Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of manufacturing and DIY projects, the choice of tools and technologies can significantly impact the final outcome. Among the various options available, Curing UV Lamps have emerged as a powerful solution for those looking to enhance their projects with efficiency and precision. These lamps utilize ultraviolet light to cure materials such as inks, resins, and coatings rapidly, offering numerous advantages over traditional drying methods.

The effectiveness of Curing UV Lamps lies in their ability to initiate photochemical reactions that harden or "cure" substances almost instantly. This capability not only speeds up production times but also improves the durability and quality of the finished product. As creative professionals and hobbyists seek ways to innovate and optimize their processes, understanding the benefits of Curing UV Lamps becomes essential. By exploring the applications and advantages of these versatile tools, individuals can unlock new possibilities and ensure superior results in their projects. Whether you're involved in professional manufacturing or enthusiastic crafting, integrating Curing UV Lamps into your workflow could be a game-changer.

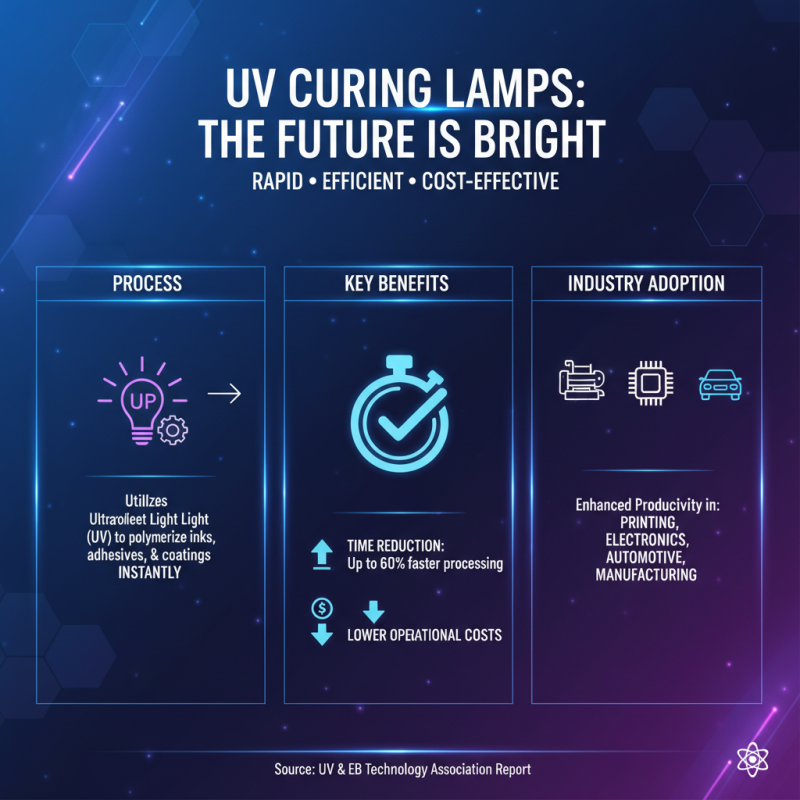

Curing UV lamps have become increasingly popular in various industries due to their efficiency and effectiveness in achieving rapid curing processes. By utilizing ultraviolet light, these lamps can polymerize inks, adhesives, and coatings in a fraction of the time it would take with conventional drying methods. According to a report by the UV & EB Technology Association, businesses that adopt UV curing technologies can reduce processing times by up to 60%, leading to enhanced productivity and lower operational costs.

One of the most significant benefits of using curing UV lamps is their environmental impact. The UV curing process typically involves low volatile organic compounds (VOCs), which helps in maintaining air quality and compliance with environmental regulations. A report from the American Coatings Association indicates that the implementation of UV curing can lead to a 40% reduction in VOC emissions compared to traditional solvent-based methods. This not only benefits the environment but also aligns with many companies' sustainability goals.

Tips: When considering UV lamps for your projects, ensure that you select the appropriate wavelength for your specific curing needs. Additionally, always conduct tests to determine optimal curing times and distances, as factors such as substrate type and lamp intensity can significantly affect results. It's also beneficial to stay updated on technological advancements, as innovations in UV curing can further enhance efficiency and output quality.

Ultraviolet (UV) curing technology has rapidly gained traction across various industries, from manufacturing to art applications. At its core, UV curing lamps utilize short wavelengths of UV light to initiate a photochemical reaction that enables the rapid curing of coatings, inks, adhesives, and other materials. According to a market research report by Smithers Pira, the global UV curing market is projected to reach $1.3 billion by 2025, showcasing a compound annual growth rate (CAGR) of 10.7% from 2020 to 2025. This growth is largely attributable to the increasing demand for sustainable and efficient curing technologies, as UV curing significantly reduces energy consumption compared to conventional drying methods.

The technology operates on a simple principle: when UV light is applied, it triggers molecules in the coating or ink to cross-link, leading to a solid and durable finish almost instantly. This quick curing process not only enhances production speeds, but it also minimizes the emissions of volatile organic compounds (VOCs), aligning with increasing environmental regulations. A report by the American Coatings Association indicates that UV-cured products typically emit 50% fewer VOCs than traditional solvent-borne systems, making them a more eco-friendly choice for manufacturers striving to meet stringent environmental standards. As industries continue to evolve and prioritize sustainability, understanding the mechanics behind UV curing will ensure that businesses can leverage this technology for greater efficiency and environmental compliance.

Curing UV lamps have gained tremendous traction across various industries due to their efficiency and versatility. In the printing industry, for instance, UV curing technology enables rapid drying of inks on varied substrates, significantly reducing production time. According to a report by Freedonia Group, the global UV printing market was projected to reach $3.5 billion by 2025, showcasing the growing preference for materials that can withstand high-speed production demands and offer outstanding quality. This shift toward UV inks not only enhances print durability but also improves the ecological footprint of printing processes by minimizing volatile organic compounds (VOCs).

Beyond printing, the adhesive and coatings sectors leverage curing UV lamps to accelerate the production of durable and high-performance products. In aerospace and automotive industries, UV-curable adhesives are increasingly replacing thermal-curing counterparts due to their rapid set times and superior bond strengths. A study by Technavio indicated that the global UV adhesives market is expected to grow by nearly $1 billion from 2020 to 2024, primarily driven by the rise in demand for high-performance bonding solutions. By utilizing curing UV lamps, manufacturers streamline operational efficiency while enhancing product performance, enabling a more sustainable production process with fewer energy demands.

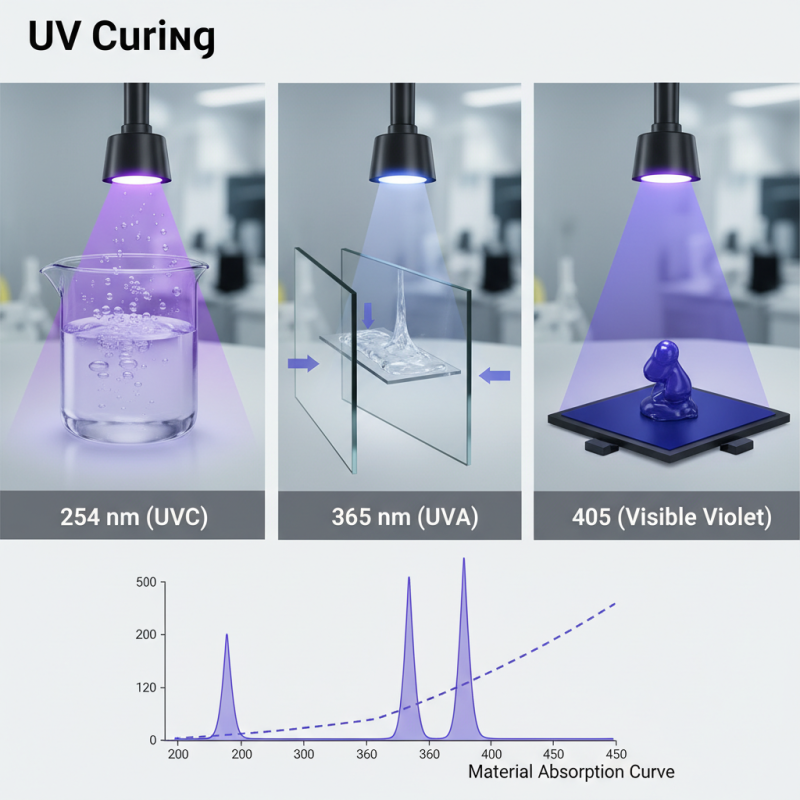

When selecting UV curing lamps for your projects, several critical factors must be taken into account to ensure optimal results and efficiency. One of the primary considerations is the wavelength of the UV light. Different materials require specific wavelengths to achieve effective curing. For instance, most UV curing applications operate within the 200 to 400 nm range, with a peak efficacy often around 365 nm for many commercial coatings and adhesives. According to a report by the UV & EB Technology Alliance, the right wavelength can significantly enhance the curing speed and quality, highlighting the importance of matching the UV source to the material requirements.

Another essential factor to consider is the intensity of the UV light. The curing process is not only about the wavelength but also the amount of energy delivered to the surface. Research indicates that higher intensity lamps can reduce curing times and improve adhesion properties. A study published in the Journal of Polymer Science found that UV light intensity directly influences the crosslinking density in polymers, which can enhance the durability and performance of the final product. Therefore, understanding the required intensity based on the specific project parameters can lead to better outcomes.

Finally, the operational cost and longevity of the UV lamps should not be overlooked. LED UV curing technology has gained popularity because of its lower energy consumption and longer lifespan compared to traditional mercury vapor lamps. Data from industry analysts suggest that LED UV lamps can reduce operational costs by up to 70%, making them a more sustainable choice for long-term projects. Balancing these factors—wavelength, intensity, and operational efficiency—will help in selecting the most suitable UV curing lamp for your needs.

When using curing UV technology, safety should always be a primary concern. First and foremost, it is crucial to wear appropriate personal protective equipment (PPE), which includes UV-blocking eyewear and gloves. These items shield the skin and eyes from potential UV radiation exposure. Additionally, ensure that your work area is well-ventilated to avoid the accumulation of any fumes released during the curing process. Keeping a safe distance from the UV source while the lamp is in operation also minimizes risk, ensuring that you can work effectively without compromising your health.

To achieve the best results with curing UV lamps, it’s essential to understand the material you are working with. Different substrates can react uniquely to UV light, and therefore, selecting the right resin or coating for your project is vital. Conducting small tests before fully applying your material helps gauge curing times and the effectiveness of the process. Moreover, maintaining the cleanliness of the lamp and work surface can enhance the curing process, allowing for better adhesion and finish quality. By following these tips, you can maximize the effectiveness of your projects while ensuring a safe working environment.

| Aspect | Description | Tips |

|---|---|---|

| Curing Speed | UV lamps significantly reduce curing time compared to traditional methods. | Use lamps with a specific wavelength that matches your resin for optimal results. |

| Energy Efficiency | Curing UV technology consumes less power than conventional curing methods. | Choose LED UV lamps for enhanced energy savings and longer lifespan. |

| Safety Considerations | UV radiation can be harmful; proper precautions are necessary. | Always wear UV protective gear and goggles when operating UV lamps. |

| Material Compatibility | Not all materials are suitable for UV curing; check compatibility. | Conduct a small test on materials before full application. |

| Post-Cure Effectiveness | Post-curing increases hardness and durability. | Consider additional curing under UV light to enhance final product quality. |