Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

The 2025 China Import and Export Fair, known as the Canton Fair, serves as a significant platform for showcasing cutting-edge technologies and innovations across various industries.

The 2025 China Import and Export Fair, known as the Canton Fair, serves as a significant platform for showcasing cutting-edge technologies and innovations across various industries.

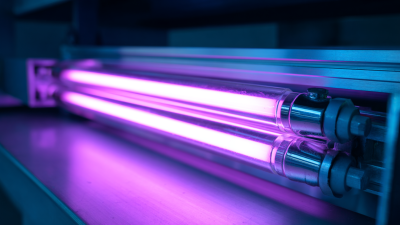

Among the remarkable advancements set to be highlighted at this prestigious event is the development of Led UV Curing Light technologies. These innovative light sources have revolutionized the curing process in sectors such as printing, coatings, and adhesives, offering enhanced efficiency, speed, and environmental benefits compared to traditional curing methods.

As manufacturers and consumers increasingly prioritize sustainability and performance, Led UV Curing Light technologies are poised to capture attention at the fair. This exploration will delve into the implications of these technologies, evaluating their impact on the market landscape and fostering discussions around their future applications in industrial settings.

Through comprehensive analyses and industry insights, the potential of Led UV Curing Light will be scrutinized, reflecting its pivotal role in shaping the future of manufacturing and production at this international trade fair.

The evolution of LED UV curing light technologies in recent years has been marked by significant advancements and increasing adoption across various industries. As the UV LED market is projected to grow at a compound annual growth rate of 21.27% from 2024 to 2032, it is clear that industries are recognizing the benefits of ultraviolet light-emitting diodes for applications such as advanced disinfection and curing processes. These innovations not only enhance efficiency but also promote eco-friendliness, making UV curing a sustainable choice in manufacturing and printing.

Tips: When considering the implementation of LED UV curing technologies, it's crucial to evaluate the specific needs of your operations. Ensure you choose high-quality, compatible materials for optimal performance. Additionally, staying updated on the latest advancements can provide you with a competitive edge in your industry.

Moreover, the shift from conventional mercury lamps to deep-UV LEDs represents a pivotal transition in the market. The improved lifespan and energy efficiency of these LEDs have positioned them as reliable alternatives, especially in applications like polymer curing and even in the auto body industry, where faster cycle times are essential. Embracing this technology can lead to significant cost savings and increased production capabilities.

| Year | Technology Type | Wavelength Range (nm) | Market Adoption Rate (%) | Application Areas |

|---|---|---|---|---|

| 2019 | Standard LED UV | 365 | 15 | Printing, Coating |

| 2020 | High-Performance LED UV | 395 | 25 | Adhesives, Inks |

| 2021 | Broadband LED UV | 350-420 | 40 | Textiles, Electronics |

| 2022 | Nano-Optimized LED UV | 385 | 55 | Furniture, Flooring |

| 2023 | Smart LED UV | 360-410 | 70 | Automotive, Medical |

| 2024 | Eco-Friendly LED UV | 365-405 | 80 | Sustainable Products |

| 2025 | AI-Integrated LED UV | 350-410 | 90 | Robotics, Aerospace |

The implementation of LED UV curing light technologies is transforming various industries by enhancing efficiency and sustainability. In the printing sector, for instance, the global market for LED UV curing is expected to reach approximately $3.6 billion by 2025, driven by the growing demand for faster drying times and improved print quality. Reports indicate that LED curing systems consume up to 70% less energy compared to traditional UV lamps, reducing operational costs while enabling companies to meet tight production schedules.

In the coatings and adhesives industry, LED UV curing is gaining traction due to its ability to cure materials rapidly without emitting harmful solvents. The market for LED UV-cured coatings is projected to witness a CAGR of 12.6% from 2020 to 2027, reflecting a shift towards environmentally friendly practices. Industries are increasingly adopting these technologies to adhere to stringent regulations and customer preferences for low-VOC (volatile organic compounds) products. As manufacturers leverage LED UV curing technologies, the versatility and effectiveness of these systems are anticipated to drive further innovation and growth across diverse sectors, including automotive, electronics, and biodegradables.

The benefits of LED UV curing light technologies over traditional curing methods are becoming increasingly apparent, especially as industries seek more efficient and sustainable solutions. One of the key advantages is the rapid curing time. LED UV curing can significantly reduce production cycles, allowing for faster turnaround in manufacturing processes. Additionally, LED lights emit lower levels of heat, which minimizes the risk of warping or damage to sensitive substrates, making it an ideal choice for various materials.

Another significant benefit lies in the energy efficiency of LED UV systems. Compared to conventional UV curing, which often requires substantial energy inputs, LED technology offers a more sustainable approach. The longer lifespan and reduced energy consumption of LED lights contribute to lower operational costs. Furthermore, advancements in UV LED resin formulations are enabling the creation of innovative materials that boast enhanced properties, such as wear resistance and antibacterial features. This shift towards LED UV curing not only addresses environmental concerns but also enhances the overall quality and performance of finished products across multiple sectors.

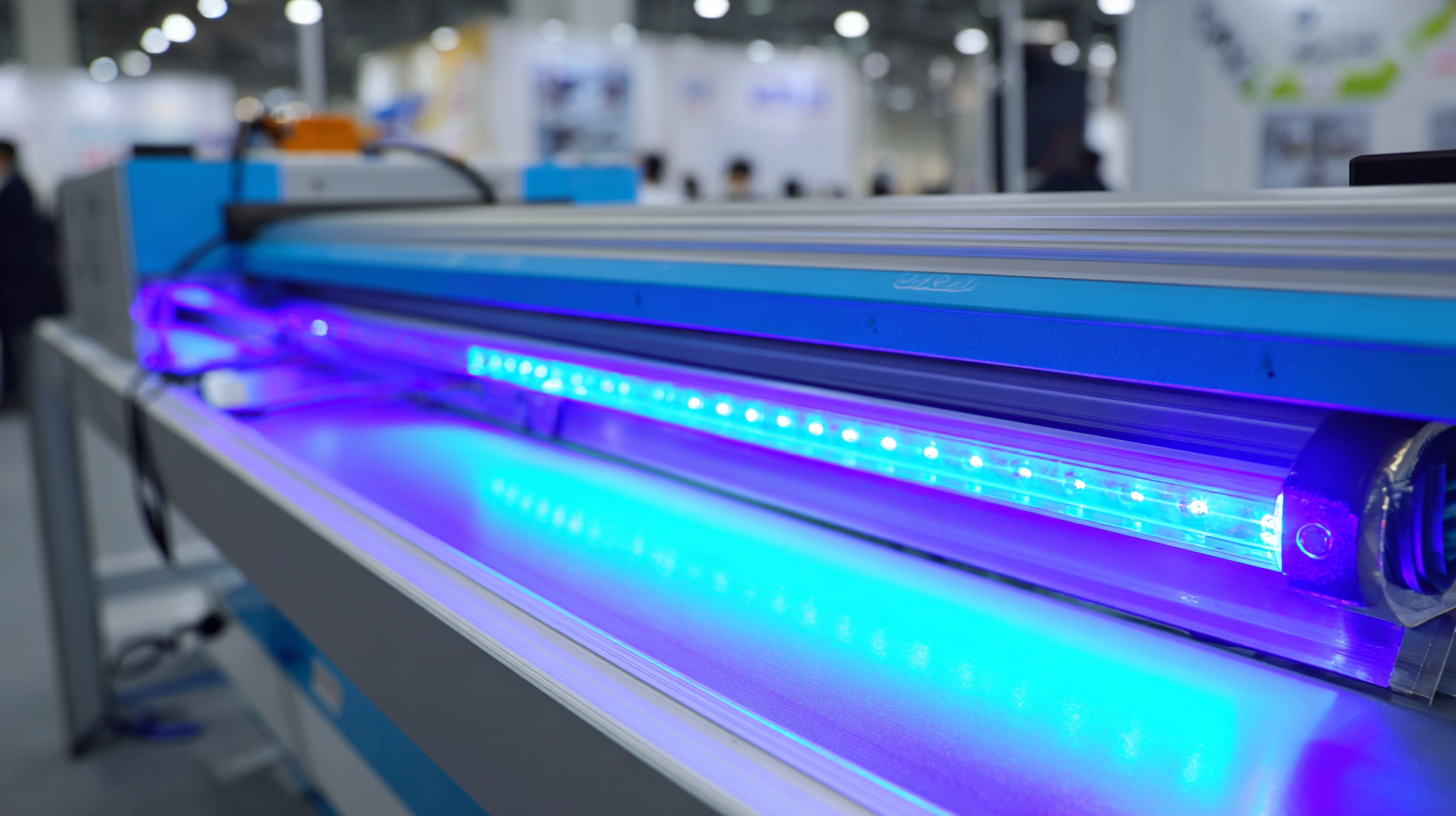

The 2025 China Import and Export Fair serves as a prominent platform for showcasing innovative products, with a particular emphasis on LED UV curing light technologies. This revolutionary advancement in curing processes is garnering significant attention from manufacturers and entrepreneurs alike. The fair presents a unique opportunity for exhibitors to demonstrate the efficiency and effectiveness of these technologies in various applications, including printing, electronics, and automotive industries.

Among the standout innovations, products utilizing LED UV light not only enhance production speed but also contribute to sustainability by reducing energy consumption and waste. Attendees can expect to see live demonstrations of these cutting-edge tools, highlighting their versatility and potential for improving workflow. Manufacturers are eager to engage with international buyers, illustrating how these advanced curing solutions can transform their operations and product offerings. The fair’s focus on innovation positions it as a critical event for industry professionals seeking to stay ahead of the curve in an ever-evolving market.

The rapid evolution of LED UV curing technologies is shaping the future of various industries, particularly in printing, coatings, and adhesives. As businesses increasingly seek more efficient and environmentally-friendly solutions, LED UV curing systems gain popularity due to their lower energy consumption and reduced heat output compared to traditional curing methods. Innovations in material formulations also continue to enhance the effectiveness of these technologies, allowing for faster curing times and improved adhesion properties.

At the 2025 China Import and Export Fair, industry leaders will showcase the latest advancements in LED UV curing technologies. These developments are set to usher in a new era of customization and application versatility. For instance, new spectral output LEDs are being engineered to accommodate a broader range of substrates, which broadens their utility in diverse sectors, from automotive to electronics. Additionally, the integration of smart technologies, such as IoT capabilities, allows for real-time monitoring and optimization of the curing process, further enhancing efficiency and product quality.

As LED UV curing technology continues to evolve, its integration into production lines will significantly impact the manufacturing landscape. The trend towards sustainability remains a driving force, encouraging innovations that minimize waste and energy usage. The future of LED UV curing promises not only operational advancements but also a commitment to greener practices, marking an exciting chapter for manufacturers and consumers alike in the global marketplace.