Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the ever-evolving landscape of dental and cosmetic applications, LED curing lamps have become an essential tool for professionals seeking to enhance their service offerings. According to Dr. Emily Carter, a leading expert in dental technology, “The precision and efficiency of LED curing lamps have revolutionized the way we approach curing materials.” This statement underscores the pivotal role these devices play in ensuring optimal results in various procedures, including adhesive bonding and resin curing.

LED curing lamps use specific wavelengths of light to polymerize materials quickly and effectively, significantly reducing curing time while improving longevity and performance. As practitioners navigate the selection of the right curing lamp, understanding the underlying technology and best practices becomes crucial. By optimizing their usage of LED curing lamps, professionals can achieve superior outcomes that not only satisfy but also exceed patient expectations.

In this ultimate guide, we will delve into the fundamental principles of LED curing lamps, along with essential tips for optimal use. Whether you are a seasoned practitioner or new to the field, this guide will equip you with the knowledge needed to harness the full potential of LED curing technology, ultimately enhancing the quality of your work and the satisfaction of your clients.

LED curing lamps have revolutionized both dental and industrial applications by offering a rapid and efficient means of polymerizing light-cured materials. These lamps utilize specific wavelengths of light, predominantly in the blue spectrum around 400-500 nm, to activate photoinitiators in resin formulations. According to a report by Grand View Research, the global demand for LED curing lamps is expected to grow at a compound annual growth rate (CAGR) of approximately 5.3% from 2021 to 2028, underscoring their significance in modern curing processes.

Understanding the technology behind LED curing lamps is essential for achieving optimal results. The lights operate on the principle of emitting a continuous wave of light that encourages high levels of efficiency in curing. Research from the Journal of Adhesive Dentistry indicates that LED curing lamps provide better color stability and reduced heat output compared to traditional halogen lamps, which can lead to patient discomfort. Additionally, the longevity and energy efficiency of LED lamps, often lasting up to 50,000 hours, make them a sustainable choice for both dental professionals and manufacturers alike.

Effective usage of LED curing lamps requires awareness of various factors, including lamp placement and exposure time. Studies suggest that proper distance—typically around 1 cm from the material—and a curing time ranging from 10 to 40 seconds can significantly enhance the adhesion and longevity of the cured materials. It is crucial for users to be trained in these parameters to leverage the full potential of LED curing technology, as improper use can lead to incomplete curing and compromised material performance.

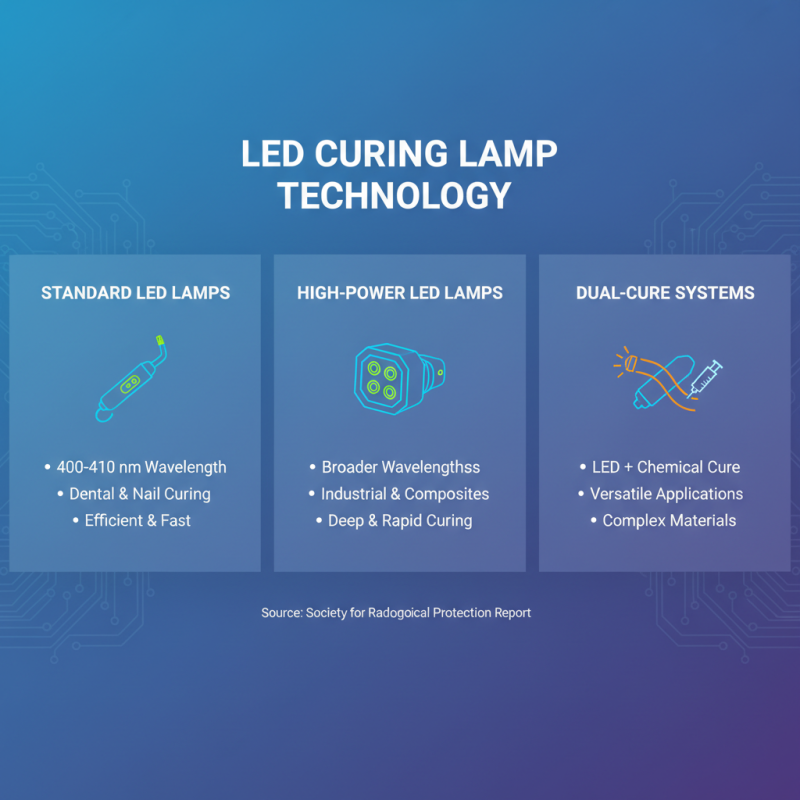

LED curing lamps have revolutionized the field of photopolymerization, offering various options tailored to specific applications. The predominant types include standard LED lamps, high-power LED lamps, and dual-cure systems. Standard LED curing lamps typically emit light in a narrow wavelength range of 400-410 nm, effectively curing most dental and nail care materials, making them ideal for general use. According to a report from the Society for Radiological Protection, these lamps achieve optimal curing depth and speed, significantly enhancing workflow efficiency.

High-power LED curing lamps, on the other hand, provide increased light intensity, which results in faster curing times. These lamps are particularly beneficial in professional settings requiring rapid and durable curing of thick materials. A study published in the Journal of Dental Research indicated that high-power LEDs reduce the curing time by approximately 50% compared to traditional curing methods, leading to improved productivity in dental practices.

Lastly, dual-cure systems integrate both LED and chemical activation, offering versatility for materials that require varying curing methods. This combination allows practitioners to effectively use a wider range of materials while ensuring complete polymerization. The American Dental Association highlights that utilizing a dual-cure system results in superior bond strengths, offering optimal performance for complex restorations, thereby expanding the utility of LED curing lamps in modern dental and cosmetic applications.

When selecting the right LED curing lamp, it's essential to first assess the specific needs of your projects. Think about the materials you use regularly, such as gel polishes, adhesive resins, or coatings, as different lamps offer varying levels of intensity and wavelength output. Understanding the curing process involved with your materials will help narrow down your options. For example, some UV-cured products may require a specific wavelength for optimal hardening, while others can effectively cure across a broader spectrum.

Another important factor to consider is the size and design of the lamp. Whether you're working in a professional salon or setting up a home workstation, the lamp's portability and size can significantly impact convenience and efficiency. Larger lamps may provide faster curing times, while compact models are great for precise, detailed work. Additionally, consider features like timer settings, heat control, and ease of cleaning, as these can enhance your overall experience and productivity. By thoughtfully weighing these factors, you can choose an LED curing lamp that perfectly fits your needs and maximizes your curing process.

When utilizing LED curing lamps, it's crucial to adapt their use based on specific applications to achieve the best results. In dental practices, for example, ensuring the correct distance between the lamp and the material can significantly enhance the curing process. A typical recommendation is to keep the lamp about 1-2 mm away from the surface to optimize light absorption for materials like composites and adhesives.

Another key aspect lies in understanding the ideal curing times for different materials. Each material may have a recommended exposure time for the LED light, so it's vital to follow these guidelines closely. For instance, thicker materials may require longer curing times to ensure complete polymerization, whereas thinner layers may cure faster. Always refer to the manufacturers' specifics for the most effective use.

Lastly, maintaining the cleanliness of the LED light lens is essential for optimal performance. Dust and debris can obstruct the light, diminishing its effectiveness. Regularly cleaning the lamp lens with a soft cloth will ensure consistent curing results across various applications. By implementing these tips, users can maximize the performance and longevity of their LED curing lamps in diverse settings.

When using LED curing lamps, maintenance and safety considerations are paramount to ensure longevity and effectiveness. Regular cleaning of the lamp's surface is essential to remove dust and residues that may hinder its performance. It’s recommended to use a soft, lint-free cloth and an appropriate cleaning solution to avoid damage to the lamp. Regularly inspect the lamp for any signs of wear or damage, including cracks or discoloration, and replace parts as necessary to maintain optimal function.

Safety is another critical aspect when operating LED curing lamps. Always follow the manufacturer’s guidelines for usage and ensure proper ventilation in the curing area. Protective eyewear should be worn to shield against intense light exposure, as LED lamps can emit harmful UV rays. Additionally, maintaining a safe distance between the lamp and the work surface can prevent overheating and potential hazards. Familiarizing yourself with the lamp’s features, including any emergency shut-off mechanisms, can enhance safety during use, ensuring a secure and efficient working environment.

| Feature | Description | Maintenance Tips | Safety Considerations |

|---|---|---|---|

| Wavelength | Typically ranges from 320 to 500 nm | Regularly check bulb integrity and replace as needed to maintain optimal performance. | Always wear UV protective eyewear when operating. |

| Curing Time | Typically requires 30 seconds to 2 minutes based on the material. | Clean the lamp's glass surface to ensure efficient curing. | Do not look directly into the light during operation. |

| Power Consumption | Generally low power usage compared to traditional curing methods. | Ensure proper ventilation around the lamp to prevent overheating. | Keep out of reach of children and pets. |

| Portability | Many models are lightweight and easy to transport. | Store in a safe, dry place when not in use to protect from damage. | Avoid using near flammable materials. |

| Noise Level | Operates quietly, making it ideal for various environments. | Check for any unusual sounds during operation and service if necessary. | Follow manufacturer guidelines for safe operation. |