Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right UV curing flood lamp is crucial for various industries. The global UV curing market is projected to reach $5 billion by 2026. This growth indicates rising demand in printing, coatings, and adhesives.

Different applications require specific features. For example, a UV curing flood lamp should emit the right wavelength. UV-A or UV-C wavelengths vary based on the materials you are curing. Moreover, the lamp's intensity affects curing speed. Higher intensity can lead to faster processing times.

However, selecting the perfect lamp can be challenging. Many users overlook factors like heat emission and energy consumption. These elements can impact production efficiency. Conducting thorough research can help avoid costly mistakes. Finding a UV curing flood lamp that fits your needs requires careful consideration. It’s not just about the price; effectiveness matters too.

UV curing technology has transformed various industries by providing a fast and efficient drying method for inks, coatings, and adhesives. This process utilizes ultraviolet light to initiate polymerization, allowing materials to cure almost instantly. According to a 2022 report by the RadTech organization, the UV curing market is expected to grow at a compound annual growth rate (CAGR) of 8.1% from 2023 to 2030. This is largely due to its wide applications in manufacturing, automotive, and printing sectors.

Understanding the different types of UV lamps is crucial for making informed decisions. UV flood lamps provide uniform light exposure over a large area. They are essential for achieving consistent curing, especially in complex geometries. However, improper selection can lead to issues like under-curing. A study by the UV & EB Technology Association indicated that 25% of manufacturers encountered problems due to choosing the wrong lamp output. Not all UV lamps are created equal; variations in intensity and wavelength can significantly impact the curing process.

Moreover, it’s essential to consider the lamp's longevity and maintenance needs. Many users fail to account for the cost-effectiveness of replacement bulbs. Some lamps may require frequent adjustments, leading to downtime. Balancing performance with economic factors is often a challenge for businesses. It’s vital to weigh the pros and cons carefully when selecting a UV curing solution, as every choice can affect overall productivity and quality.

| Lamp Type | Wattage | Wavelength (nm) | Curing Area (sq ft) | Application | Cooling Type |

|---|---|---|---|---|---|

| High-Pressure Mercury Lamp | 300W | 320-500 | 10 | Ink & Coatings | Air-cooled |

| LED UV Lamp | 200W | 365 | 5 | Plastics & Electronics | Passive cooling |

| Medium Pressure Mercury Lamp | 250W | 320-410 | 8 | Wood & Metal Finishing | Water-cooled |

| Flash Curable Lamp | 400W | 400 | 12 | Graphics & Labels | Air-cooled |

| UV Arc Lamp | 500W | 254 | 15 | Textiles & Papers | Air-cooled |

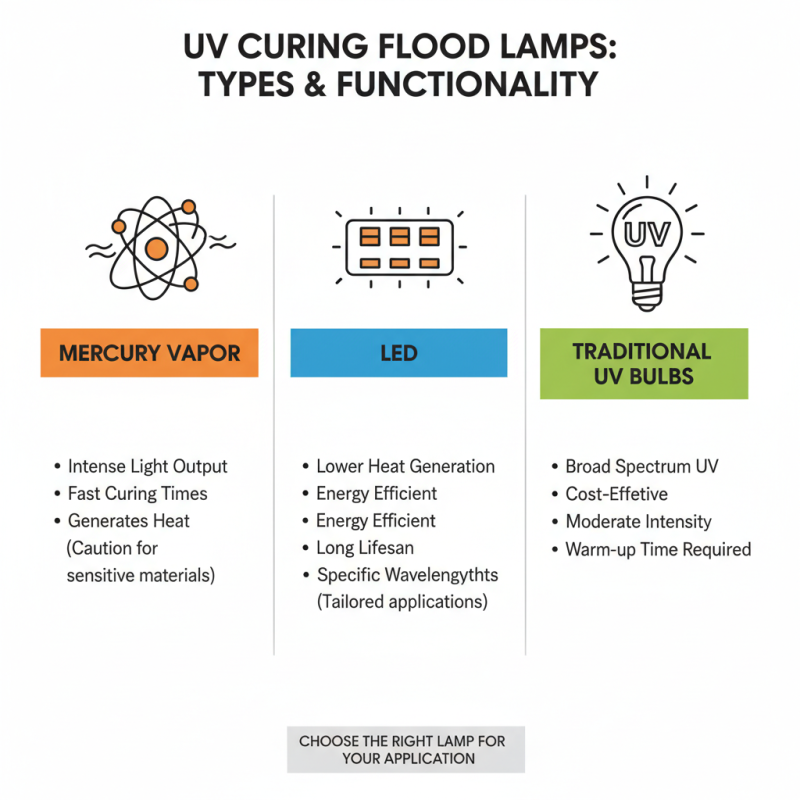

When selecting a UV curing flood lamp, it's essential to understand the various types and their functionalities. Broadly, UV flood lamps can be categorized into mercury vapor, LED, and traditional UV bulbs. Each type has unique characteristics and benefits tailored to specific applications. For example, mercury vapor lamps offer intense light output, allowing for fast curing times. However, they can generate excessive heat, which may not be ideal for sensitive materials.

On the other hand, LED UV flood lamps are gaining popularity. They provide consistent output, consume less energy, and last longer than traditional bulbs. The flexibility in curing times is a definite plus. However, they may require specific photoinitiators in resin formulations, potentially complicating material compatibility.

Traditional UV bulbs are often more affordable but have shorter lifespans and higher energy consumption. They can also struggle with uniform light distribution. Evaluating these differences is crucial. Consider what materials you will cure and any specific application needs. Reflecting on aspects like heat sensitivity, curing speed, and energy efficiency will help determine the right choice for your operations.

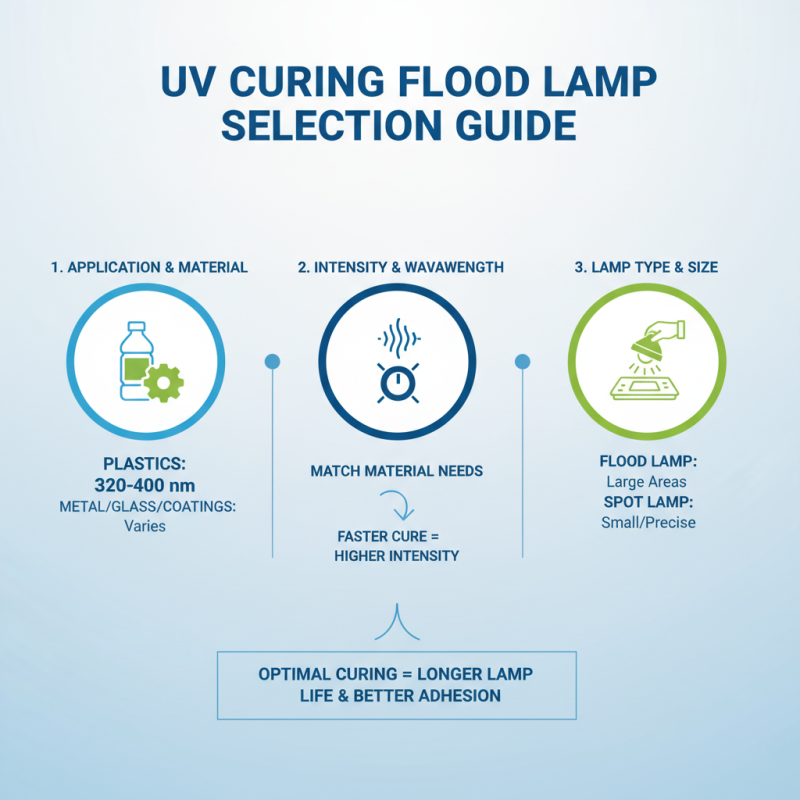

Choosing the right UV curing flood lamp involves several key factors. Understanding the application is essential. Different materials require different intensities and wavelengths. For instance, plastics often need a UV range of 320 to 400 nanometers for effective curing. In contrast, other materials like metal may have different needs.

Another crucial aspect is the intensity of the lamp. Industry reports show that intensity directly affects curing speed and quality. For optimal performance, a lamp should provide at least 200 mW/cm². This level ensures proper curing without defects. A weak lamp might not penetrate thicker coatings, leading to under-cured surfaces. This can be costly in the long run, causing product failures and increased rework.

Cooling methods are also important. High-intensity UV lamps generate heat. Proper cooling mechanisms extend lamp life and maintain consistent output. Ignoring cooling can lead to lamp failure or inconsistent curing results. Some users fail to consider this, resulting in downtime and additional repair costs. Always review the specifications before making a choice. Balancing intensity, wavelength, and cooling will help meet specific needs effectively.

When selecting a UV curing flood lamp, understanding the UV output and wavelength is essential. Different applications require specific wavelengths for optimal performance. For instance, some materials cure better under UV-A light, while others may need UV-C or even visible light. Knowing your material's needs can dramatically affect the curing process.

Consider how intensity impacts curing speed. A higher intensity may expedite the process but could lead to excess heat. This could warp sensitive materials. Testing various setups can help find the right balance. Inadequate testing can lead to unexpected results. The wavelength also affects depth penetration. Deeper curing might be necessary for thicker materials, but it requires careful calibration.

Maintaining awareness of these factors will guide your choice. Don't be afraid to experiment with different lamp positions and distances. Adjusting the distance can radically change the UV exposure. This trial and error approach often uncovers valuable insights. Keep track of your findings, as consistency is crucial for repeatable results.

Choosing a UV curing flood lamp involves balancing cost and quality. Quality lights ensure efficient curing, while cheaper options may compromise results. It’s crucial to analyze your needs. Consider the materials you're working with and the required curing speed. Sometimes, spending more upfront saves costs in failed projects later on.

Tips: Check for reviews online. User feedback can reveal real-world performance. Compare specifications thoroughly. Don’t get swayed by price alone. A well-built lamp might only seem slightly more expensive. Yet, it can last longer and provide better results.

Beware of low-cost options that lack durability. You might face more maintenance issues down the road. Not all lamps deliver consistent UV output, leading to uneven curing. Analyze which features matter most for your applications. If you're unsure, consulting with industry experts can be invaluable. Always keep your long-term goals in mind.