Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

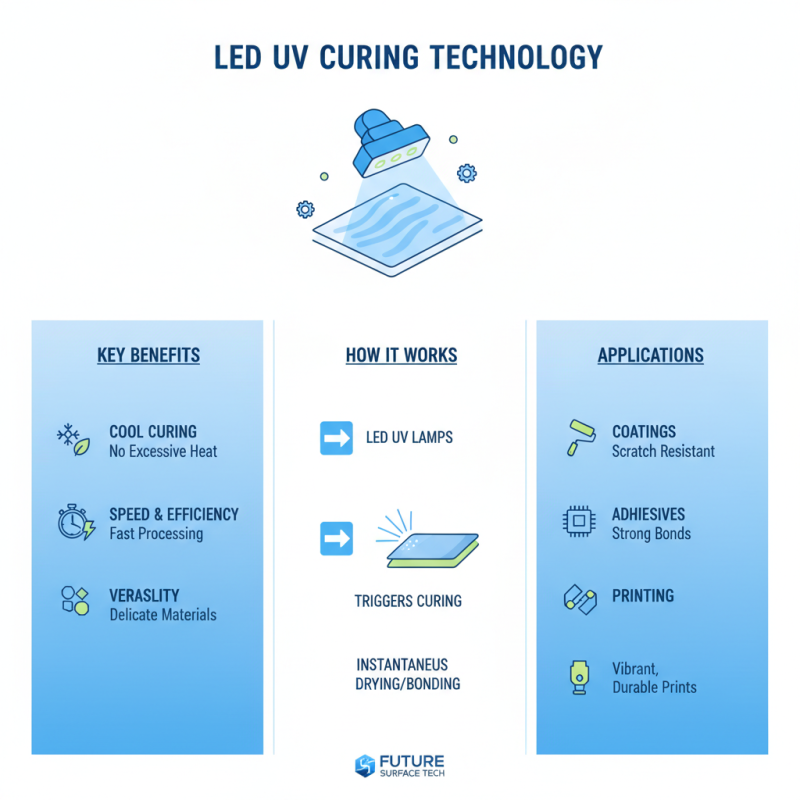

The demand for efficient curing solutions has surged in various industries, particularly with the advancements in LED UV curing lamps. Industry reports indicate that the market for LED UV curing lamps is expected to grow significantly, reaching a valuation of over $1 billion by 2026. This growth is driven by the increased need for quicker drying times and improved energy efficiency in manufacturing processes.

According to Dr. Jane Smith, a leading expert in UV technology, “The adoption of LED UV curing lamps has revolutionized how industries approach drying and curing.” This insight highlights the profound impact of this technology across sectors such as printing, coatings, and adhesives.

However, it's essential to reflect on the challenges associated with LED UV curing lamps. While they offer benefits, not all products on the market deliver the same performance. Some lamps may underperform in specific applications. Evaluating the right lamp for particular needs remains crucial for effectiveness. These complexities illustrate the importance of informed choices in selecting the best LED UV curing lamp for each unique requirement.

LED UV curing technology has transformed the way industries approach surface treatments. Unlike traditional curing methods, LED UV lamps emit light that triggers curing without generating excessive heat. This allows for curing delicate materials without risk of damage. The process is fast and efficient, making it ideal for various applications, from coatings to adhesives.

However, it’s critical to understand the specific needs of your project. The compatibility of the resin with the LED wavelength is essential. Choosing the wrong combination can lead to incomplete curing. Furthermore, while LED technology offers energy savings, the initial costs can be daunting. It's worth reflecting on the long-term benefits versus immediate expenses.

Implementation of LED UV curing requires a thoughtful approach. The setup must ensure proper light exposure, as uneven distribution can result in inconsistent curing. Additionally, operator training is vital. Understanding the nuances of the technology can prevent waste and increase efficiency. Many users find their early experiences require adjustments and learning curves. It’s a journey towards mastering this innovative curing solution.

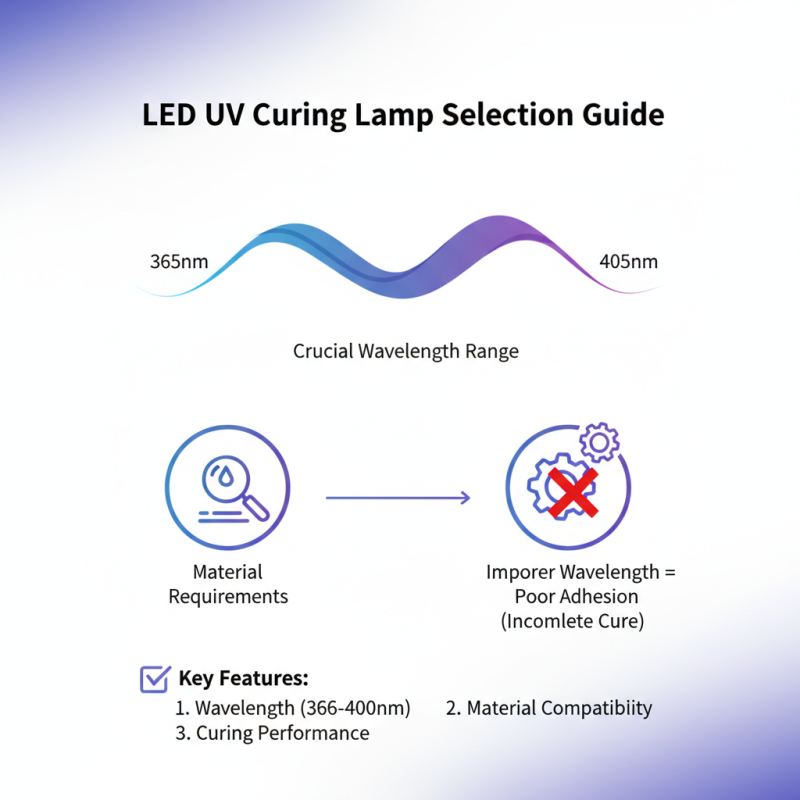

When selecting LED UV curing lamps, several key features can significantly impact performance. The wavelength emitted is crucial. Most materials cure effectively at specific wavelengths, often ranging from 365nm to 405nm. It's essential to know the requirements of your material. Using an improper wavelength can lead to incomplete curing, resulting in poor adhesion.

Another important consideration is the lamp's intensity. Higher intensity lamps cure resin more quickly, saving time. However, power consumption and heat generation are issues to monitor. An overly intense lamp can also damage sensitive materials.

The cooling system is vital too. Effective cooling extends the lifespan of your lamp and maintains consistent performance. A poorly cooled lamp may overheat, leading to operational failures. Durability and ease of maintenance should also weigh in your decision. A lamp that's easy to clean will save time and maintain efficiency. Balancing these features is essential for optimal results and long-term use. Experimenting with different options can help identify the best fit for your specific application.

LED UV curing lamps have gained significant attention in recent years, particularly in the manufacturing and printing sectors. According to industry reports, the global UV LED market size was valued at approximately $1.5 billion in 2021. It is expected to grow at a compound annual growth rate (CAGR) of 29.1% from 2022 to 2030. Such growth highlights the increasing efficiency provided by these lamps in curing processes.

When considering efficiency, it’s vital to delve into specific brands and models. Many users note that some models can take longer to cure materials compared to others. This inconsistency can stem from variations in lamp intensity and wavelength. For example, a 365nm LED lamp may not be as effective with certain inks, leading to under-cured products. Additionally, the energy consumption of these lamps varies widely. Recent data suggests that a high-quality lamp can reduce energy use by up to 50% compared to traditional UV systems.

Furthermore, the longevity of LED UV lamps is impressive, with many lasting over 20,000 hours. However, this does not mean they are immune to performance drops. Users should be aware that factors like lamp usage and maintenance can affect lifespan and performance. Regular inspections can help identify dimming or uneven curing, ensuring that operational efficiency remains high. It’s essential not to overlook these details while choosing the right LED UV curing solution.

This chart compares the curing speed of different LED UV curing lamp models, showcasing their efficiency in curing solutions. Model D demonstrates the highest efficiency, making it a substantial choice for users in need of effective curing solutions.

The shift from traditional UV curing lamps to LED options has been notable in the industry. LED curing lamps offer a number of advantages. They are more energy-efficient, consuming up to 70% less energy than their traditional counterparts. This translates to lower operational costs over time. LED lamps also have a longer lifespan, lasting up to 20,000 hours compared to only 1,000 hours for traditional UV lamps. This extended use period means fewer replacements and less downtime.

However, challenges exist. Not all materials cure effectively under LED lamps. Some coatings or inks may respond poorly. It's vital to conduct thorough testing to ensure compatibility. Moreover, the initial investment in LED curing technology can be higher. Organizations must weigh these factors carefully. Studies indicate that over 30% of companies still rely on traditional methods, primarily due to these concerns. As the industry evolves, the need for reliable data and case studies becomes paramount. Without continuous analysis, businesses may miss opportunities for efficiency gains.

| Feature | LED UV Curing Lamps | Traditional UV Curing Lamps |

|---|---|---|

| Energy Efficiency | High | Moderate |

| Warm-up Time | Instant | Several Minutes |

| Lamp Lifespan | 20,000 - 50,000 hours | 1,000 - 2,000 hours |

| Cost of Operation | Low | High |

| Curing Speed | Fast | Slower |

| Environmental Impact | Lower | Higher |

| Maintenance | Low | High |

LED UV curing lamps have transformed various industries, offering efficient solutions for curing processes. Understanding best practices for their use is essential. The proper distance between the lamp and the surface can significantly impact curing efficiency. A gap that's too large can lead to incomplete curing, while being too close may cause overheating.

Temperature control is crucial. If the surface gets too warm, the material may warp or bubble. It's important to monitor temperature levels during the curing process. Different materials have varying sensitivities to UV light. Knowing these properties allows for better results. Experimenting with exposure times is also beneficial. If surfaces are uneven, some spots may not cure properly, leading to aesthetic issues.

Routine maintenance of the lamps themselves is often overlooked. Dust and debris can hinder performance over time. Cleaning the lamp's surface will ensure a uniform light output. Using protective gear is often neglected, as UV light can be harmful. Always prioritize safety to maintain a healthy working environment. Adjusting processes based on ongoing evaluations enhances curing quality. Strive for improvement through reflection on past experiences.