Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

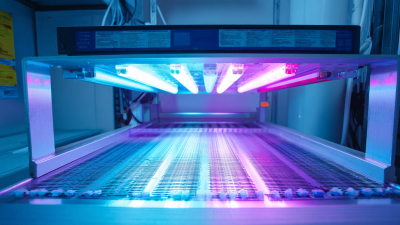

In recent years, the landscape of manufacturing and processing has been significantly altered by advancements in technology, particularly through the rise of UV LED curing equipment. As industries seek faster and more efficient production methods, the global UV curing market, valued at approximately $3.2 billion in 2020, is projected to reach $5.0 billion by 2026, growing at a compound annual growth rate (CAGR) of around 8.5%. Several factors are driving this trend, including increased awareness of environmental sustainability and the demand for high-quality finishes.

UV LED curing equipment is not only enabling manufacturers to reduce energy consumption but also improving productivity and product durability across various sectors. This blog will explore seven innovative trends in UV LED curing equipment that are transforming industries, shedding light on the reasons behind their rapid adoption and the future potential they hold.

The rise of UV LED curing technology marks a significant transformation in manufacturing processes across various industries. Unlike traditional curing methods, UV LED technology offers faster curing times and lower energy consumption, making it an attractive option for manufacturers looking to enhance efficiency. This advancement allows for immediate handling of goods after curing, reducing bottlenecks in production lines. As a result, businesses are increasingly adopting this technology to meet growing demands while simultaneously lowering operational costs.

Moreover, the use of UV LED curing technology supports sustainability efforts by producing less heat and reducing volatile organic compounds (VOCs) emitted during the curing process. As industries strive to meet stricter environmental regulations, this technology not only helps companies achieve compliance but also improves their overall environmental footprint. The trend is evident across sectors such as automotive, electronics, and printing, where manufacturers can leverage UV LED curing for improved product quality and enhanced performance. This innovation is set to redefine manufacturing standards, fostering a new era of efficiency and sustainability.

The rise of UV LED curing equipment is significantly revolutionizing production lines across various industries, primarily due to its enhanced energy efficiency. According to a recent report by Research and Markets, the global UV LED market is projected to grow at a CAGR of 10.8% from 2021 to 2026, driven by the increasing demand for more sustainable manufacturing processes. Unlike traditional curing methods that rely on high-energy mercury lamps, UV LED systems consume up to 80% less energy, making them an environmentally friendly alternative while reducing operational costs.

Moreover, the quick curing times associated with UV LED technology are transforming production capabilities. A study from the European Coatings Journal highlighted that manufacturers can reduce their cycle times by up to 50% when utilizing UV LED systems, resulting in faster turnaround on production lines. With less energy consumption and improved efficiency, companies are not only meeting the growing demand for faster product delivery but also contributing to sustainability goals that are increasingly pivotal in today’s market landscape. As industries adapt to these innovative solutions, the implications for resource conservation and enhanced productivity are game-changing.

The UV curing system market is projected to grow significantly, with an expected size of USD 7.89 billion and a CAGR of 6.69% by 2034. This growth underscores the versatility of UV LED technology across various industries, from automotive to biomedical applications. UV LEDs are transforming production processes by offering rapid curing times and superior energy efficiency, making them a favorable choice for manufacturers seeking to optimize their operations.

One notable application is in the field of mycelium-based composites, where UV LED curing allows for the rapid hardening of these sustainable materials, promoting eco-friendly innovations. Similarly, in the realm of medical light therapy, UV LEDs are gaining traction for their ability to promote healing while minimizing patient exposure to harmful substances. As industries increasingly recognize the potential of UV LED technology, adopting it can substantially enhance productivity and sustainability.

Tips:

The shift toward eco-friendly curing processes is gaining momentum, particularly within industries utilizing UV LED technology. Traditional curing methods often involve harmful chemicals and high energy consumption, contributing to a significant environmental footprint. In contrast, UV LED curing equipment offers a cleaner alternative, utilizing less energy and generating fewer emissions. This technology not only reduces environmental impact but also enhances workplace safety by minimizing exposure to hazardous substances typically found in solvent-based cures.

The integration of automation in UV LED curing equipment is revolutionizing smart curing solutions across various industries. As manufacturing processes continue to evolve, the demand for efficiency and precision has led to the development of advanced curing systems that leverage automated technologies. These systems not only minimize manual intervention but also enhance throughput by allowing for continuous production cycles. With smart sensors and real-time monitoring, manufacturers can ensure consistent quality while reducing waste and energy consumption, significantly optimizing their operational workflow.

Moreover, the adoption of Industry 4.0 principles has paved the way for intelligent UV LED curing systems that communicate seamlessly with other machinery and software platforms. This connectivity enables predictive maintenance and data-driven decision-making, allowing businesses to respond quickly to changes in production demands. As a result, manufacturers can achieve greater flexibility and adapt their processes without compromising on curing quality. The fusion of automation with UV LED curing equipment is setting a new standard for operational excellence, ensuring that industries not only meet the challenges of today but are also well-prepared for future growth.