Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

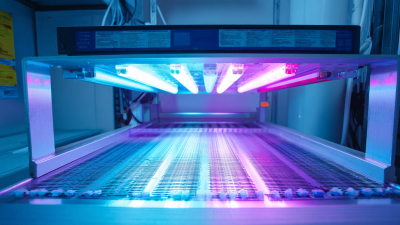

In recent years, the adoption of Ultraviolet Light Systems has surged across various industries, driven by an increasing demand for efficient sterilization and disinfection solutions. According to the U.S. Environmental Protection Agency (EPA), UV light systems can achieve a reduction of up to 99.99% of pathogens in water treatment processes, highlighting their effectiveness. Additionally, a market research report by ResearchAndMarkets.com predicts that the global ultraviolet (UV) disinfection equipment market will reach $6.84 billion by 2027, growing at a CAGR of 17.5%. This boom underscores the importance of maximizing efficiency in Ultraviolet Light Systems to enhance operational effectiveness and reduce costs. In this blog, we will explore essential techniques that businesses can implement to harness the full potential of these systems, ensuring they remain at the forefront of effective disinfection practices.

Ultraviolet (UV) light systems have become essential tools in various fields, from sterilization in healthcare to water purification in environmental management. Understanding the fundamentals of UV light is crucial for leveraging its full potential.

UV light is part of the electromagnetic spectrum, with wavelengths shorter than visible light, which allows it to effectively disrupt the DNA of bacteria and viruses, rendering them inactive.

This unique property makes UV systems particularly valuable in maintaining hygiene and safety in both domestic and industrial settings.

Ultraviolet (UV) light systems have become essential tools in various fields, from sterilization in healthcare to water purification in environmental management. Understanding the fundamentals of UV light is crucial for leveraging its full potential.

UV light is part of the electromagnetic spectrum, with wavelengths shorter than visible light, which allows it to effectively disrupt the DNA of bacteria and viruses, rendering them inactive.

This unique property makes UV systems particularly valuable in maintaining hygiene and safety in both domestic and industrial settings.

The applications of UV light extend beyond disinfection; they also include curing inks in printing processes, enhancing agricultural productivity through pest control, and even promoting chemical reactions in laboratories. Tailoring a UV light system to specific applications requires a good understanding of factors such as intensity, wavelength, and exposure duration. By optimizing these parameters, users can maximize efficiency, ensuring that UV systems operate at peak performance while minimizing energy consumption and increasing their lifespan. Together, these insights underline the importance of mastering the basics of UV light systems to fully unlock their potential across various sectors.

When optimizing ultraviolet (UV) light systems, understanding the law of the inverse square is crucial. This principle dictates that the intensity of germicidal UV light diminishes significantly as the distance from the lamp increases. For effective disinfection, it is essential to position UV lamps at optimal distances to ensure maximum intensity reaches the target surfaces. By carefully calculating the placement, facilities can enhance the system's efficacy, reducing the need for prolonged exposure times and ensuring thorough disinfection.

In addition to distance, coverage area is a critical factor in optimizing UV intensity. Utilizing reflectors or strategically placed UV light units can help in spreading the germicidal rays evenly across larger spaces. This distribution maximizes the effectiveness of the UV systems, ensuring all surfaces receive adequate exposure. Regular maintenance and calibration of the UV lights also play a vital role in sustaining their performance. Monitoring the UV intensity and regularly adjusting the setup can lead to sustained efficiency, ultimately enhancing the overall effectiveness of sterilization processes.

When working with ultraviolet (UV) light systems, the importance of effective maintenance and adherence to safety protocols cannot be overstated. According to a report by the Environmental Protection Agency (EPA), regular maintenance can enhance the efficacy of UV systems by up to 30%. This is crucial because the effectiveness of UV light in disinfection processes diminishes over time due to lamp degradation. Routine checks should include replacing lamps as per the manufacturer's schedule, cleaning quartz sleeves to prevent fouling, and ensuring optimal water flow rates, as these factors collectively influence performance.

Safety is paramount when operating UV systems, as prolonged exposure to UV radiation can pose significant health risks. The American National Standards Institute (ANSI) has outlined stringent safety measures that should be adhered to, such as using appropriate personal protective equipment (PPE) and implementing safety interlocks on UV systems to prevent accidental exposure. Moreover, training staff on the hazards of UV radiation and proper operational procedures can reduce workplace incidents by as much as 50%, as highlighted in a recent study by the Occupational Safety and Health Administration (OSHA). By prioritizing safety and maintenance, organizations can maximize the effectiveness of their UV light systems while protecting their employees and ensuring compliance with industry standards.

Integrating ultraviolet (UV) light systems with other technologies can significantly enhance efficiency in various applications, from water treatment to air purification. According to a report by the American Water Works Association, UV treatment can provide a 99.9% inactivation rate of pathogens when combined with advanced filtration systems. This synergy not only improves the overall disinfection process but also reduces the energy consumption of traditional methods, making it a more sustainable option.

To maximize efficiency, consider the following tips: First, implement a pre-treatment step utilizing activated carbon filters before UV processing. This combination can reduce the turbidity of water, allowing for better UV penetration and effectiveness. Second, explore the integration of UV systems with automated monitoring technologies. These systems ensure optimal light exposure and operational efficiency by adjusting UV intensity based on real-time water quality data. By leveraging these advancements, facilities can minimize maintenance costs and enhance system longevity.

Further embracing innovative technologies can contribute to a more efficient UV system. The integration of UV light with ozone or hydrogen peroxide treatments can create a powerful disinfection trio. Studies indicate that this combination can achieve a higher reduction of resistant microorganisms, making it a compelling choice in industries requiring stringent safety standards, such as food processing and pharmaceuticals. By exploring these avenues, companies can truly maximize their UV light system’s potential.

This chart illustrates the efficiency improvement when integrating ultraviolet light systems with other technologies over five different applications.

Ultraviolet (UV) light systems have gained significant attention for their ability to disinfect and purify across a variety of settings, from hospitals to water treatment facilities. Measuring the effectiveness of these systems is crucial, as different environments can significantly influence UV performance. Factors such as the intensity of the UV light, the duration of exposure, and the nature of the surfaces or substances being treated all play critical roles in determining how effectively pathogens are eliminated.

In clinical settings, for instance, the workflow and occupancy levels can affect UV light reach and efficacy. Regular monitoring using specific UV sensors can provide valuable data on the intensity and distribution of UV light, helping to adjust the technology for optimal performance. Meanwhile, in industrial applications, the presence of particulates and varying water turbidity can hinder UV effectiveness. Testing under these conditions is essential to ensure that the systems are achieving the desired disinfection levels, leading to better health outcomes and operational efficiency. Every environment presents unique challenges, and a tailored approach to measuring effectiveness will ensure that UV light systems are utilized to their full potential.

| Environment Type | UV Light System Type | Effectiveness (%) | Duration (hrs) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Hospital Cleanroom | Medium Pressure Mercury | 95 | 24 | 6 |

| Food Production Facility | Low-Pressure Mercury | 90 | 12 | 4 |

| Aquarium | UV-C Light | 85 | 10 | 3 |

| Office Buildings | UV-C LED | 80 | 8 | 12 |

| Public Transport | Portable UV Systems | 75 | 5 | 2 |