Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

LED curing lamps have revolutionized various industries, especially in dental and nail care. These lamps are designed to emit specific wavelengths of light, curing materials quickly and efficiently. According to a report by Grand View Research, the global LED curing equipment market is expected to reach $3.3 billion by 2025, indicating significant growth and adoption.

One of the most remarkable features of LED curing lamps is their energy efficiency. They consume less power compared to traditional curing devices. However, this efficiency comes with challenges. Not all lamps effectively cure every type of material. Some users may experience mixed results, which can lead to frustration and waste.

Furthermore, while LED curing lamps have a longer lifespan, they can be costly to purchase upfront. Many small businesses may hesitate to invest in this technology. Understanding the full capabilities and limitations of LED curing lamps is crucial. Their proper use can enhance workflow and product quality, but improper application can result in unsatisfactory outcomes. As the industry evolves, attention to these factors remains vital.

LED curing lamps are specialized devices used for quick drying and hardening materials. They primarily use light-emitting diodes (LEDs) to emit specific wavelengths. This targeted light interacts with photoinitiators in materials like adhesives and inks. As the light shines, these materials undergo a chemical reaction, transforming from a liquid state into a solid form.

These lamps are efficient and versatile. They save time in processes like woodworking and nail salons. However, not all materials cure well under LED lamps. Some prefer traditional UV lamps, which can lead to selection challenges. Additionally, the initial cost of LED curing lamps can be higher than other options. Users must weigh the upfront investment against long-term benefits, such as lower energy costs and longer lifespan.

The technology is constantly evolving. Early models may provide inconsistent results. Over time, manufacturers improve their designs, yet some lamps still fall short of expectations. Understanding these nuances is essential for anyone considering LED curing lamps.

LED curing lamps are crucial in various industries, particularly in dentistry and materials science. These devices operate through a straightforward yet effective mechanism. They emit light in specific wavelengths, which trigger photochemical reactions in light-sensitive materials. This curing process solidifies or hardens substances like dental resins and coatings, promoting efficient workflow.

The principles behind LED curing lamps revolve around light intensity and wavelength. Typically, they use a narrow spectrum of blue light, around 400 to 500 nanometers. This targeted approach ensures that the curing process is both rapid and energy-efficient. However, not all materials respond well to this light. In some cases, finding the right lamp for specific materials can be challenging.

It’s important to consider exposure time. Insufficient light can lead to incomplete curing. On the other hand, excessive exposure may cause overheating or compromise materials. Thus, users must strike a balance. Testing different settings and materials is essential. Real-world applications often reveal variances that theory alone cannot predict. This trial-and-error process is vital for achieving optimal results when using LED curing lamps.

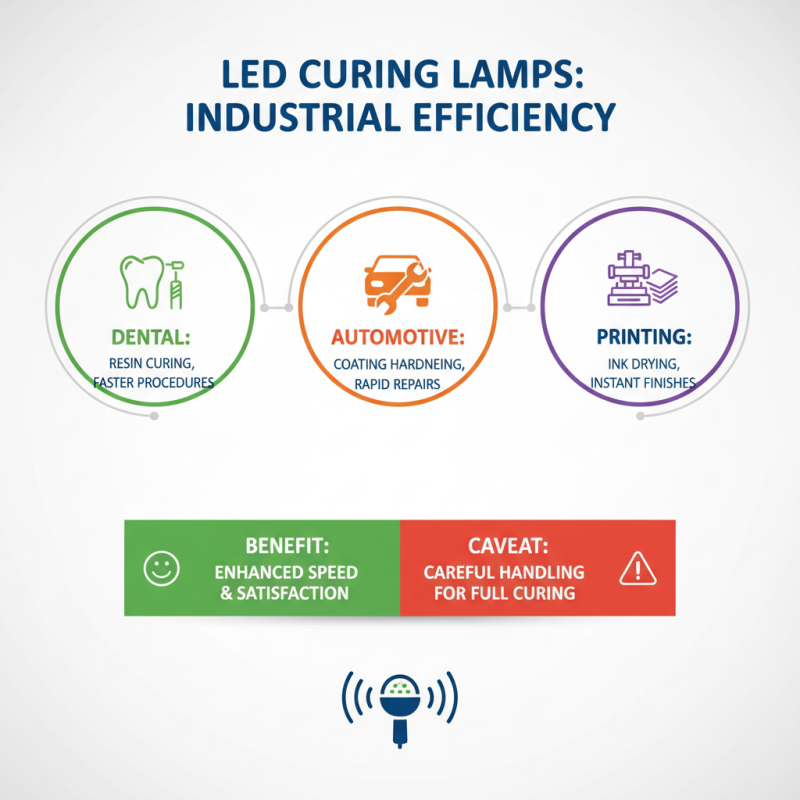

LED curing lamps have gained popularity across various industries due to their efficiency and effectiveness. These lamps utilize light-emitting diodes to cure or harden materials rapidly. They are particularly beneficial in the dental, automotive, and printing sectors. In dental practices, artists use these lamps to cure dental resins, allowing for quicker procedures. This speed can enhance patient satisfaction but may require careful handling. If not used correctly, the materials may not cure fully.

In the automotive industry, LED curing lamps help to accelerate paint drying. Body shops rely on them to improve turnaround times. However, while they offer faster results, there's a risk. If the painted surfaces are too thick, uneven curing can occur. This inconsistency can affect the final appearance and durability of the finish.

The printing industry also benefits from LED technology. It offers instant drying, which allows for faster production. It encourages creativity, enabling designers to experiment without long waits. Yet, there are concerns about the initial investment in this technology. Companies must weigh the cost against potential increases in efficiency. Implementing new systems often presents challenges, necessitating training and adjustments.

LED curing lamps have gained popularity in various fields, notably in dentistry and nail care. These lamps provide a fast and efficient way to cure materials. In dental practices, they are primarily used for curing composite resins. The strong light emitted from LED lamps activates photoinitiators in the resin, leading to a quick hardening process. This allows dentists to complete procedures more efficiently, reducing the time patients spend in the chair.

In nail care, LED lamps play a crucial role in gel manicure applications. Nail technicians use these lamps to cure gel polish, resulting in a durable finish that can last weeks. The UV-free light is a significant advantage, minimizing potential skin damage. However, not all gel products work with LED lamps. This inconsistency can lead to confusion for both technicians and clients. A misunderstanding in the curing process can result in chips and peeling. Continuous education is necessary for nail professionals to keep up with product developments and ensure the best results for their clients.

LED curing technology is rapidly evolving. Recent reports indicate significant advancements that promise faster and more efficient curing processes. These innovations are central to industries like dentistry and manufacturing. The predicted growth rate for LED curing systems is expected to reach 15% annually over the next five years, according to industry analyses.

Key developments include improved wavelength specificity. New LED lamps target specific resin types for optimal curing. This not only enhances quality but may reduce errors in processes. Manufacturers are focusing on designs that minimize energy consumption, making them more sustainable and cost-effective.

Tips: Always compare wavelengths when selecting curing lamps. Specificity in wavelength ensures better results.

Emerging smart technologies are also on the horizon. Some LED curing systems now feature connectivity with mobile applications. This allows real-time monitoring and automation, thus reducing human error. Yet, with all progress comes the challenge of integration. Professionals may need extra training to adapt to these innovations effectively.

Tips: Consider ongoing training programs. Staying updated enhances user confidence in new technologies.