiate chemical reactions in various materials, facilitating rapid curing or hardening. By understanding the fundamental principles and functionalities of the UV Curing Flood Lamp, industries can enhance their production efficiency and product quality.

At its core, the UV Curing Flood Lamp operates by emitting UV light across a designated area, enabling it to cure coatings, adhesives, and other materials uniformly. This process not only accelerates curing times significantly but also minimizes the need for solvents, contributing to more eco-friendly manufacturing practices. As we delve deeper into the mechanics of this advanced technology, we will explore its advantages, applications, and the science behind its effectiveness, demonstrating the indispensable role it plays in contemporary industrial settings.

A UV curing flood lamp is a specialized device designed to emit ultraviolet (UV) light, which is used to cure or harden photosensitive materials in various industrial applications. This technology has gained significant traction in sectors such as printing, coatings, and adhesives due to its efficiency and speed. According to a report by Research and Markets, the global UV curing equipment market is expected to grow from $3.5 billion in 2020 to over $5 billion by 2025, highlighting the increasing demand for faster curing processes and environmentally friendly solutions.

UV curing flood lamps operate by emitting a broad spectrum of UV light, typically in the UV-A range, which activates photoinitiators in the coating or adhesive materials. This reaction transforms the liquid formulation into a solid state almost instantaneously. Unlike traditional curing methods that may take several hours, UV curing can achieve complete curing within seconds to minutes, significantly improving production efficiency. Additionally, UV curing offers the advantage of being a solvent-free process, aligning with the industry's move towards more sustainable practices by reducing volatile organic compound emissions, as referenced in findings from the EPA.

The versatility of UV curing flood lamps is notable, as they can be used on a variety of substrates, including paper, plastic, metal, and glass. This adaptability makes them essential in industries ranging from automotive to electronics, where precise and durable finishes are critical. The increased adoption of UV technology can also be attributed to its cost-effectiveness, with reduced energy consumption and material waste, as reported in industry analyses.

UV curing technology is revolutionizing various industries, including printing, coatings, and adhesives, due to its efficiency and environmental benefits. This technology utilizes ultraviolet light to initiate a photochemical reaction that quickly transforms liquid substances into solid forms. According to a report by Smithers Pira, the global UV curing market is expected to reach $2.3 billion by 2024, reflecting a compound annual growth rate (CAGR) of over 8% from 2019. This growth is driven by the increasing demand for quick-drying, durable finishes in manufacturing processes.

The science behind UV curing involves the use of specialized UV lamps that emit light at specific wavelengths. When materials designed to be cured are exposed to this light, photoinitiators within the substance absorb the UV energy and produce free radicals. These free radicals initiate a polymerization process, where monomers link together to form a solid polymer matrix. Studies indicate that UV curing can reduce energy consumption by up to 50% compared to traditional drying methods, making it a preferred choice in many applications. Additionally, UV-cured products often exhibit superior adhesion, chemical resistance, and scratch resistance, which further contributes to the technology’s popularity in diverse sectors.

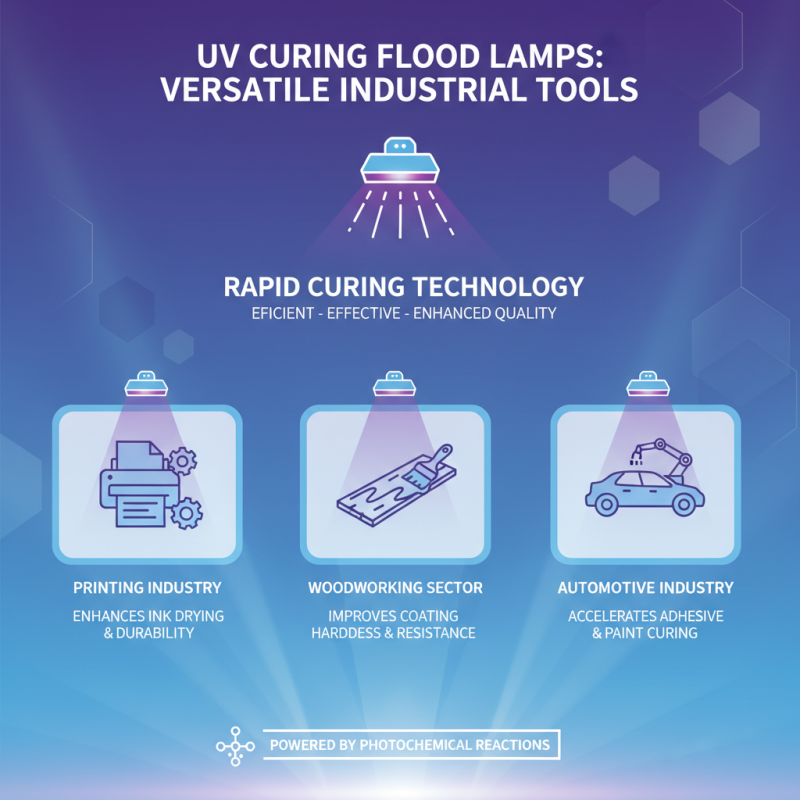

UV curing flood lamps are versatile tools utilized across various industries for their efficient and effective curing capabilities. These lamps emit ultraviolet (UV) light, which triggers photochemical reactions in UV-sensitive materials, leading to rapid drying or hardening processes. In manufacturing sectors, such as printing, woodworking, and automotive, UV curing flood lamps are instrumental in enhancing the quality and durability of coatings, inks, and adhesives.

In the printing industry, for instance, UV curing flood lamps ensure that inks adhere firmly to surfaces, enabling vibrant prints with a glossy finish. Moreover, these lamps find applications in woodworking, where they cure finishes and adhesives quickly, significantly reducing production time. In the automotive sector, UV curing is employed in the application of protective coatings, ensuring that vehicles are both aesthetically pleasing and resistant to wear. As technology advances, the integration of UV curing flood lamps continues to evolve, leading to improved efficiency and sustainability in various applications.

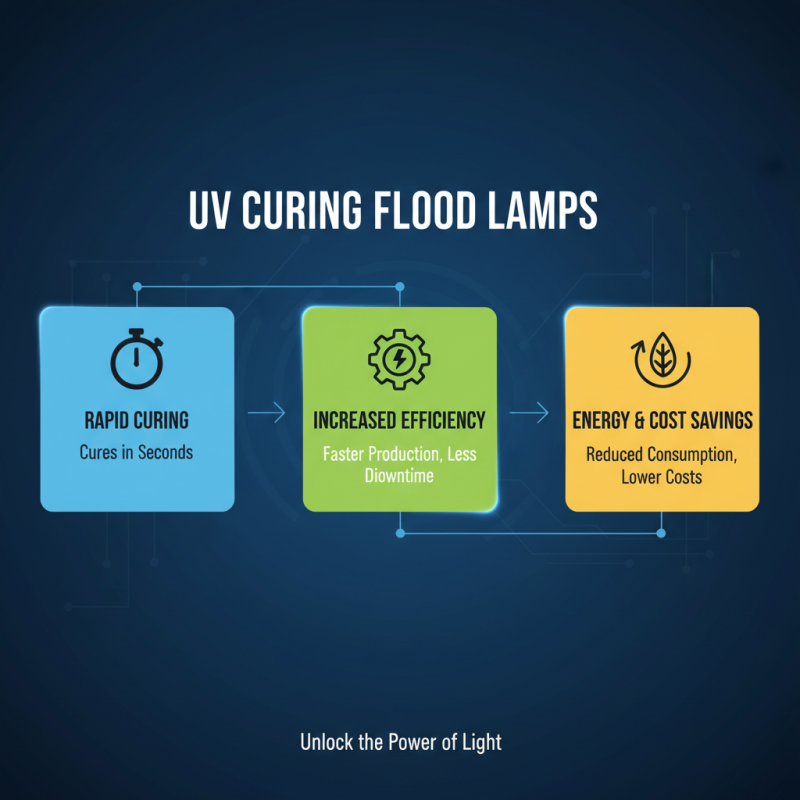

UV curing flood lamps have become increasingly popular in various industries due to their ability to quickly and efficiently cure coatings, inks, and adhesives. One of the primary advantages of using these lamps is their rapid curing process. Traditional curing methods often require long drying times, which can lead to increased production times and costs. In contrast, UV curing flood lamps emit ultraviolet light that instantly triggers a photochemical reaction, allowing materials to cure in just seconds. This efficiency not only speeds up production but also reduces energy consumption in the long run.

Another significant benefit of UV curing flood lamps is their ability to produce high-quality finishes. The ultraviolet light ensures uniform curing across the surface, minimizing the risk of imperfections often seen with traditional methods. Additionally, the chemical composition of UV-cured products typically leads to enhanced durability and resistance to harsh environmental conditions. This characteristic is particularly beneficial for industries that require robust and long-lasting coatings, such as automotive and aerospace manufacturing. In conclusion, the advantages of UV curing flood lamps—rapid curing times and superior finish quality—make them an invaluable tool for modern production processes.

When working with UV curing flood lamps, safety should always be a top priority. These devices emit ultraviolet radiation, which can be harmful to the skin and eyes if proper precautions are not taken. Always wear appropriate personal protective equipment (PPE), such as UV-blocking goggles and gloves, to minimize exposure. Additionally, ensure that the workspace is well organized and that all personnel are aware of the potential hazards.

Tips for safe operation include conducting a risk assessment before starting any UV curing process. This includes evaluating the environment for flammable materials and ensuring adequate ventilation. Furthermore, it is advisable to use UV curing lamps with built-in safety features, such as automatic shut-off switches and protective shielding, to reduce the risk of accidental exposure.

It’s also crucial to educate all team members on the correct usage of UV curing equipment. Regular training sessions on best practices and emergency procedures can help create a safer work environment. Implementing clear protocols for handling and emergency situations can greatly enhance safety standards when using UV curing flood lamps.