Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the printing industry has witnessed a significant transformation driven by advancements in technology, particularly the rise of UV machines for printing. According to a report by Smithers Pira, the global UV printing market is projected to reach $8 billion by 2025, with a compound annual growth rate (CAGR) of 10% from 2020 to 2025. This remarkable growth can be attributed to the efficiency, versatility, and eco-friendliness of UV printing processes. UV machines for printing enable immediate drying, which not only accelerates production but also reduces the need for solvents and chemicals, aligning with the industry's move towards sustainability. As businesses seek to enhance their operational efficiency and meet evolving consumer demands for high-quality print solutions, the adoption of UV technologies becomes increasingly imperative, marking a new era in the industry.

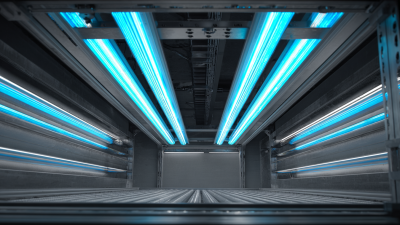

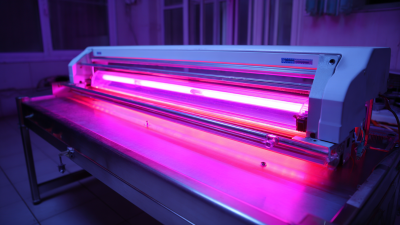

The rise of UV printing technology has significantly transformed the print industry, bringing about a new era of efficiency and precision. Unlike traditional printing methods, UV printing employs ultraviolet light to cure or dry the ink as it is printed. This rapid curing process allows for high-speed production without the lengthy drying times typically associated with conventional inks. As a result, businesses can increase their output and meet tighter deadlines, thereby enhancing overall productivity.

Moreover, the versatility of UV printing is a game changer for various applications. It allows for printing on a diverse range of substrates, including plastics, metals, and even wood, which was often a challenge for earlier printing technologies. This ability opens new avenues for creative designs and multi-dimensional printing, enabling companies to offer unique products that stand out in the market. As UV technology continues to evolve, it promises to further influence industry standards, pushing the boundaries of what is possible in the world of printing.

The advent of UV printing technology has significantly reshaped the landscape of the printing industry, showcasing key advantages that set it apart from traditional methods. One of the most prominent benefits is speed; UV machines utilize ultraviolet light to cure ink instantly, which allows for rapid print production. This efficiency leads to shorter turnaround times, enabling businesses to meet tight deadlines and increasing overall productivity.

In addition to speed, UV machines offer remarkable efficiency in the use of materials. With minimal ink wastage and the ability to print on a diverse range of substrates, including non-porous surfaces, these machines maximize resource utilization. Furthermore, the environmental impact of UV printing is lessened, as the inks are often free from volatile organic compounds (VOCs). This shift towards eco-friendly practices not only aligns with global sustainability goals but also appeals to consumers who increasingly prefer environmentally conscious brands. Thus, the rise of UV machines is not just a technological evolution but a crucial step towards a more efficient and sustainable future in printing.

The UV printing market is experiencing significant growth, driven by advancements in technology and an increasing demand for high-quality prints. According to market research published by Custom Market Insights, the global multifunctional printer market is expected to surge from USD 34.1 billion in 2025 to USD 63.5 billion by 2035, reflecting a robust CAGR of 6.4%. Similarly, the direct-to-film printing market is projected to expand from USD 2.72 billion in 2024 to USD 3.92 billion by 2030. These trends indicate a broader embrace of innovative printing solutions, particularly in the UV sector.

As industries increasingly adopt UV technology due to its efficiency and precision, the demand for UV machines is rising. The printer market is also on the rise, with forecasts showing it will grow from USD 78.9 billion by 2025. This boom highlights how UV printing not only enhances production capabilities but also meets the growing needs for environmentally friendly and fast-drying solutions.

**Tips:** When considering a move to UV printing technology, evaluate your production needs to ensure it aligns with your business goals. Additionally, keep an eye on market trends and statistics to stay ahead of the competition and adapt to changing consumer demands. Investing in UV technology now could position your business for substantial growth in the coming years.

| Year | Global Market Size (USD Billion) | CAGR (%) | Key Applications | Growth Drivers |

|---|---|---|---|---|

| 2020 | 5.5 | 8.2 | Packaging, Signage | Technological advancements, demand for sustainability |

| 2021 | 6.0 | 9.0 | Commercial Printing, Industrial Packaging | Increased e-commerce activities |

| 2022 | 6.8 | 10.5 | Labels, Commercial Print | Shift towards on-demand printing |

| 2023 | 7.5 | 12.0 | Textiles, 3D Printing | Customization and personalization trends |

| 2024 | 8.4 | 15.0 | Decorative Printing, Packaging | Sustainability initiatives |

The rise of UV machines in printing is reshaping industries by enhancing efficiency and precision. In sectors ranging from packaging to promotional materials, these advanced printing technologies have demonstrated their potential through various successful implementations. For instance, a leading packaging company integrated UV printing, significantly reducing production time while achieving vibrant colors and intricate designs. This transformation not only improved the overall quality of their products but also allowed for shorter turnaround times, meeting the increasing demand for customization.

Tips for implementing UV printing effectively: First, assess your current production workflows and identify areas where UV printing can streamline processes. Consider investing in comprehensive training for your team, ensuring they are well-versed in the technology to maximize its capabilities. Additionally, explore collaborations with UV ink suppliers to tailor solutions that meet your specific needs, as choosing the right materials can greatly affect output quality and efficiency.

In the retail sector, a notable case involved a startup using UV printing to produce eye-catching signage and displays. By embracing this technology, they were able to offer unique designs that stood out in a crowded market. The precision of UV machines enabled them to produce intricate details that traditional methods could not achieve, ultimately enhancing customer engagement and boosting sales.

The UV printing industry is on the brink of significant transformation, driven by advancements in technology and increasing market demand. By 2025, the global market for UV curing machines is projected to reach approximately $4.543 billion, with expectations to nearly double to $8.243 billion by 2033. This exponential growth signifies a shift towards more efficient and precise printing solutions that cater to a variety of applications, from packaging to industrial printing.

Emerging trends within the UV printing sector include innovations in 3D printing technologies, particularly notable in Guangdong, where there are the highest concentrations of related enterprises in China. Noteworthy examples include cutting-edge developments from local companies, which have contributed to the evolution of the industry. For instance, pioneering projects such as the "3D printed lion" from a local technology firm showcase the potential of integrating UV printing with creative design.

Such innovations not only enhance production efficiency but also reflect a broader trend towards sustainability and customization in the printing landscape. As these technologies continue to evolve, industry stakeholders must be prepared to adapt and embrace new capabilities that UV printing offers.