Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

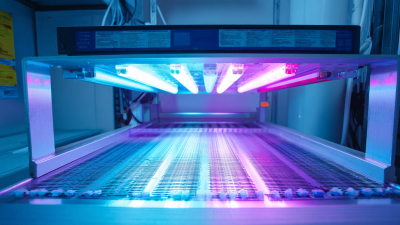

In the rapidly evolving landscape of manufacturing and printing, the demand for efficiency and quality has led to the widespread adoption of UV LED curing devices. According to a recent market report by Research and Markets, the global UV curing market is projected to reach $4.95 billion by 2027, growing at a CAGR of 8.3% from 2020. This surge is primarily driven by the increasing need for faster curing processes and eco-friendly solutions across various industries, including printing, coatings, and adhesives.

The UV LED curing device stands out as a game-changer, offering unique advantages such as lower energy consumption, reduced heat generation, and instant curing capabilities. In this blog, we will explore the 10 best UV LED curing devices of 2023, highlighting their features and benefits to enhance operational efficiency and meet the growing demands of modern manufacturing.

UV LED curing technology has revolutionized various industries by offering significant advantages over traditional curing methods. This technology is known for its energy efficiency, achieving up to 98% savings compared to traditional mercury UV curing systems. As highlighted in recent market analyses, the UV LED market is projected to experience substantial growth, reaching a forecasted value by 2032, driven by applications in sectors such as UV curing, purification, and counterfeit detection.

Innovative solutions are emerging as more companies adopt UV LED curing technology to enhance their production processes. For instance, the introduction of advanced UV printing technology in PCB design showcases how UV-curable inks can deliver high-resolution images with remarkable vibrancy, meeting the increasing demands for quality and efficiency. Moreover, with 80% of operations in certain businesses now utilizing UV LED technology, it's clear that this shift is not just a trend but a fundamental change that is shaping the future of manufacturing and design. As the industry continues to evolve, the benefits of UV LED curing will likely expand, creating new opportunities and efficiencies across diverse applications.

In 2023, while UV LED curing devices are increasingly praised for their efficiency and energy savings, users still encounter several common issues that can hinder performance. One notable challenge is the inconsistency in curing times, which can vary due to factors like ambient temperature and material type. According to a report from the International UV Association, improper settings can lead to under-curing, resulting in weak adhesion and increased production errors. It is essential to calibrate devices correctly to match the specific requirements of the materials being used.

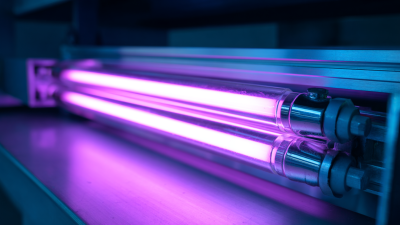

Another significant issue is the longevity of the UV LED bulbs. A study by Smithers Pira highlighted that, while UV LED technology offers longer lifespans compared to traditional UV lamps, the degradation over time can lead to reduced curing performance. Regular maintenance and timely replacement of bulbs are crucial to ensure optimal function.

Tip: To ensure uniform curing, conduct periodic tests with a variety of materials and document the optimal settings.

Users should also be aware of the potential for overheating, which can impact both the device and the materials being cured. Implementing monitoring systems can help manage temperatures effectively.

Tip: Employ cooling mechanisms or allow devices to rest during prolonged operations to prevent overheating and ensure quality outputs.

When considering curing methods for various applications, the debate between UV LED and traditional curing techniques is significant. UV LED curing devices have gained popularity for their efficiency and effectiveness. Unlike traditional methods that rely on mercury vapor lamps, UV LED systems operate at lower temperatures and offer a more targeted wavelength, which can enhance the curing process and reduce energy costs.

Incorporating UV LED technology not only speeds up production times but also minimizes the environmental impact. Since UV LED lights last longer and contain no hazardous materials, they make a safer choice for both users and the environment. As businesses seek to streamline their processes and reduce costs, transitioning to UV LED curing can present a compelling advantage over traditional methods.

**Tip:** When choosing a UV LED curing device, consider the specific materials you will be using. Different substrates may require unique wavelengths for optimal curing results. **Tip:** Regular maintenance and cleaning of your UV LED device can prolong its lifespan and ensure consistent performance. With the right approach, businesses can maximize efficiency and product quality while embracing modern curing solutions.

| Device Type | Curing Speed (seconds) | Wavelength (nm) | Power Consumption (W) | Portability | Average Price (USD) |

|---|---|---|---|---|---|

| Desktop UV LED Curing Lamp | 30 | 395 | 48 | No | 150 |

| Portable UV LED Curing Device | 20 | 405 | 28 | Yes | 90 |

| Handheld UV LED Curing Tool | 10 | 385 | 15 | Yes | 70 |

| UV LED Nail Curing Lamp | 60 | 365 | 36 | No | 40 |

| Industrial UV LED Curing Station | 15 | 395 | 120 | No | 1200 |

| UV LED Glue Curing Light | 25 | 400 | 24 | Yes | 65 |

When selecting the right UV LED curing device, it’s essential to consider several key factors that directly impact efficiency and effectiveness. Firstly, evaluate the curing speed required for your specific applications. Different devices may vary significantly in their curing times, and opting for one with faster curing capabilities can greatly enhance productivity in a professional setting.

Another critical factor is the wavelength of the UV light emitted by the device. Ensure that the wavelength is compatible with the materials you will be curing, as certain resins and coatings react better to specific wavelengths. Additionally, assess the device's design and portability; a lightweight, compact model may be more suitable for a mobile workspace, while a larger unit could serve well in a stationary setup.

Lastly, consider the energy efficiency and longevity of the UV LED bulbs. Investing in devices that use high-quality, durable LED technology not only saves on replacement costs but also reduces power consumption. These features collectively contribute to the overall performance and operational costs of the curing process, making them vital elements in your decision-making.

To maximize the efficiency of UV LED curing devices, regular maintenance practices are essential. One of the most crucial steps is to keep the curing units clean to prevent any dust or resin buildup that could affect performance. Using a soft, lint-free cloth and appropriate cleaning solutions can help maintain the integrity of the LED lenses and surrounding surfaces. Additionally, operators should frequently inspect the device for any signs of wear and tear, ensuring that the bulbs are functioning optimally to provide consistent curing results.

Another effective practice is to calibrate the curing units regularly. This involves checking the exposure times and intensity settings to ensure they are aligned with the specific materials being cured. Over time, materials and methods may change, requiring adjustments to achieve the best results. Moreover, keeping a log of maintenance activities can be beneficial for tracking performance and identifying any trends that may indicate a need for professional servicing. Implementing these maintenance practices can significantly enhance the longevity and efficiency of UV LED curing devices, leading to improved productivity in any curing operation.

This chart displays the efficiency ratings of the top 10 UV LED curing devices based on various factors. The ratings reflect the average curing speed, energy consumption, and overall performance. This data can help users select the most efficient device for their needs.