Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right UV LED light lamp can be challenging. With a variety of options on the market, making an informed decision is crucial. An industry expert, Dr. Emily Hart, once said, “The right UV LED light lamp can transform your workspace." This statement highlights the importance of selecting a lamp that suits your specific needs.

When considering a UV LED light lamp, think about its application. Whether for curing nails, resin, or other tasks, the right lamp will enhance your results. Some lamps may offer quick curing but could bear drawbacks like uneven coverage. Understanding these trade-offs is essential for a wise choice.

Many users rush into their purchase decisions without proper research. They may overlook critical features such as wavelength and durability. Emotional satisfaction from instant results often clouds judgment. Reflecting on your true needs can lead you to the best UV LED light lamp tailored for your projects. Choose carefully; the lamp you select today can greatly impact your future work.

UV LED light technology offers numerous benefits. These lights emit ultraviolet light while using less energy than traditional options. They are more environmentally friendly, making them popular in various applications. From curing nails to disinfection, UV LED lights are versatile. They can help reduce costs and increase efficiency—however, they aren’t perfect.

When choosing a UV LED lamp, consider the wavelength. Different purposes require different wavelengths. For example, nail curing typically uses 365 nm to 405 nm. Disinfection may need shorter wavelengths around 254 nm. Understanding these differences is crucial for optimal results.

**Tip:** Always think about the lamp’s intensity. Higher intensity means faster results, but may also cause overheating. Monitor the lamp’s performance to avoid mishaps.

Also, reflect on the size and design. A larger lamp may not fit in small spaces. Think about where you will use it. Compact models are available but may compromise intensity. Choose wisely to suit your needs. Each choice involves priorities and trade-offs.

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Wavelength | Common wavelengths for UV LED lights range from 365nm to 405nm. | Different applications such as curing, sterilization, and inspection require specific wavelengths. | Ensure the wavelength aligns with your intended use. |

| Power Output | Measured in watts; influences intensity and speed of curing processes. | Higher power produces faster results and stronger efficacy. | Consider your project's size and requirements for adequate power. |

| Cooling System | Includes fans or heat sinks to prevent overheating during operation. | Extends the lifespan of the lamp and enhances performance. | Evaluate the operating environment for effective heat management. |

| Life Span | Typically ranges from 10,000 to 50,000 hours, depending on use. | Long lifespan results in cost savings and reduced maintenance. | Factor in your usage frequency to predict replacement needs. |

| Features | Look for features like adjustable intensity, timers, and remote control. | Enhances versatility and user experience for various applications. | Determine which features are essential for your work tasks. |

When selecting a UV LED light lamp, key features impact performance significantly. Start with the wavelength. Different tasks require specific wavelengths for effectiveness. Think about your actual needs. For nail curing, a wavelength around UV 400nm works best. But for disinfection, a narrower range may be needed. The lamp’s design can also matter. A compact model might be easier to use but could lack power.

Next, consider the light intensity. Higher intensity means quicker curing or disinfection times. However, more potent lamps can generate heat. This factor matters for skin safety. Look at the cooling mechanisms included. Some lamps have fans or heat vents to combat this. Assess the durability, too. Reliable lights can last for many hours. Check for features like timer settings. These can enhance user experience and improve safety.

Lastly, think about portability. A portable lamp adds a layer of convenience. But some lightweight options compromise power. Carefully weigh these details based on your priorities. Not everyone needs the top-of-the-line model. Sometimes, a more basic choice fits better. Identifying these needs is essential for making a decision.

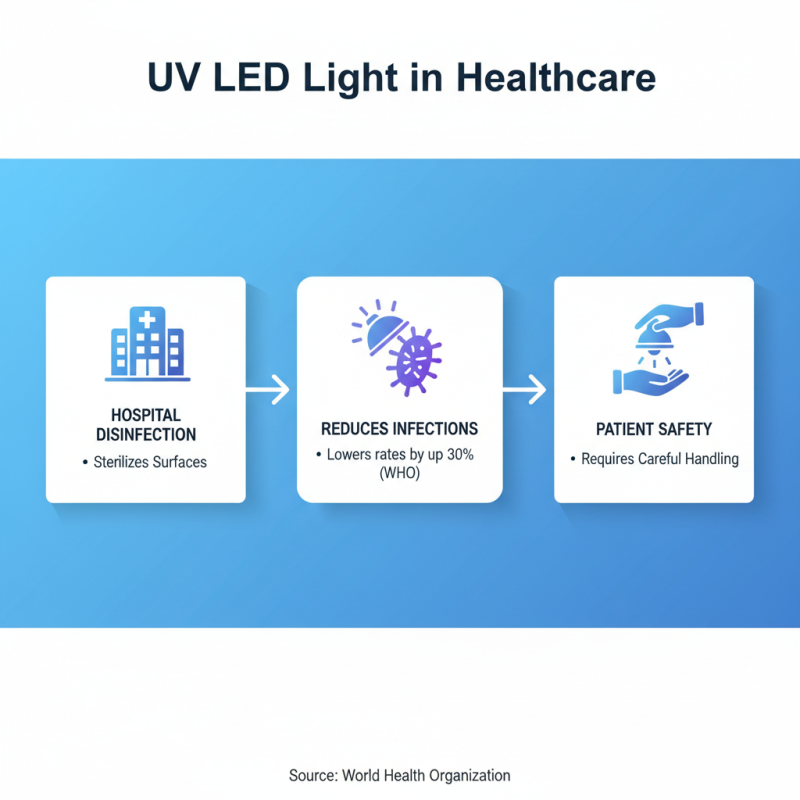

UV LED light lamps have become essential in various industries due to their versatile applications. In the healthcare sector, these lamps are used for disinfection. Hospitals use UV light to sterilize surfaces, which reduces hospital-acquired infections. According to a report by the World Health Organization, UV disinfection can lower infection rates by up to 30%. This is significant for patient safety but requires careful handling to ensure effective results.

In the printing industry, UV LED light lamps cure inks quickly, which enhances productivity. They allow for immediate product handling after printing. A recent study indicated that using UV lamps can increase production speed by 50%. However, there are challenges. Not all materials can withstand UV light, which necessitates testing. Not every printer can also adapt easily to UV technology.

Another crucial application is in the food industry. UV systems are employed for surface sterilization of packaging. This can extend shelf life and reduce foodborne illnesses. The FDA has noted a rise in UV systems in food safety practices. Still, the effectiveness of these systems heavily relies on correct usage and maintenance. Each application poses unique challenges that require careful consideration. Choosing the right UV LED lamp hinges on understanding these needs and possible limitations.

Choosing the right UV LED light lamp requires careful consideration of price, performance, and durability. Research indicates that the price of these lamps can vary widely. High-quality options can range from $50 to $500, but cheaper models often compromise on performance. A 2022 industry report highlighted that consumers prefer durability over initial cost savings. One lamp may appear more affordable but might need frequent replacements, ultimately costing more.

Performance is crucial in selecting a UV LED lamp. Testing shows that more powerful lamps emit higher UV intensities. A lamp with 365 nm wavelength can effectively cure a variety of materials, while those at 395 nm may struggle. Average users might overlook these details, so product specifications are vital. Additionally, it's essential to check the expected lifespan of the LED chips, which can be anywhere from 10,000 to 50,000 hours.

Durability is another common oversight. Some lamps are built with subpar materials that might not withstand daily use. A study found that 30% of cheaper lamps failed within the first year. Investing in better builds can save users from unnecessary replacements. It's beneficial to read user reviews and seek proven longevity, even if the upfront cost is higher. An elegant design might attract users, but it is the internal components that determine longevity. Each decision should reflect not just immediate needs but long-term value as well.

Maintaining your UV LED light lamp can significantly extend its lifespan. Regularly cleaning the lamp with a soft cloth helps remove dust and grime. This simple action keeps the intensity consistent, allowing for optimal performance. Data suggests that proper maintenance can increase the lifespan by up to 30%.

Another vital aspect is to ensure proper ventilation while using the lamp. Overheating can lead to reduced efficiency. A study indicates that 20% of UV lamp failures are due to inadequate cooling. Make sure to avoid placing the lamp in enclosed or poorly ventilated areas. Additionally, keeping the lamp’s surroundings organized minimizes hazards that may affect its functionality.

As time goes on, the UV LEDs may start to dim or become less efficient. It’s wise to monitor their performance regularly. Replacing them after a certain period, even if they seem functional, is a good practice. Some experts recommend changing them every 2,000 hours of use to maintain effectiveness. Keep track of usage hours to ensure replacements occur at appropriate intervals.