Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

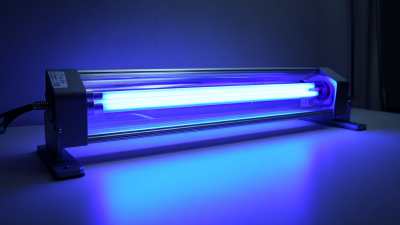

In recent years, the utilization of UV curing light sources has revolutionized various industries, from printing and coatings to electronics and dentistry. According to a report by MarketsandMarkets, the UV curing market is projected to reach $3.68 billion by 2026, growing at a CAGR of 10.6% during the forecast period. This growth is driven by the increasing demand for environmentally friendly and energy-efficient curing solutions, as UV curing processes minimize the use of volatile organic compounds (VOCs). Choosing the right UV curing light source is crucial for achieving optimal results in your production processes, as different applications require specific wavelengths, intensities, and configurations. Understanding the diverse types and technologies available in the market can help businesses optimize their operations, enhance product quality, and meet regulatory standards.

When considering UV curing technology, it's vital to understand its underlying principles and applications. UV curing utilizes ultraviolet light to initiate a photopolymerization process, converting liquid resins into solid materials almost instantly. This technology offers significant advantages, such as rapid curing times and energy efficiency, making it highly beneficial across various industries, from printing to coatings. For example, modified castor oil-based UV/thermal dual-curing coatings have demonstrated exceptional properties, showcasing the versatility of this approach.

When considering UV curing technology, it's vital to understand its underlying principles and applications. UV curing utilizes ultraviolet light to initiate a photopolymerization process, converting liquid resins into solid materials almost instantly. This technology offers significant advantages, such as rapid curing times and energy efficiency, making it highly beneficial across various industries, from printing to coatings. For example, modified castor oil-based UV/thermal dual-curing coatings have demonstrated exceptional properties, showcasing the versatility of this approach.

Tips: When selecting a UV light source, ensure it aligns with the specific material you intend to cure. Different resins may require specific wavelengths for optimal curing. Additionally, consider the intensity and coverage of the light source, as these factors significantly influence cure efficiency and overall performance.

Understanding the applications of UV curable materials is equally crucial. They have revolutionized printing technologies, creating smart materials that can adapt and respond to their environment. Familiarize yourself with recent advancements in the field, including cationic UV-curing techniques, which expand the potential applications of these materials.

Tips: Research and evaluate the latest products in UV curing to stay updated on innovations like bio-based coatings and advanced photo-crosslink hydrogels. These developments can enhance your processes and improve sustainability in your operations.

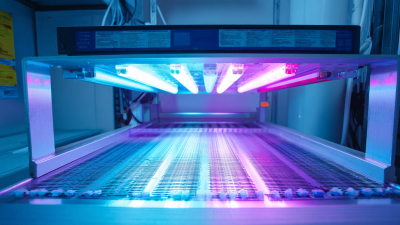

When selecting the best UV curing light source for your industry, it's essential to identify the specific needs and challenges unique to your operations. Different sectors, such as automotive, medical, or printing, may require various intensities, wavelengths, and curing speeds. Start by analyzing the materials you'll be curing and the desired outcome, as this will guide your choice.

Tip 1: Evaluate Material Compatibility - Ensure that the UV light source you select is compatible with the resins or coatings you're using. Some materials may require specific wavelengths for effective curing, which can impact the final product's quality.

Tip 2: Consider Environment and Space - The environment in which you'll be using the UV curing light is also crucial. If your facility has space constraints or specific safety regulations, portable or compact units with built-in safety features may be more beneficial.

Tip 3: Assess Production Volume - Finally, think about your production volume. A high-output UV curing system may be necessary if you're operating on a large scale. Conversely, smaller projects might only require a handheld unit. Balancing these factors will help in choosing the best UV curing light source tailored to your industry's needs.

| Industry | UV Curing Light Type | Wavelength Range | Typical Applications | Output Power |

|---|---|---|---|---|

| Printing | Mercury Vapor Lamp | 200-400 nm | Ink curing | 100-120 W/cm |

| Automotive | LED Curing Light | 350-410 nm | Adhesives, coatings | 10-30 W/cm |

| Electronics | UV LED Flood Light | 365 nm | PCB coatings | 5-15 W/cm |

| Medical | Low-Pressure Mercury Lamp | 254 nm | Sterilization, coatings | 20-40 W/cm |

| Packaging | LED Light Engine | 365-395 nm | Label curing, coatings | 15-25 W/cm |

When selecting the right UV curing light source for your industry, it’s crucial to understand the various types available, each with its own set of pros and cons. Mercury vapor lamps, for example, are traditional and widely used, offering high intensity and effective curing. However, they have longer warm-up times and can be less energy efficient. On the other hand, LED UV light sources are gaining popularity due to their instant on/off capabilities and lower energy consumption. They, however, might not cure all types of inks and coatings as effectively as mercury lamps.

Tip: Always consider the specific materials and applications in your industry. If you frequently work with different substrates or coatings, a flexible light source that can handle a range of formulations might be essential. Additionally, think about maintenance costs; LED systems, for instance, typically require less frequent bulb replacements.

When evaluating the options, also consider factors such as the size of your workspace and the level of mobility you need. For industries with space constraints, compact UV light sources can provide powerful curing in a smaller footprint, making them ideal for tight environments without sacrificing performance.

When selecting a UV curing light source for your industry, there are several key features to consider that can significantly impact efficiency and effectiveness. First and foremost, the wavelength of the UV light is critical, as different applications may require specific wavelengths for optimal curing. For instance, UV LED systems typically operate between 365 nm and 405 nm, making them suitable for various coatings and adhesives. It's essential to match the UV light source with the materials you intend to cure to ensure proper adhesion and curing times.

Another vital aspect is the intensity and output of the UV light source. Higher intensity lights can cure materials more quickly, increasing productivity in a manufacturing setting. Look for systems that offer adjustable intensity settings, which allow you to manage the curing process depending on the material and application density. Additionally, consider the size and portability of the curing unit. Compact and mobile UV light sources can be advantageous for businesses that require flexibility in their workspace. Investing in a system that combines these features will enhance your production capabilities and overall operational efficiency.

When selecting a UV curing light source for your industry, budget considerations are paramount. It's essential to understand that the cheapest option isn't always the best. While cutting costs might provide immediate savings, investing in higher-quality equipment can offer superior efficiency and longevity. A reliable UV curing system not only ensures better curing results but also minimizes maintenance costs and downtime, ultimately leading to greater productivity and profitability in the long run.

Balancing cost and quality involves evaluating the specific needs of your operations. Assessing the scale of production, the materials being cured, and the desired curing speed will guide your decision-making process. Many manufacturers offer a range of options that vary in price and performance; therefore, it's wise to analyze the total cost of ownership. This includes initial investment, energy consumption, and the expected lifespan of the equipment. By carefully weighing these factors, businesses can strategically choose a UV curing solution that aligns with their budget while meeting quality requirements.