Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

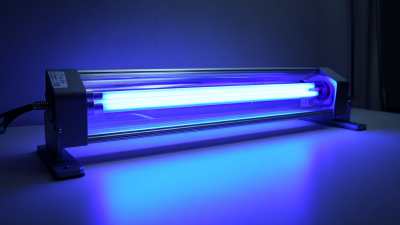

The world of UV LED curing technology is rapidly evolving. According to a recent industry report by MarketsandMarkets, the UV LED curing market is projected to reach $3.53 billion by 2026. This significant growth highlights the increasing demand for UV LED curing devices across various sectors, including printing, coatings, and adhesives. Businesses are seeking efficient solutions, and UV LED curing devices have emerged as powerful tools for fast and effective curing processes.

However, the market is not without its challenges. Users must consider factors such as equipment cost, energy consumption, and the need for specialized training. Not all UV LED curing devices offer the same performance, and the selection process can be daunting. Companies often face the risk of investing in technology that may not meet their specific needs or adapt well to evolving production requirements.

As we explore the top UV LED curing devices in 2026, it's essential to analyze these factors carefully. The journey toward finding the perfect UV LED curing device may involve trial and error. Ultimately, informed decisions will be critical to leveraging the full potential of this innovative technology.

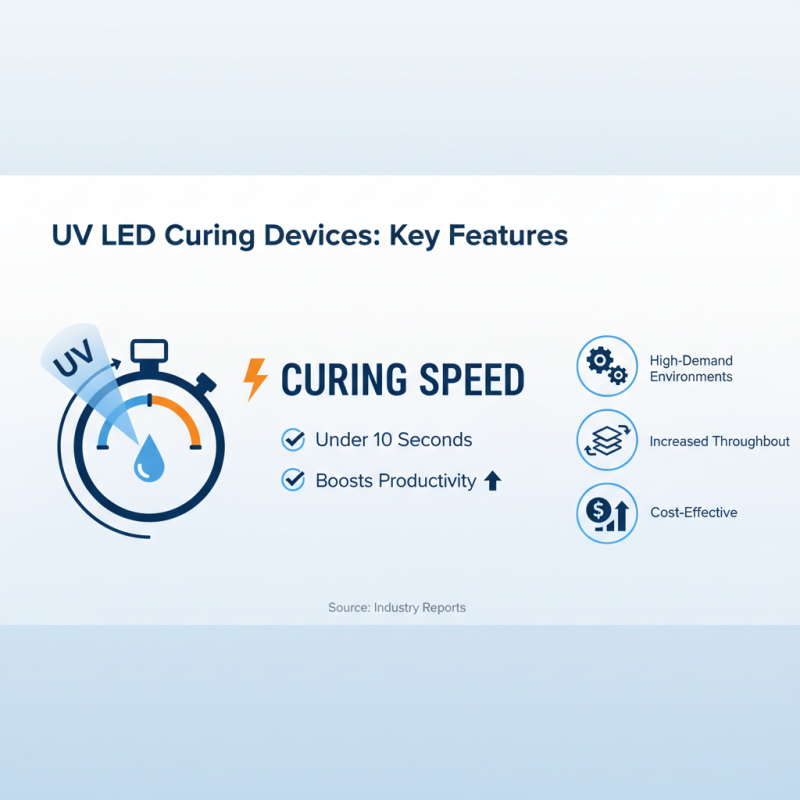

When considering UV LED curing devices, several key features stand out. The curing speed is crucial. Devices that offer faster curing times can significantly enhance productivity. According to industry reports, devices that cure in under 10 seconds are gaining popularity. This speed is vital for high-demand environments.

Energy efficiency matters too. Many modern devices use up to 80% less energy than traditional options. This reduction not only lowers operational costs but also lessens environmental impact. Additionally, consider the wavelength capabilities. Devices with dual wavelengths can accommodate various materials, making them more versatile in applications like printing and coating.

Tips: Look for adjustable intensity settings. This feature allows you to control the curing process for different substrates. It could help achieve better results with less trial and error. Another aspect to ponder is the maintenance aspect. Devices that are hard to clean or maintain can lead to downtime and inefficiency. Reflect on the long-term costs associated with maintenance before making a choice.

The UV LED curing market is evolving rapidly. Various brands are paving the way with innovative technologies. Each player brings unique offerings, enhancing productivity and efficiency in various sectors. Companies are focusing on low-energy consumption. This trend aligns with a growing emphasis on sustainability. Advanced designs are making devices smaller and more versatile.

Tips: Look for energy-saving features. They can significantly reduce long-term costs. Consider the device's curing speed, as faster options may boost productivity.

Brand competition drives innovation. Some firms are enhancing user-friendly interfaces. This improvement makes these devices easier to operate for everyone. Customers are increasingly looking for portable options. Smaller devices are ideal for limited workspace.

Tips: Check customer reviews for real-world performance insights. They often reveal aspects that specifications may overlook. Prioritize flexibility; devices that can cure multiple materials can offer better value.

UV LED curing technology has evolved significantly as of 2026. Many industries rely on these devices for various applications.

Technologies differ in terms of efficiency and performance. The market is projected to grow at a CAGR of 12% from 2021 to 2026, according to recent industry reports.

This growth indicates a rising demand for various UV LED curing methods.

Among available options, the two primary technologies are conventional UV curing and UV LED curing.

Conventional UV curing systems often generate more heat, which can affect sensitive substrates.

In contrast, UV LED curing provides a cooler environment. This feature is particularly important in industries like printing and coatings, where temperature sensitivity matters.

Tip: For effective application, ensure that your substrate is compatible with the chosen UV curing method.

A mismatch can lead to unsatisfactory results.

Despite the advantages of UV LED curing, some gaps remain. Initial costs can be higher compared to traditional methods.

Furthermore, not all UV LED devices deliver consistent results across different materials.

Users should assess their specific needs carefully.

Tip: Always conduct small-scale tests before fully committing to a new technology.

This practice can save costs and time.

UV LED curing technology is gaining traction across various industries. Its applications range from printing to electronics and even healthcare. In the printing sector, it enhances drying speeds significantly. Fast-drying inks lead to quicker product turnovers. This efficiency can reduce workflow bottlenecks, but not every printing scenario fully embraces this technology.

In electronics, UV LED curing plays a crucial role in adhesives and coatings. It ensures robust bonding for circuit boards. The precision in curing improves overall product durability. However, not all materials are compatible with this process. Manufacturers must often trial different formulations. This can be time-consuming and sometimes frustrating.

The healthcare industry is exploring UV LED curing for sterilization and medical device manufacturing. Its ability to quickly cure coatings on devices is impressive. However, there are concerns about long-term safety. This lingering uncertainty may slow down widespread adoption. As industries navigate these applications, the balance between innovation and practicality remains a challenge.

This chart illustrates the projected market growth of UV LED curing applications across various industries in 2026. The automotive and electronics sectors are expected to lead the market, while the food packaging industry shows significant potential for growth as well.

The UV LED curing technology landscape is rapidly evolving. By 2026, experts predict a significant rise in adoption across various industries. Market research indicates that the global UV curing market is expected to reach $5.8 billion by 2026. This suggests a growing demand for more efficient curing solutions in printing, coatings, and adhesives.

One emerging trend is the development of more energy-efficient UV LED devices. Studies show that these systems use up to 80% less energy than traditional mercury-based UV lamps. In addition, they have a longer lifespan, reducing operational costs. However, some users still express concerns about the initial investment of UV LED systems. The uncertainty surrounding return on investment is a common point of reflection.

Another innovation is the introduction of hybrid systems that combine UV LED with traditional curing methods. This approach offers flexibility but raises questions about compatibility and effectiveness. Industry players need to consider whether this mixed-tech path meets their needs. Short-term gains versus long-term sustainability must be evaluated, especially as market demands shift toward green technologies.

| Device Type | Wavelength (nm) | Power (W) | Curing Time (s) | Applications |

|---|---|---|---|---|

| Handheld Curing Lamp | 365 | 10 | 5 | Nail Art, Small Repairs |

| Desktop Curing Unit | 395 | 50 | 10 | 3D Printing, Coatings |

| Industrial Curing System | 405 | 200 | 3 | Large Scale Manufacturing |

| Compact Curing Device | 375 | 30 | 8 | Labels, Packagings |

| Portable UV Printer | 385 | 20 | 15 | Customized Prints, Decor |