Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

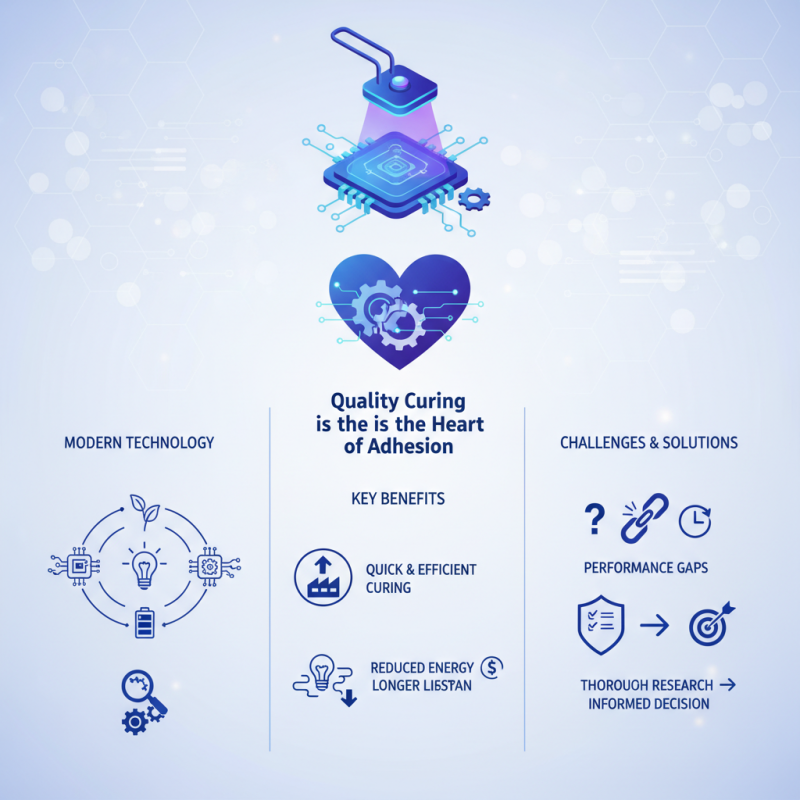

In the world of modern technology, the Uv Led Curing Device stands out as a vital tool. Experts like Dr. Emily Sanders, a leading figure in photonics, have emphasized, "Quality curing is the heart of adhesion." This statement reflects the critical role these devices play across various industries, especially in printing, coatings, and manufacturing.

Uv Led Curing Devices utilize innovative technology to provide quick and efficient curing processes. They offer a significant advantage over traditional curing methods. Users often appreciate the reduced energy consumption and longer lifespan of these devices. However, not all products deliver the same performance, creating a challenge for potential buyers.

It's essential to acknowledge some shortcomings in the market. Many devices may not meet user expectations in terms of speed or quality. Thorough research is necessary to identify the right Uv Led Curing Device that suits specific needs. A well-informed decision can vastly improve efficiency and output quality.

UV LED curing devices are revolutionizing the way we approach curing processes. These devices use ultraviolet light to initiate chemical reactions, primarily curing resins and coatings. With rising interest in efficiency, UV LED curing technology is gaining traction across various industries. In fact, a report by MarketsandMarkets predicts that this market will grow at a CAGR of 12.5% by 2025.

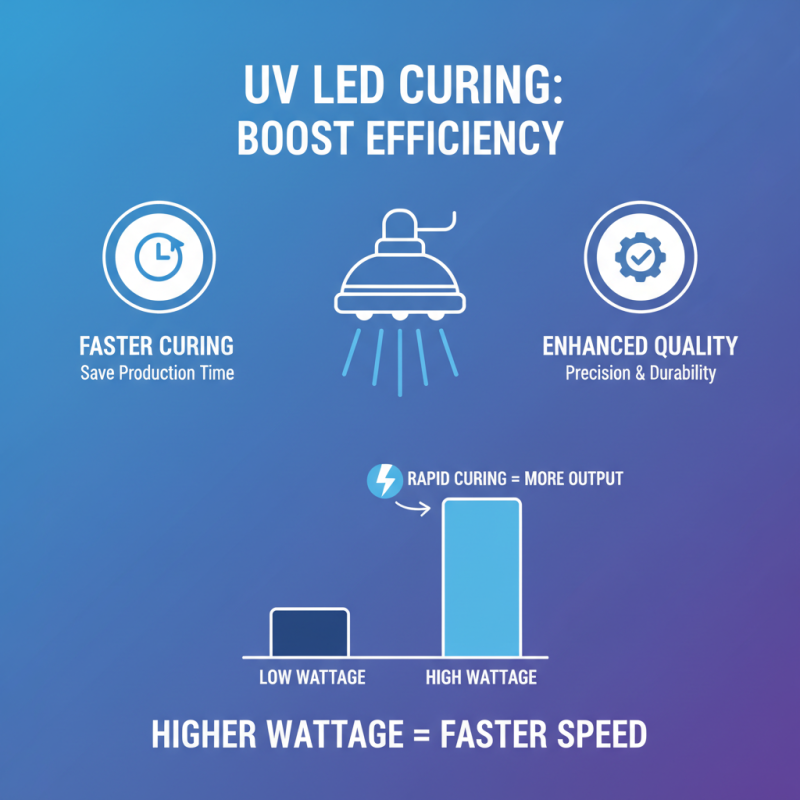

The efficiency of UV LED curing is significant. Unlike traditional curing methods, UV LEDs offer faster curing times, often in seconds. They also consume less energy, making them environmentally friendly. However, the initial cost of these devices can be high, which deters some users. It's essential to weigh the long-term savings against these upfront investments.

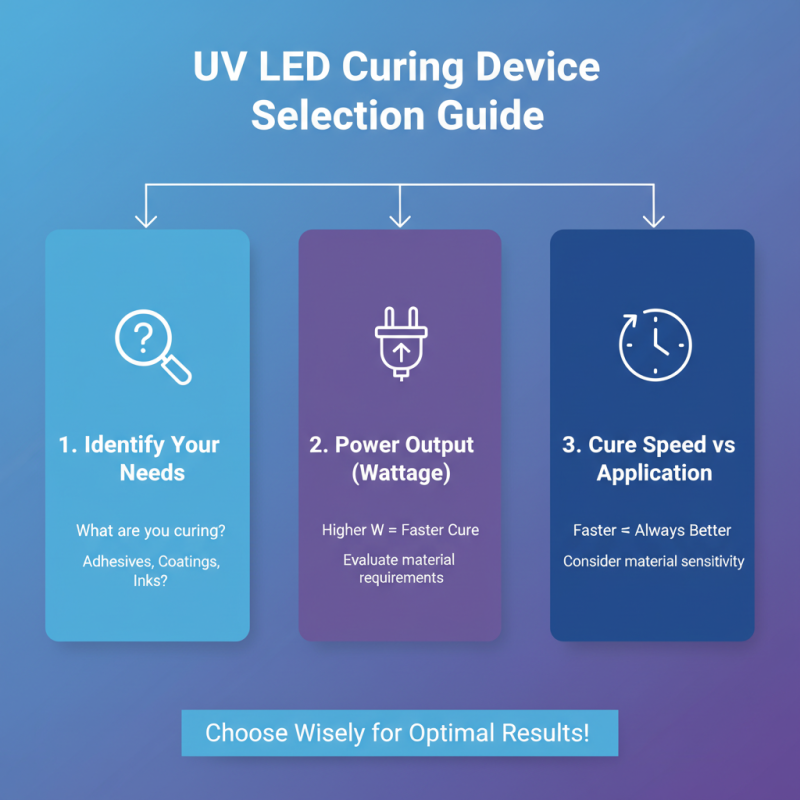

Tip: For optimal performance, consider the specific needs of your projects. Analyze the type of material you will be curing and match it with the right UV LED device. Testing various settings can help refine your process.

Still, not all UV LED devices deliver the promised results. Some may have inconsistent curing capabilities. This inconsistency can lead to defects in finished products. Users should remain mindful of the potential limitations, ensuring equipment matches requirements accurately before committing to large-scale use.

UV LED curing devices are essential tools in various industries. Selecting the right one can enhance efficiency and output quality. When considering a device, pay attention to its wattage. A higher wattage usually means faster curing times. This can save you valuable minutes in busy production settings.

Consider the size of the curing area too. If you work with larger materials, you need a sufficiently spacious curing unit. Some machines may seem compact but might restrict your workflow. Flexibility is a big plus; devices that accommodate different sizes can adapt to your varying project needs.

Tips: Look for adjustable settings. This feature allows you to modify curing times based on the material used, improving results. Also, check for overheating protection. Devices that lack this can pose risks, possibly leading to damage or safety concerns.

Also, review the lifespan of the LEDs. Some may fail faster than expected, leading to additional costs. Users often overlook this aspect until it's too late. Maintaining a budget for replacements is wise. Just because the upfront cost is low does not mean long-term expenses will follow suit. Always weigh your options carefully.

When exploring the top UV LED curing devices for 2026, several exceptional models stand out. They promise efficiency and durability, making them ideal for various applications. Each device comes with unique features. Some have adjustable settings to accommodate different projects. Others boast compact designs that enhance portability. However, not all models perform equally. Users may find varying levels of curing speed and effectiveness.

The layout of user interfaces can also differ between devices. Some models offer intuitive controls, while others may seem confusing at first glance. This inconsistency can lead to frustration during operation. Buyers should consider how user-friendly a model is before making a decision. Additionally, while many devices claim to provide superior results, not all live up to expectations. It’s essential to read reviews and weigh feedback from actual users.

Investing in a UV LED curing device may seem straightforward, but it requires careful consideration. The price range can be broad, which makes choosing the right option challenging. Prioritizing specific needs is crucial. Some might prioritize quick curing times, while others may seek versatility in their usage. Reflecting on these factors can help in making an informed decision. Ultimately, finding the best fit will enhance both the quality and efficiency of your projects.

When choosing a UV LED curing device, performance and efficiency are crucial. An efficient device cures materials quickly. However, not all units deliver high-quality results. Some may leave uncured spots or uneven finishes. This can be frustrating, especially when aiming for a professional look.

The comparative analysis reveals that the best devices maintain consistent output. They often feature adjustable settings for different materials. This adaptability is vital for users who work with various tasks. Additionally, energy consumption varies significantly. Efficient models can save costs over time. Some users report that cheaper units lack the necessary power, leading to wasted time.

It's important to consider the size and design of the curing device. Compact models might offer portability but can compromise power. Larger units, while powerful, may require more space. This balance is often overlooked. Reflection on personal needs can guide choices. Ultimately, testing devices may reveal their true capabilities. Practical experience is invaluable.

This chart presents the comparative performance of different UV LED curing devices based on their curing efficiency. Each device's efficiency is measured in percentage, showcasing their effectiveness in curing processes.

When choosing a UV LED curing device, consider your specific needs. Think about what you will be curing. Different devices have varied power outputs. A higher wattage often results in faster curing times. However, faster isn't always better for every application.

Next, check the size of the device. Some units are compact, while others are larger and more powerful. Compact devices are good for small projects. Larger devices might be overkill but beneficial for extensive work. The design and ease of use also matter. Some devices have user-friendly controls. That can save time while working.

Look into the wavelength of the UV light. Different materials require different wavelengths for effective curing. If unsure, consult product guidelines. It's essential to ensure compatibility with your materials. Lastly, pay attention to safety features. UV light can be harmful. Devices with smart safety measures can offer extra peace of mind. Always consider your work environment and safety protocols before making a decision.