Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the application of Ultraviolet Light Systems has gained significant traction across various industries, driven by their effectiveness in disinfection and sterilization. According to a report by MarketsandMarkets, the global UV light market is expected to grow from $2.8 billion in 2020 to $6.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 19.5%. This growth is largely attributed to the increasing demand for advanced water treatment solutions and the need for improved air quality in residential and commercial spaces. Additionally, the COVID-19 pandemic has accelerated the adoption of UV technology in high-traffic environments to ensure safety and health compliance. As organizations seek innovative methods to combat pathogens and enhance operational efficiency, understanding the functionality of Ultraviolet Light Systems becomes crucial for leveraging their full potential in modern applications.

Ultraviolet (UV) light plays a significant role in various modern applications, with its types and properties influencing how technologies are developed and utilized. UV light is classified into three main types: UVA, UVB, and UVC. Each type has distinct properties and applications; for instance, UVA is primarily associated with skin aging while UVC is most effective for germicidal purposes. The shorter wavelengths of UV light present unique challenges and opportunities in fields ranging from water treatment to antimicrobial technologies.

One promising application of UV light is in enhancing the degradation of pollutants, such as estrone, a contaminant commonly found in water sources. Recent developments in heterostructures combining Zn–Cr layered double hydroxides with g-C3N4 have showcased improved efficiency under UV and visible light, suggesting potential advancements in environmental remediation.

**Tips:** When working with UV systems, consider the specific wavelength needed for your application to ensure efficacy. Additionally, explore the latest innovations in UV technology to maximize performance, especially in fields like sustainable packaging or biomedical applications, which benefit from advanced UV filtering and antimicrobial properties.

| Type of Ultraviolet Light | Wavelength Range (nm) | Common Applications | Safety Considerations |

|---|---|---|---|

| UVA | 320-400 | Tanning beds, curing processes | Can cause skin damage with prolonged exposure |

| UVB | 280-320 | Vitamin D synthesis, sunburn prevention | Higher risk of skin cancer with overexposure |

| UVC | 100-280 | Disinfection, sterilization, water purification | Can cause eye damage and skin burns; protective gear is required |

| Excimer Lasers | Varies (usually UVC range) | Medical procedures, photolithography | Protective eyewear necessary; specific safety protocols required |

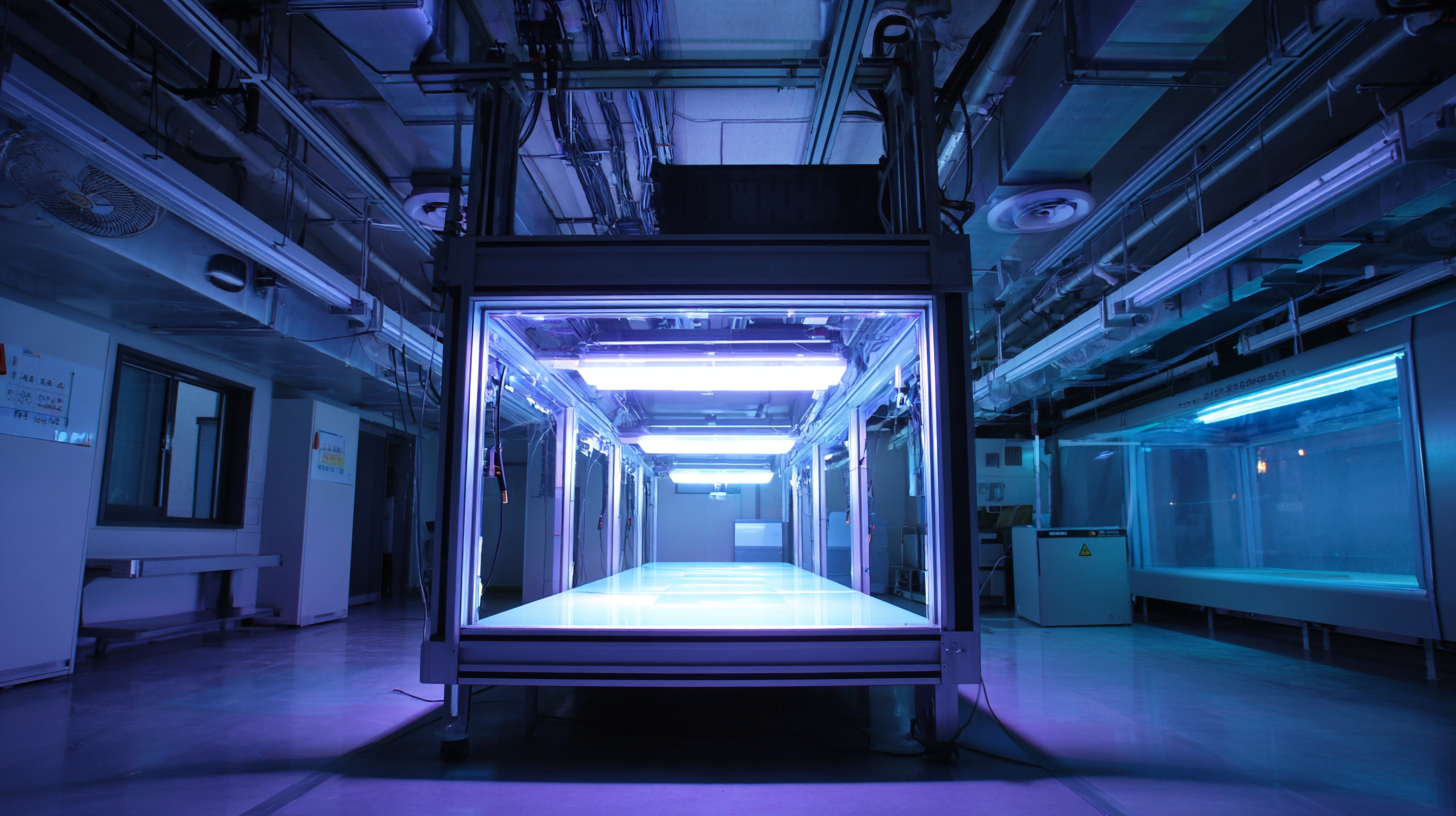

Ultraviolet (UV) light systems are increasingly utilized across various modern applications due to their unique scientific principles. At its core, ultraviolet light encompasses wavelengths shorter than visible light, with the ability to disinfect and sterilize environments effectively. This functionality stems from the capacity of UV rays to damage the nucleic acids within microorganisms, rendering them inactive. The germicidal properties of UV-C light, for instance, have made it an essential tool in healthcare settings, water treatment facilities, and even air purification systems.

Ultraviolet (UV) light systems are increasingly utilized across various modern applications due to their unique scientific principles. At its core, ultraviolet light encompasses wavelengths shorter than visible light, with the ability to disinfect and sterilize environments effectively. This functionality stems from the capacity of UV rays to damage the nucleic acids within microorganisms, rendering them inactive. The germicidal properties of UV-C light, for instance, have made it an essential tool in healthcare settings, water treatment facilities, and even air purification systems.

The effectiveness of UV light systems can be attributed to the interactions between photons and biological molecules. When UV light strikes a pathogen, such as bacteria or viruses, it instigates a photochemical reaction that can lead to mutations or cell death. This principle is harnessed in various technologies, such as UV lamps and LEDs, which are designed to optimize the emission of UV wavelengths for maximum effectiveness. As scientists continue to explore and refine these applications, the potential for UV systems to combat emerging health threats remains promising, paving the way for innovative solutions in public health and safety.

Ultraviolet (UV) light systems have emerged as vital tools in modern healthcare and sanitation applications, providing a powerful means to combat pathogens and enhance safety across various environments. According to a report by the World Health Organization, UV light can effectively inactivate up to 99.9% of viruses and bacteria within seconds, making it an indispensable asset in hospitals, laboratories, and public spaces. The adoption of UV disinfection systems has surged, particularly in response to the COVID-19 pandemic, as healthcare facilities seek to maintain sterile environments and reduce infection transmission.

One key application of UV light is in the surface disinfection of medical equipment and high-touch areas such as doorknobs and countertops. The Centers for Disease Control and Prevention (CDC) endorses UV disinfection, citing its efficiency in eradicating harmful microorganisms without leaving chemical residues. For more effective outcomes, it is recommended to ensure that all surfaces are free of organic materials before applying UV light, as this allows for optimal exposure and disinfection efficacy.

In addition to surface disinfection, UV light is increasingly utilized in water treatment systems to eliminate pathogens from drinking water. The Environmental Protection Agency (EPA) reports that UV treatment can significantly reduce the presence of harmful contaminants without affecting the water's taste or odor. To maximize the effectiveness of UV water treatment, users should regularly check lamp intensity and ensure proper maintenance of the system for consistent performance.

Ultraviolet (UV) light technology has seen significant innovations that enhance its role in various industrial applications. One of the most notable advancements is the development of high-intensity UV-C lamps that effectively inactivate pathogens and disinfect surfaces in a matter of seconds. Industries such as healthcare, food processing, and pharmaceuticals have adopted these systems to ensure safety and compliance with sanitation standards. By employing advanced UV technologies, facilities can significantly reduce the reliance on harmful chemicals, promoting a more eco-friendly approach to disinfection.

In addition to disinfection, UV light systems are now being utilized in curing processes for inks, adhesives, and coatings. Recent innovations in UV LED technology have made it possible to achieve faster curing times with lower energy consumption compared to traditional methods. This not only improves production efficiency but also minimizes waste, as less material is required due to the precise application of UV light. As industries continue to embrace these advancements, the applications of ultraviolet light technology will likely expand even further, redefining operational standards across sectors.

When utilizing ultraviolet (UV) light systems in various modern applications, safety should always be a top priority. UV light can be beneficial for disinfection, curing, and even in phototherapy, but the potential hazards associated with its exposure must be carefully managed. It’s essential to always use UV protective gear, such as goggles and gloves, to shield your skin and eyes from harmful exposure. Awareness of the type of UV light being used – whether UV-A, UV-B, or UV-C – is crucial, as each type has different exposure risks and applications.

Tips: Always ensure that the UV light system is equipped with safety features such as automatic shut-off switches and protective covers. Regular maintenance and checks should be performed to ensure the equipment is functioning properly and does not pose any risks. Additionally, restrict access to areas where UV light systems are employed, and provide thorough training for all personnel involved in handling or operating the equipment to mitigate any accidental exposure.

Another important consideration is to adhere strictly to manufacturer guidelines regarding usage and maintenance. Overexposure can lead to serious health issues, so it’s vital to follow the recommended exposure times and operational protocols. Incorporating UV warning signs in work areas can serve as a daily reminder of safety practices and help maintain a safety-first environment.