Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In today's rapidly evolving industrial landscape, the adoption of advanced technologies has become essential for enhancing efficiency and maximizing output. One such technological advancement is the use of Uv Curing Flood Lamps, which are transforming various sectors by providing a fast, efficient, and environmentally friendly means of curing coatings, inks, and adhesives. According to Dr. Alice Thompson, a leading expert in UV technology, "The Uv Curing Flood Lamp not only accelerates the curing process but also ensures superior quality and durability of the finished products." This statement underscores the growing significance of Uv Curing Flood Lamps in numerous applications.

As industries strive to improve their production capabilities, understanding the applications and benefits of Uv Curing Flood Lamps is vital. These lamps offer a multitude of advantages, including reduced energy consumption, faster drying times, and the ability to cure complex geometries with ease. This guide aims to delve deep into the applications of Uv Curing Flood Lamps, providing insights into how they can be implemented across various sectors, from automotive and aerospace to printing and woodworking. By exploring the benefits they bring, businesses can make informed decisions on incorporating this remarkable technology into their production processes, ultimately leading to enhanced performance and greater sustainability.

UV curing flood lamps are essential tools in various industries, leveraging ultraviolet light to cure or dry inks, coatings, and adhesives almost instantly. These lamps work by emitting UV radiation that triggers photochemical reactions in UV-sensitive materials, facilitating a rapid polymerization process. The mechanism involves the absorption of UV light by photoinitiators in the coating or adhesive, leading to the formation of free radicals that initiate polymer chains, resulting in solidification. This efficiency not only enhances production speeds but also improves the quality of the finished product.

Tips for optimal use of UV curing flood lamps include ensuring proper positioning of the lamp to maximize exposure and maintaining appropriate distance from the material being cured. Regular maintenance of the lamps is crucial to guarantee consistent performance and longevity. To improve energy efficiency, consider using reflective surfaces to direct more UV light onto the target area, minimizing energy waste while achieving effective curing results. Moreover, always adhere to safety guidelines to protect both operators and products during the curing process.

UV curing flood lamps are pivotal in several industries, offering efficient and effective solutions for various applications. In the printing sector, these lamps are extensively used for curing inks and coatings on a multitude of substrates. The rapid curing process enhances productivity and ensures high-quality finishes, making them a favored choice for printing companies looking to streamline their operations. By providing high-intensity UV light, flood lamps enable thorough penetration of coatings, which results in improved durability and resistance to scratches and chemicals.

In the field of electronics, UV curing flood lamps are invaluable for the adhesion of coatings and encapsulants on circuit boards. These lamps cure adhesives in seconds, significantly reducing production times and improving overall efficiency. Moreover, the precise control of UV light exposure allows for the fine-tuning of curing processes, ensuring optimal results without damaging sensitive components. Besides electronics, the automotive industry also benefits from UV curing flood lamps, utilizing them for curing paints and finishes that require quick drying times alongside robust resistance to environmental factors. This versatility across various industries illustrates the broad utility and efficacy of UV curing flood lamps in advancing manufacturing processes.

| Industry | Key Applications | Benefits |

|---|---|---|

| Automotive | Surface coating, adhesion, curing of paints | Fast curing times, high durability, improved appearance |

| Printing | Ink curing for labels, packaging, and decorative printing | Instant print drying, vibrant colors, strong scratch resistance |

| Electronics | Curing of adhesives and coatings for circuit boards | Enhanced reliability, reduction in production time, improved thermal stability |

| Medical | Curing of dental materials and medical devices | Biocompatibility, quick processing, enhanced strength |

| Construction | Curing of coatings, sealants, and adhesives | Faster project completion, superior adhesion, long-lasting results |

The adoption of UV curing flood lamps has revolutionized various industries by providing an efficient alternative to traditional curing methods. One of the primary advantages is the speed at which UV curing takes place. According to a report by RadTech International, UV curing processes can be completed in mere seconds, significantly reducing production time compared to conventional heat-based curing, which may take minutes or even hours. This rapid curing not only boosts productivity but also allows manufacturers to increase output without compromising quality.

Additionally, UV curing flood lamps emit minimal heat, which is crucial for heat-sensitive materials. Traditional curing methods often expose substrates to high temperatures, potentially leading to warping or damage. In contrast, UV lamps maintain a safe thermal environment, preserving the integrity of substrates like plastics and thin films. Research indicates that UV curing can enhance adhesion and improve the overall durability of coatings and films, resulting in higher performance products. As per data from the UV & EB Technology Special Report, 75% of companies reported increased product quality after switching to UV curing technologies, highlighting the method's efficacy and reliability in meeting stringent industry standards.

When using UV flood lamps, safety considerations are paramount to ensure a secure working environment. According to the American National Standards Institute (ANSI), ultraviolet light can potentially cause skin burns or eye injuries if appropriate protective measures are not implemented. Workers must be equipped with proper UV protection gear, including specialized goggles and body covers, to minimize exposure. The Centers for Disease Control and Prevention (CDC) emphasizes that even short-term exposure to UV radiation can lead to adverse health effects. Thus, establishing controlled work zones and using barriers can help reduce risks associated with UV exposure.

Best practices for UV flood lamp usage include regular maintenance and monitoring of UV output intensity. The International Ultraviolet Association (IUVA) highlights in their reports that maintaining optimal lamp conditions is essential for maximizing efficiency and safety. Users should conduct routine inspections to check for lamp degradation, which can lead to excessive exposure and reduced effectiveness. Furthermore, implementing a strict operational protocol, including training staff on the proper use of UV flood lamps, can significantly enhance safety. Keeping the work area well-ventilated and utilizing appropriate shielding will not only protect personnel but also foster a more productive application process.

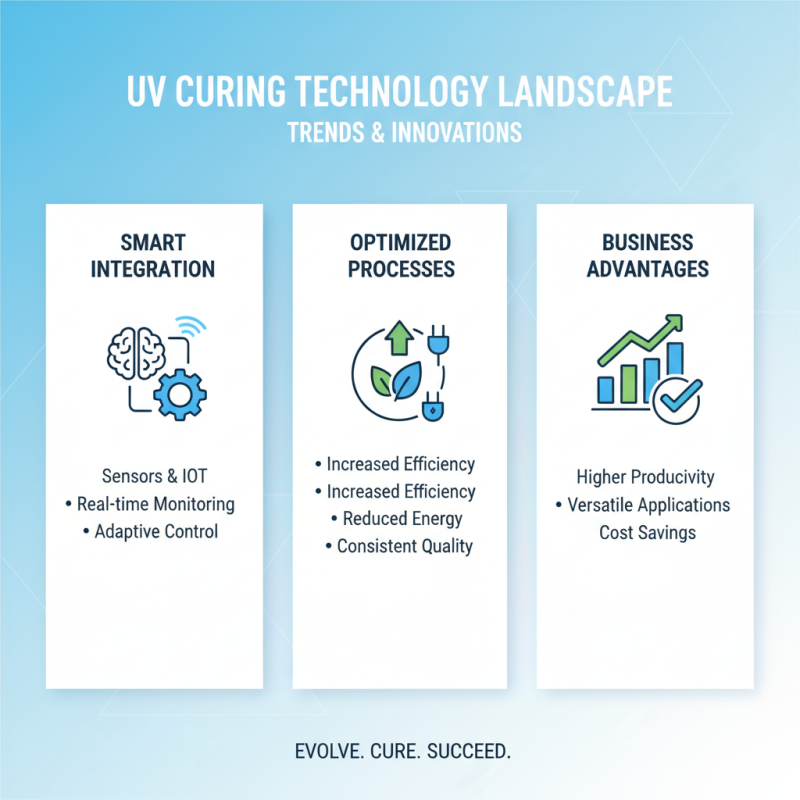

The UV curing technology landscape is rapidly evolving, presenting exciting trends and innovations that enhance efficiency and application versatility. One significant advancement is the integration of smart technology into UV curing systems. This includes sensors and IoT capabilities that allow for real-time monitoring and adjustments, leading to optimized curing processes and reduced energy consumption. Businesses can leverage these innovations to increase productivity while maintaining high-quality output.

Tips for implementing smart UV curing solutions: Start by assessing your current systems and identifying areas where automation could improve performance. Collaborate with technology providers to ensure compatibility and maximize the benefits of data analytics.

Another notable trend is the development of eco-friendly UV curing materials. As the demand for sustainable practices grows, manufacturers are focusing on creating low-VOC and non-hazardous formulations. These advancements not only meet regulatory requirements but also cater to the increasing consumer preference for environmentally conscious products.

Tips for adopting eco-friendly UV materials: Research and choose materials that align with your sustainability goals. Conduct thorough testing to ensure that the performance does not compromise quality, allowing you to market your products as both innovative and environmentally responsible.