Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

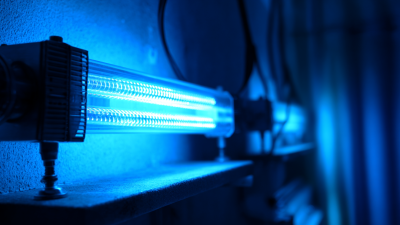

In recent years, the manufacturing and printing industries have witnessed a significant transformation with the advent of UV drying lights. These advanced curing systems offer unparalleled efficiency, quality, and environmental benefits compared to traditional drying methods. According to a report by Smithers Pira, the global UV curable inks and coatings market is projected to grow at a compound annual growth rate (CAGR) of 9% through 2025, driven primarily by the increasing adoption of UV drying light technology. This method not only accelerates the drying process but also enhances the durability and adhesion of various coatings, making it essential for industries ranging from automotive to packaging. As businesses strive for sustainability and operational efficiency, the implementation of UV drying light systems presents a viable solution that aligns with both environmental standards and consumer demands for high-quality products.

The evolution of UV drying lights has significantly transformed industrial curing processes, enhancing efficiency and product quality across various sectors. Traditional drying methods often faced limitations concerning speed and energy consumption, but recent advancements in UV LED technology allow for rapid curing with lower energy requirements. These innovations enable manufacturers to achieve quicker production cycles while minimizing environmental impact, marking a substantial shift in curing methodologies.

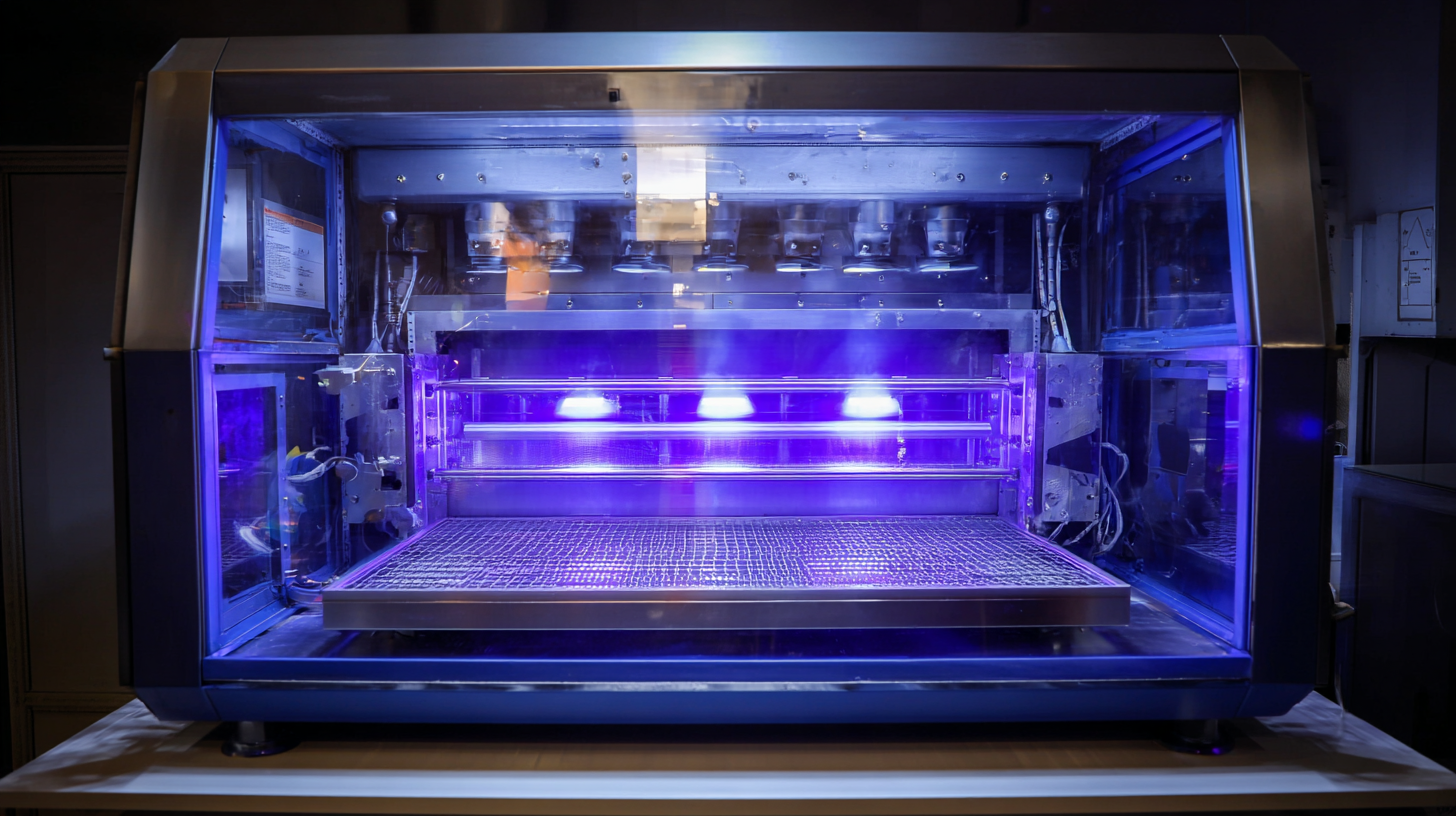

Moreover, the integration of dual-cure resins in UV curing processes is addressing challenges such as fiber volume fraction control and void content minimization in composite materials. The development of new techniques in additive manufacturing, particularly for continuous carbon fiber thermoset composites, exemplifies how UV curing is becoming essential in optimizing the mechanical properties of materials. As industries increasingly adopt UV drying lights, we can anticipate further advancements that will not only improve curing techniques but also expand the possibilities of material applications and functionalities, heralding a new era in manufacturing.

UV light curing has emerged as a game-changer in various industries, offering several key advantages over traditional curing methods. One of the most significant benefits is the speed of the curing process. UV light can cure coatings, inks, and adhesives in mere seconds, which drastically reduces production times and increases efficiency. In contrast, traditional methods often require longer drying times, leading to bottlenecks in workflow and increased labor costs. This rapid curing capability not only enhances productivity but also allows for quick turnaround times, which is essential in today’s fast-paced market.

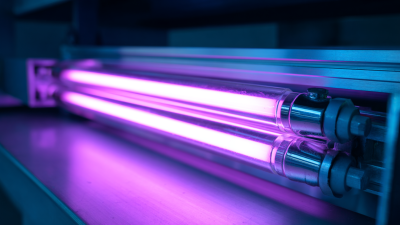

Another advantage of UV curing lies in its environmental impact. UV light curing systems generally require fewer volatile organic compounds (VOCs) compared to traditional solvents and heat-based methods. This reduction in VOCs leads to a safer working environment and helps manufacturers adhere to stricter environmental regulations. Additionally, since UV-cured products are less prone to defects such as bubbling or cracking, the resulting quality is often superior, with enhanced durability and performance. This dual benefit of sustainability and quality makes UV light curing a preferred choice for many industries, from automotive to packaging and beyond.

Ultraviolet (UV) light curing has emerged as a transformative technology in various industries, significantly enhancing curing efficiency. By utilizing UV light, materials such as polyurethane-urea adhesives are rapidly polymerized, resulting in quicker processing times and improved chemical resistance. Recent studies have demonstrated that optimizing factors like the concentration of photoinitiators and temperature can lead to superior performance in UV light-responsive applications. For instance, it was found that an optimal photoinitiator concentration of around 3% at 30°C yielded the best results, eliminating concerns of thermal polymerization during the curing process.

**Tips:** When working with UV curing systems, ensure proper safety measures are in place, as exposure to UV light can be harmful. Additionally, fine-tuning the photoinitiator concentration can greatly impact the curing speed and the mechanical properties of the final product, so it’s wise to conduct small-scale tests before full-scale implementation.

Increasingly, applications of UV curing technology are found in innovative materials beyond traditional adhesives. Bio-inspired UV-curing composites have been explored for lithium extraction, demonstrating the versatility of UV light in material science. Furthermore, advancements in sustainable building materials are being explored, with a focus on UV-cured products that not only improve structural performance but also contribute to environmentally friendly practices.

**Tips:** Always keep an eye on emerging trends in materials science, as the integration of UV curing with other technologies can lead to novel applications. Regularly assess the compatibility of different substrates with UV-curing systems to optimize adhesion and performance in specialized applications.

The UV curing technology market is witnessing significant growth, driven by its efficiency and environmental benefits. As per industry reports, the UV curable resins market is expected to see robust expansion, with compositions including monomers, oligomers, and photo-initiators attracting substantial attention. The sector is projected to grow at a considerable pace, reflecting the increasing adoption of UV curing processes across various applications such as wood, plastics, and electronics.

Furthermore, the UV curable coatings market is on track for an impressive CAGR of 12.2%. This surge can be attributed to the rising demand for fast-drying and durable finishes in manufacturing sectors. With environmental sustainability in focus, businesses are increasingly opting for UV curing technologies, which not only reduce volatile organic compounds (VOCs) but also enhance production efficiency. As industries adapt to these advancements, the market for UV curing systems is set to broaden, demonstrating an enduring trend towards innovation in curing processes.

Incorporating UV drying lights into production settings can significantly enhance the efficiency of curing processes. According to a 2022 report from the RadTech organization, the adoption of UV technology has grown by over 20% in the last five years across various industries, particularly in printing and coatings. This rise is attributed to UV drying lights' ability to accelerate cure times, allowing manufacturers to increase throughput and improve overall productivity. The technology can cure inks and coatings in seconds, compared to traditional methods which can take several minutes or even hours.

To optimize the use of UV drying lights, it's essential to understand the importance of light intensity and wavelength. Research indicates that using a wavelength of 200-300 nm maximizes the efficiency of curing processes, as this range aligns perfectly with most photoinitiators used in UV formulations. Furthermore, maintaining the correct distance between the light source and the substrate—between 6 to 12 inches—can greatly affect curing uniformity and quality. Properly adjusting these parameters based on material type and thickness can help ensure consistent results while minimizing production defects.