Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving world of adhesive technology, UV glue curing lamps have emerged as essential tools. According to recent industry reports, the global UV curing market is projected to reach $9.5 billion by 2027. This growth reflects the increasing demand for efficient bonding solutions in various sectors, from automotive to electronics. As noted by Dr. Alex Reynolds, a leading expert in adhesive technology, “The right UV glue curing lamp can revolutionize the way we approach bonding.”

These lamps harness UV light to cure adhesives, creating strong bonds in seconds. Their ability to bond a variety of materials makes them invaluable. However, not all UV glue curing lamps offer the same performance. Crafting strong, reliable bonds requires understanding the nuances of each product. In a market filled with options, consumers often face confusion when selecting the best lamp.

Balancing UV intensity, exposure time, and material compatibility is crucial. A poor choice can result in weak bonds or extended curing times. Investing in the right UV glue curing lamp can prevent these issues. Reflecting on these complexities leads to more informed decisions.

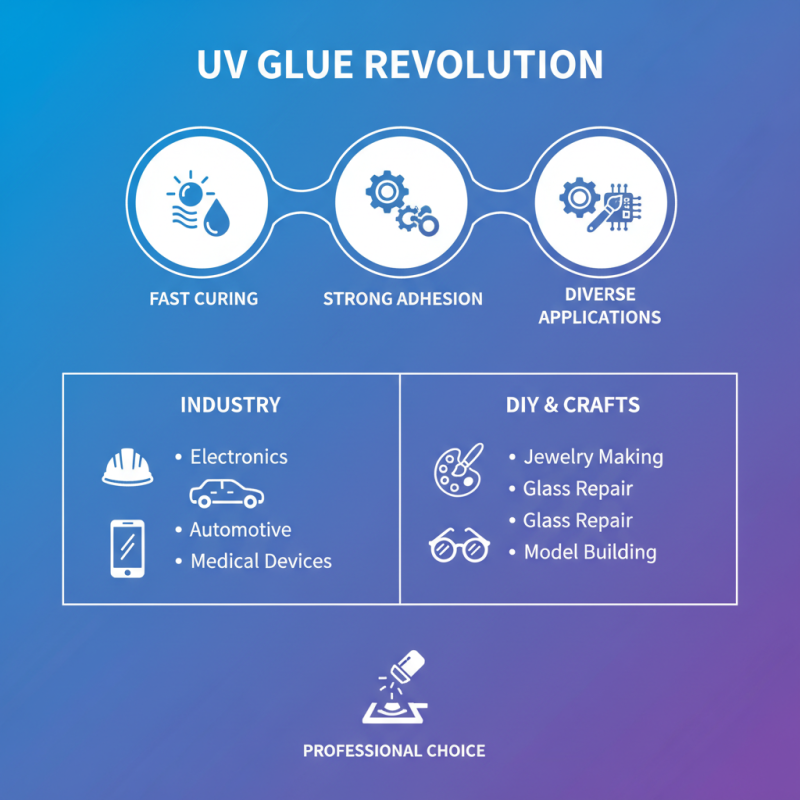

UV glue has revolutionized the bonding industry. This type of adhesive cures quickly when exposed to UV light. Its applications are diverse, ranging from industrial settings to arts and crafts. Many professionals prefer this glue for its strong bonding capabilities.

When using UV glue, proper equipment is essential. Curing lamps play a crucial role in the effectiveness of UV adhesives. The right lamp can enhance bonding quality significantly. However, some users overlook lamp specifications, leading to subpar results. This oversight can lead to weak joints that may fail over time.

Different projects require different approaches. The thickness of the adhesive layer, for instance, impacts curing. Users often apply too much glue, thinking it improves strength. Unfortunately, this can cause incomplete curing, leaving parts unbonded. Understanding UV glue's properties helps in achieving better outcomes. In the end, relying on UV glue and its curing lamps takes practice and refinement.

UV curing is a fascinating process that revolutionizes how adhesives bond. When UV light hits a special adhesive, it triggers a chemical reaction. This reaction turns liquid adhesives into durable solids. Studies indicate that UV-curable adhesives can achieve up to 90% of their final strength within seconds. This rapid curing time offers significant efficiency in production settings.

However, not all UV adhesives behave the same way. Some may require specific wavelengths of light for optimal curing. Differences in chemical formulations can lead to inconsistent results. A report from an industry expert suggests that improper UV exposure can cause weak bonds, making it essential to match adhesives with the right curing lamp.

While UV curing has great advantages, it also poses challenges. For instance, inadequate surface preparation can hinder adhesion. Similarly, the surrounding temperature and humidity levels can affect curing rates. These factors often get overlooked but are crucial for achieving the strongest bond. By understanding these nuances, professionals can enhance their bonding solutions and minimize failures.

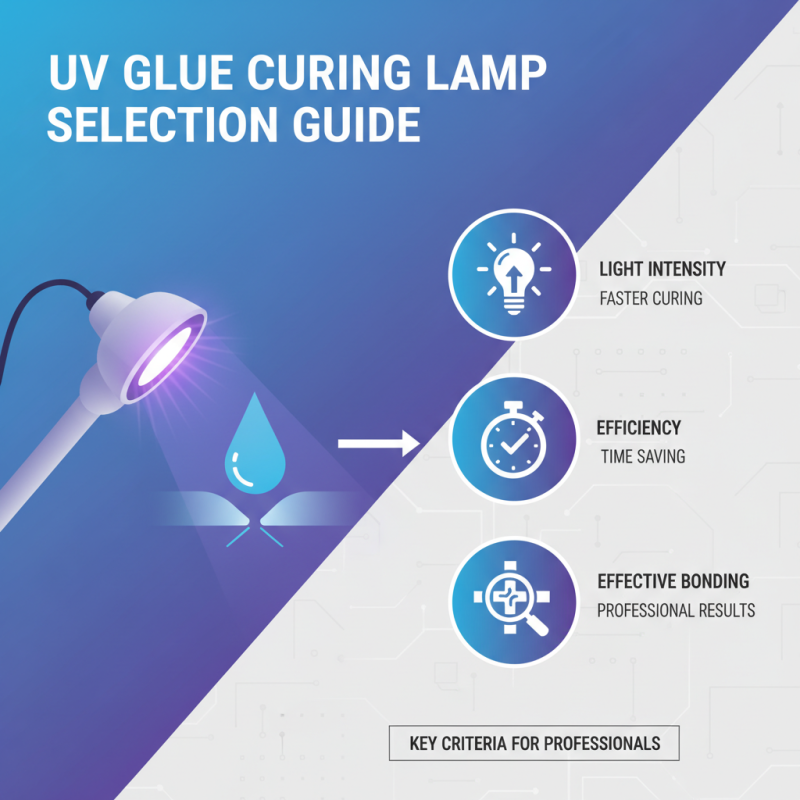

Choosing the right UV glue curing lamp is essential for effective bonding. Professionals often consider several criteria. Light intensity is crucial. A lamp with higher intensity cures adhesives faster. This feature saves time and improves efficiency in projects.

Another important factor is the wavelength range. Different adhesives require specific wavelengths for optimal curing. A versatile lamp can accommodate various glues. Portability also matters. A lightweight, compact lamp is easier to handle in different work environments. This adaptability is vital for professionals on the go.

Consider the heat output too. Excessive heat can damage delicate materials. An ideal lamp balances heat without compromising performance. Durability is a key aspect as well. A reliable lamp withstands daily wear and tear. Reflecting on these criteria ensures you make an informed decision. Ultimately, investing in the right lamp can elevate your work quality.

When selecting UV glue curing lamps, performance, wavelength, and efficiency play critical roles. The ideal wavelength for curing UV adhesives typically ranges from 320 to 400 nm. This range effectively initiates the polymerization of photoinitiators, leading to strong and durable bonds. According to industry data, lamps emitting in this spectrum can enhance curing speed by 30% to 50%, improving overall efficiency.

Comparative studies emphasize that different lamp technologies impact adhesive performance. For instance, LED lamps have shown a longer lifespan, lasting up to 25,000 hours. On the other hand, traditional mercury lamps offer higher output in some cases but may degrade faster. Efficiency varies too; some models reach 90% energy conversion, while others lag at 70%. This variation reflects the need for careful consideration when choosing a lamp.

Moreover, users may encounter challenges with heat management. Some high-output lamps can overheat substrates, risking damage to sensitive materials. This aspect remains a critical concern in many applications. A balanced selection of the right lamp can lead to improved bonding results, yet challenges still exist. Evaluating performance and efficiency is not always straightforward. The best choice may depend on specific project needs and constraints.

When using UV glue curing lamps, safety should always be a priority. Always wear protective eyewear. UV light can harm your eyes. Ensure the workspace is well-ventilated. This helps reduce the risk of inhaling harmful fumes. Avoid direct skin exposure to the lamp's light. Protective gloves are also recommended. Skin burns can occur with prolonged exposure.

It's essential to examine the equipment regularly. A faulty lamp can lead to uneven curing. This may weaken the bond, resulting in project failure. Keep the workspace organized. A cluttered area can lead to accidents. Be mindful of the curing time recommended for each adhesive. Over-curing can create brittle bonds. Each application may differ, so adjustments are necessary. Always test a small area first to see if the results meet your expectations. Requesting feedback from peers can also help improve techniques.

| Lamp Model | Wavelength (nm) | Curing Time (seconds) | Power (W) | Weight (lbs) | Features |

|---|---|---|---|---|---|

| Model A | 365 | 10 | 36 | 2.5 | Portable, UV protection glasses included |

| Model B | 395 | 5 | 48 | 3.2 | Compact design, built-in timer |

| Model C | 365 | 8 | 30 | 2.0 | Lightweight, user-friendly controls |

| Model D | 400 | 6 | 60 | 4.0 | Fast curing, multiple intensity settings |

| Model E | 385 | 12 | 50 | 3.5 | Versatile applications, energy-efficient |