Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the use of UV curing technologies has surged, with the global UV curing market projected to reach approximately $5 billion by 2027, growing at a compound annual growth rate (CAGR) of over 11% (Grand View Research). Central to this technology is the UV Curing Flood Lamp, a critical tool for achieving rapid and efficient curing in various applications, including coatings, inks, and adhesives. As industries strive for higher productivity and quality, optimizing the performance of UV Curing Flood Lamps has become essential. Experts agree that proper setup and usage can significantly enhance curing efficiency, leading to reduced production times and improved finish quality. This article will delve into seven expert tips that can help users harness the full potential of their UV Curing Flood Lamps, ensuring they remain competitive in an increasingly demanding marketplace.

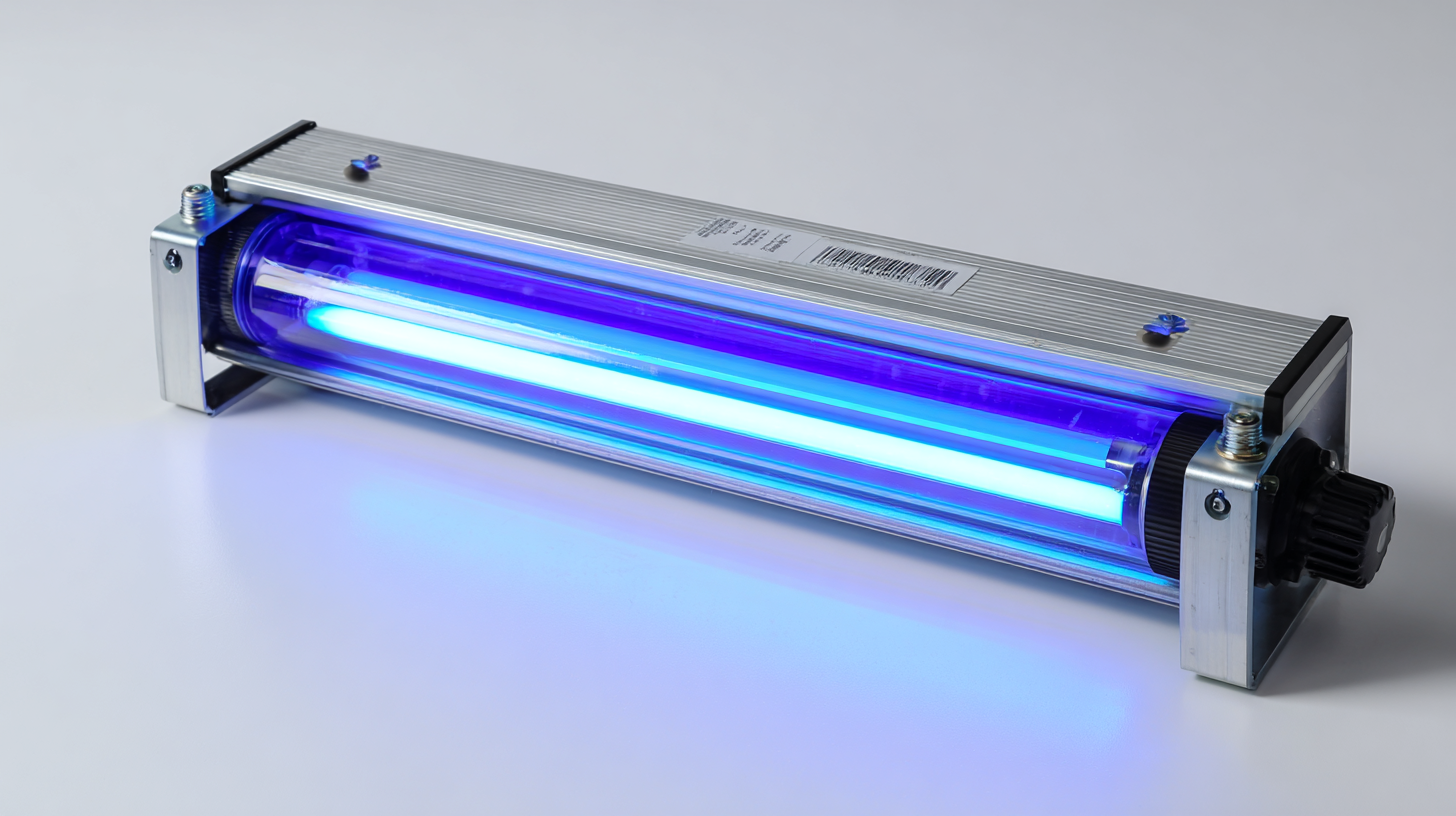

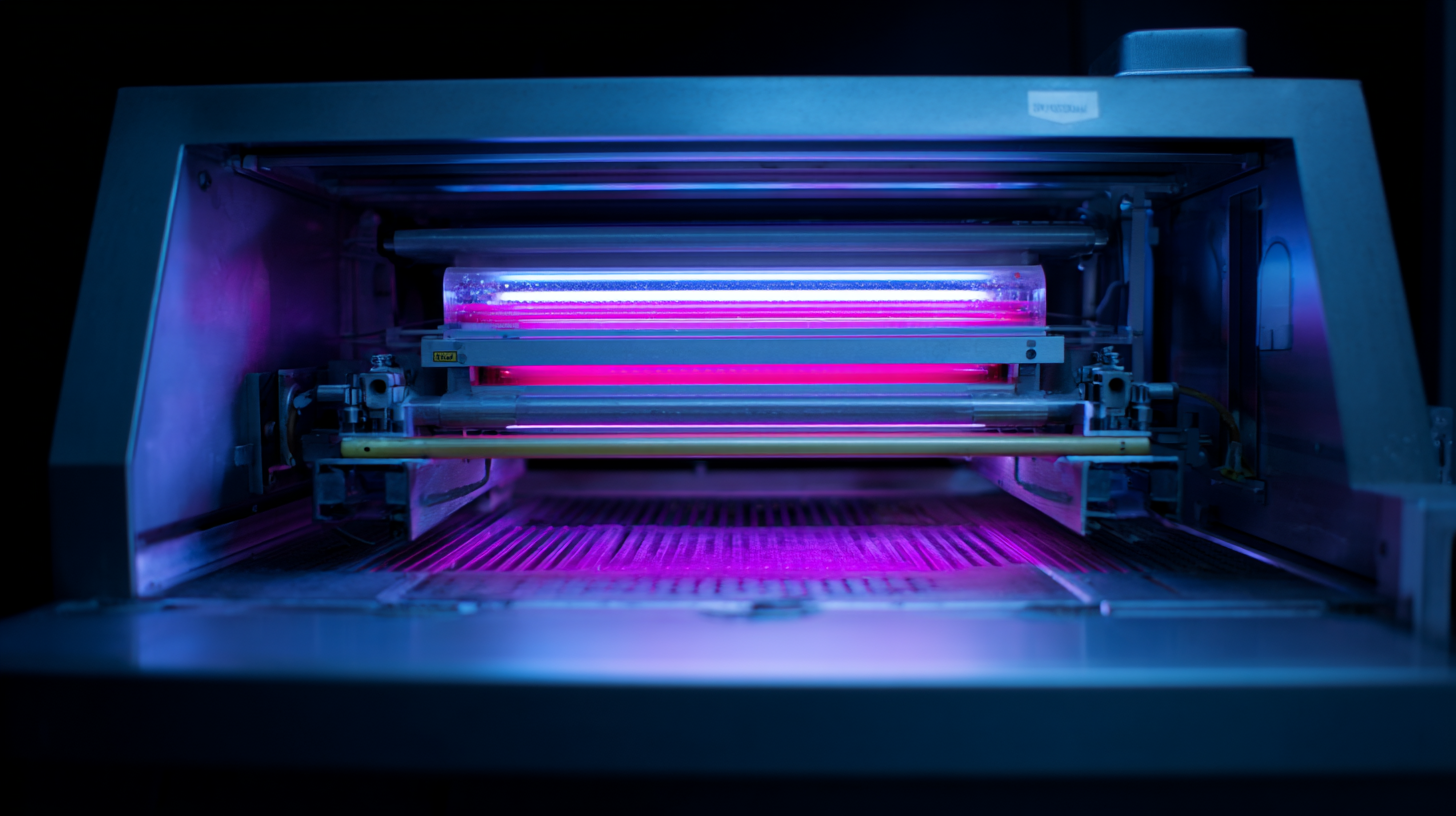

UV curing is a process that utilizes ultraviolet light to initiate chemical reactions, leading to the rapid curing of materials. At the heart of this technology are UV curing flood lamps, which emit broad-spectrum UV light across large areas to ensure even and effective curing. This method is widely employed in various industries, including printing, automotive, and electronics, for its ability to enhance production efficiency and improve product durability.

Flood lamps are designed to cover extensive surfaces and are particularly valuable in applications where consistent curing is critical. By delivering uniform UV light, these lamps minimize the risk of uneven curing, which can lead to defects in the final product. Understanding the interaction between the lamp’s output and the materials being cured is essential for optimizing the curing process, thereby ensuring maximum adhesion and surface hardness. The right choice of lamp, along with proper positioning and exposure time, can significantly impact the longevity and quality of the cured surface, making it a crucial aspect of production in many sectors.

| Tip | Description | Benefits |

|---|---|---|

| 1. Optimize Lamp Position | Ensure that the flood lamp is positioned at an optimal angle to achieve maximum exposure. | Increased curing speed and efficiency. |

| 2. Regular Maintenance | Perform regular cleaning and maintenance on the lamp. | Prevention of downtime and consistent performance. |

| 3. Monitor Power Settings | Adjust the power settings based on the material being cured. | Optimal energy usage and reduced costs. |

| 4. Use the Right Coatings | Choose UV coatings that are compatible with the UV flood lamp. | Improved adhesion and enhanced finish quality. |

| 5. Control Environment | Maintain optimal temperature and humidity levels for curing. | Consistent curing results and reduced defects. |

| 6. Train Your Team | Educate your staff on proper lamp operation and safety. | Reduced errors and improved safety measures. |

| 7. Experiment with Timing | Adjust curing times based on different materials and lamp settings. | Enhanced product quality and efficiency in production. |

When it comes to maximizing the efficiency of UV curing flood lamps, understanding the key factors that influence their performance is essential. The UV curing technology has gained significant traction, projected to reach a market size of USD 23.47 billion by 2025. This remarkable growth underscores the increasing adoption of UV curing in various industries, from printing to coatings and adhesives. One of the primary factors that impacts the efficiency of UV flood lamps is the intensity of the ultraviolet light emitted. Higher intensity results in faster curing times, which is vital in high-volume production settings.

Another crucial factor is the wavelength of the UV light, as different materials react to specific wavelengths. Optimizing the wavelength can enhance the bonding process when using UV adhesives, particularly in device assembly where precise adhesion is paramount. As companies increasingly turn to UV curing solutions to streamline their processes, understanding these key variables can help maximize the effectiveness of their curing systems and ultimately improve product quality and production efficiency. This strategic approach is increasingly relevant in an industry focused on innovation and sustainability, where efficiency translates into competitive advantage.

When utilizing UV curing flood lamps, selecting the optimal wavelength and intensity is crucial to achieving maximum efficiency. Research from the UV & EB Lamps Association indicates that different materials respond uniquely to various wavelengths, typically ranging from 320 to 420 nm. For instance, UV adhesives and coatings often cure most efficiently at wavelengths between 365 nm and 395 nm. By consulting product specifications and conducting preliminary tests, one can pinpoint the ideal wavelength that meets application demands and enhances curing speed.

In addition to wavelength, light intensity plays a vital role in the curing process. Data shows that increasing intensity can reduce curing times and lead to improved hardness and adhesion of cured products. For a successful setup, aim for an intensity measured in watts per square meter (W/m²) that aligns with the manufacturer’s recommendations. Many experts suggest starting at 200-300 W/m² and making adjustments based on real-time results during the curing process.

Moreover, adjusting the distance between the UV lamp and the substrate can help fine-tune intensity. A closer distance will increase intensity but may lead to overheating; conversely, too far may result in insufficient curing. By iterating on these settings, manufacturers can achieve the optimal balance necessary for their unique applications, thereby maximizing the efficiency of their UV curing processes.

Maintaining UV curing equipment is crucial for optimizing performance and extending its lifespan. According to a report by the RadTech International organization, regular maintenance can enhance equipment efficiency by up to 30%. This efficiency boost can lead to significant cost savings over time, as well-maintained systems require less energy and incur lower repair costs.

Adopting best practices such as regularly cleaning the quartz sleeve, checking bulb performance, and ensuring proper ventilation can directly impact the effectiveness and durability of UV curing lamps.

Adopting best practices such as regularly cleaning the quartz sleeve, checking bulb performance, and ensuring proper ventilation can directly impact the effectiveness and durability of UV curing lamps.

Furthermore, tracking the usage cycles of UV lamps is essential. The American Coatings Association highlights that the lifespan of UV lamps generally ranges from 1,000 to 2,000 hours, depending on brand and model. Having a structured maintenance schedule based on these hours can help in timely replacements and prevent unexpected downtimes. Additionally, using protective covers while the lamps are not in use can minimize the dust build-up, further preserving their output and longevity. Implementing these maintenance strategies not only secures optimal performance but also upholds safety standards while ensuring compliance with industry regulations.

When evaluating the performance of UV curing flood lamps compared to traditional curing methods, the advantages become clear. Industry reports indicate that UV curing can reduce processing times by up to 50% compared to thermal curing, significantly increasing production efficiency. Additionally, UV-curing systems typically require less energy, translating to lower operational costs. For instance, studies have shown that UV systems consume roughly 20%-30% less energy than conventional heating methods, making them not only faster but also more economical.

To maximize the efficiency of your UV curing flood lamp, consider adjusting the distance between the lamp and the substrate. A distance of around 10-12 inches can optimize exposure while minimizing glare and excessive heat. Additionally, ensure that your lamp's intensity is appropriate for the type of inks or coatings being used, as this can greatly affect curing time and finish quality. Implementing a regular maintenance schedule for your UV system to clean and replace bulbs will also ensure consistent output and longevity.

In a comparative analysis, UV curing flood lamps often outperform LED and conventional methods in terms of curing speed and adhesion quality. Recent performance data highlights that UV-cured inks exhibit adhesion strengths that are 30% superior to those cured with heat. This robustness underscores the importance of selecting the right curing technology for your specific application to enhance productivity and quality.