Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the rapidly evolving world of industrial and commercial printing, the significance of selecting the right UV LED curing device cannot be overstated. As an industry expert, Dr. Emily Thompson, a renowned researcher in photonic technologies, once stated, "The right UV LED curing device can enhance productivity and deliver superior bonding quality, which is crucial for modern applications." With advancements in technology, various options are available, each designed to cater to specific operational needs.

Understanding the unique requirements of your project is essential when choosing a UV LED curing device. Factors such as curing speed, energy consumption, and material compatibility play a pivotal role in making the right decision. As businesses strive to maximize efficiency and output quality, the importance of a tailored approach to selecting a UV LED curing device becomes increasingly clear. In this guide, we will explore key considerations and tips to help you identify the perfect curing solution for your needs, ultimately driving innovation and success in your production processes.

Ultraviolet (UV) LED curing technology has revolutionized the curing process across

various industries, including printing, coatings, and adhesives. This technology utilizes ultraviolet light to dry and

harden materials, offering significant advantages over traditional curing methods. According to a report by

Research and Markets, the UV LED market is projected to grow at a CAGR of 27.5%

from 2021 to 2026, driven by the increasing demand for energy-efficient and environmentally friendly curing

solutions. The shift towards UV LED curing is not only due to its reduced energy consumption but also its ability

to cure instantaneously, which enhances productivity.

The applications of UV LED curing are vast and diverse. In the printing

industry, for instance, UV LED curing allows for faster print speeds, greater adhesion, and improved durability of

printed materials. A study published in the Journal of Coatings Technology and Research highlighted that

UV LED systems can provide up to 50% flexibility compared to conventional

UV curing systems, making them suitable for a wider range of substrates. Additionally, in the field of electronics,

UV LED curing is essential for processes such as potting and encapsulation, where precise and reliable curing is

critical for performance and longevity. As industries continue to embrace sustainability and efficiency,

understanding the unique benefits and applications of UV LED curing technology is essential for making

informed decisions when selecting the right equipment.

When selecting a UV LED curing device, several key factors must be taken into account to ensure it meets your specific needs. First and foremost, consider the application for which you intend to use the device. Different industries may require varied curing speeds, wavelengths, and energy outputs. For instance, a device suitable for printing applications may differ significantly from one used in coatings or adhesives. Understanding the material properties and the curing process involved is crucial to selecting the right device.

Another important factor is the size and configuration of the curing unit. Depending on your workspace and project requirements, you should evaluate whether a handheld, benchtop, or larger automated solution suits your needs. Additionally, consider the safety features, durability, and energy efficiency of the UV LED curing device, as these can impact your operational costs and long-term use. Lastly, look into the ease of use and maintenance, as a user-friendly design can facilitate more efficient workflows and reduce downtime during operations. By carefully assessing these factors, you can make a well-informed decision that enhances your project outcomes.

When selecting a UV LED curing device, understanding the different types available and their specific features is crucial. There are primarily three categories of UV LED curing devices: spot cure systems, flood cure systems, and conveyorized systems. Spot cure systems are typically used for precision applications, allowing for targeted curing on specific areas with high-intensity outputs. According to a recent industry report, these systems are favored in sectors requiring meticulous detail, such as electronics and jewelry, where the curing intensity can significantly affect adhesion and finish quality.

Flood cure systems, on the other hand, provide a broader area of coverage, making them suitable for applications like coating and printing. Their design allows for even exposure across larger surfaces, ensuring that the entire area is uniformly cured. A study done by the UV-LED Consortium indicates that these systems demonstrate high efficiency, with UV light output measured at 50% greater than traditional mercury lamps in similar settings. This efficiency not only enhances productivity but also reduces energy costs and environmental impact.

Lastly, conveyorized systems are ideal for high-volume production lines. They integrate continuous curing processes that significantly boost throughput. With advances in automation, these systems have been reported to offer precision, versatility, and speed, accommodating varying part sizes and types. The Global UV Curing Market Insights report suggests that the market for conveyorized UV LED curing devices is expected to grow at a CAGR of over 15% through 2028, highlighting their increasing demand in manufacturing environments. Understanding these distinctions will aid businesses in making informed decisions tailored to their operational needs.

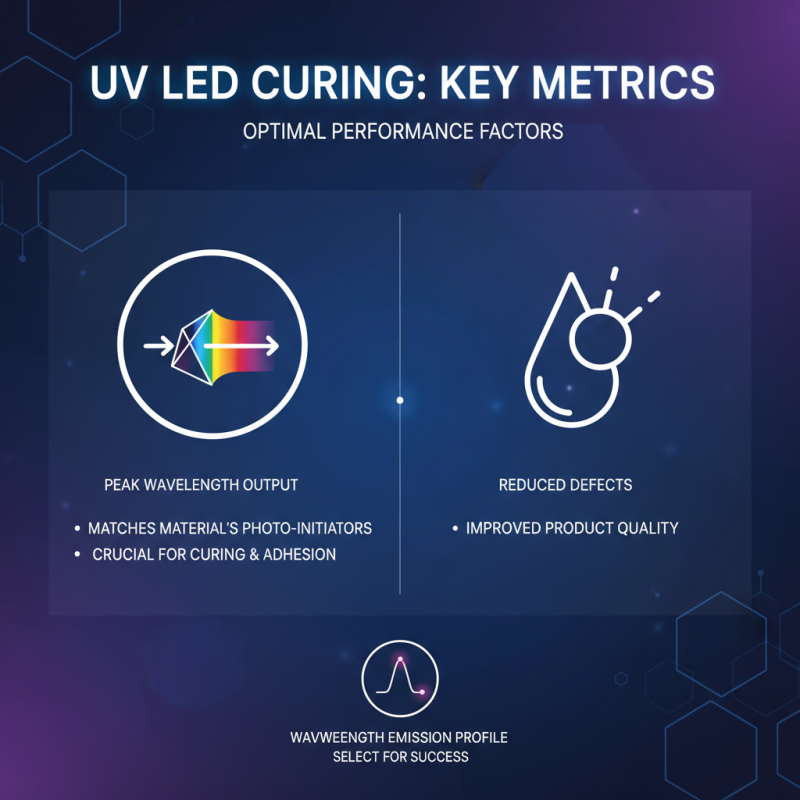

When evaluating performance metrics for UV LED curing devices, there are several key factors to consider. One of the most crucial metrics is the peak wavelength output, which determines how effectively the device can cure specific materials. Devices should be evaluated based on their ability to emit the appropriate wavelengths that match the photo-initiators used in your inks or coatings. This ensures optimal curing and adhesion, reducing the risk of defects in your finished products.

Another important metric is the intensity of the UV light, measured in watts per square meter. Higher intensity often leads to quicker curing times, improving workflow efficiency. However, it’s essential to find a balance; excessively high intensity might lead to overheating or damage to sensitive substrates. Users should always check the intensity levels under actual working conditions, as these can vary significantly from manufacturer specifications.

Tip: When selecting a UV LED curing device, consider conducting a side-by-side comparison of different models to assess their curing speed and performance on your specific materials. Additionally, pay attention to the lifespan of the UV LEDs, as longer-lasting bulbs can reduce long-term operational costs and downtime for replacements.

When considering the acquisition of a UV LED curing device, one of the foremost factors to evaluate is your budget. Curing devices can vary significantly in price depending on their technology, features, and intended use. Establishing a clear budget will help streamline your options and prevent overspending. Factor in not only the initial purchase price but also ongoing maintenance and potential consumables that may be required.

Tips for budgeting include assessing your specific curing needs. Begin by identifying the materials or substrates you will be working with and the volume of production. This understanding will enable you to choose a device that meets your requirements without unnecessary features that can add to the cost. Furthermore, consider potential energy savings offered by UV LED technology, which can lead to lower operational costs over time.

Additionally, explore financing options or leasing arrangements if upfront costs are a concern. Some vendors may offer flexible payment plans that allow businesses to invest in high-quality curing equipment without straining their cash flow. By carefully weighing these considerations, you can make a well-informed decision that aligns with both your operational needs and budget constraints.