Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

LED curing lamps are essential tools in modern dentistry and nail art. These devices provide efficient curing of light-sensitive materials, ensuring strong, durable results. However, achieving optimal performance may require careful consideration and proper technique.

Choosing the right LED curing lamp can impact your work significantly. Various models on the market offer different wavelengths and power outputs. Some may not deliver consistent results, leading to undercured materials. Users often overlook factors like bulb age and cleanliness. Regular maintenance is crucial for peak performance.

Consider light intensity and curing time, as these elements influence the final outcome. Yet, you may need to experiment with different settings. Adequate testing helps avoid costly mistakes. Many professionals benefit from sharing their experiences and learning from errors. Not every lamp is perfect, and discovering the right adjustments can enhance results.

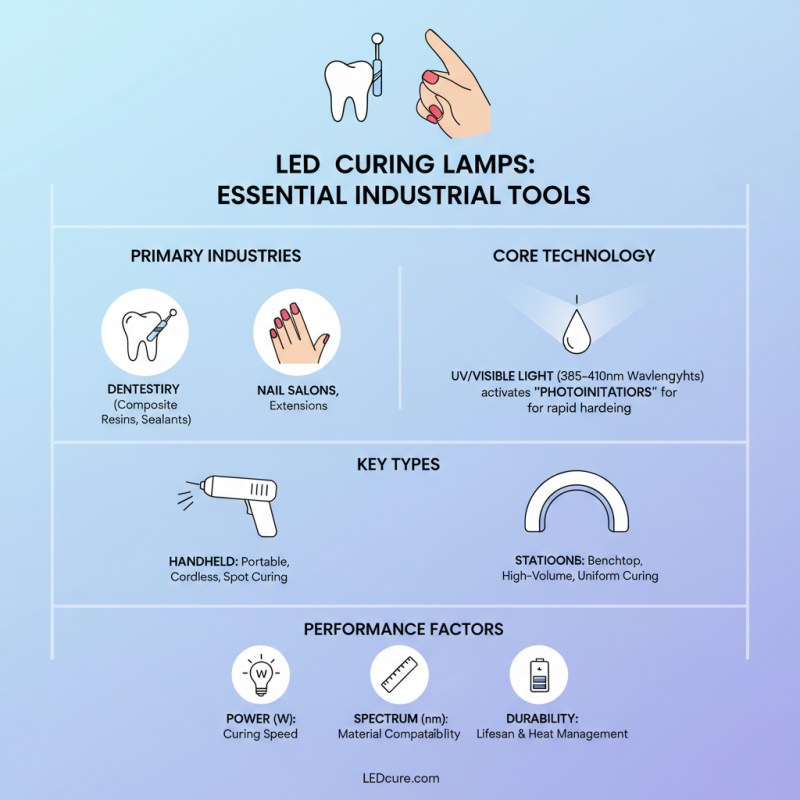

LED curing lamps are essential in various industries, primarily in dentistry and nail salons. These devices use specific wavelengths of light to cure materials like resins. Understanding their types and features can significantly enhance performance.

There are several types of LED curing lamps. For instance, some devices emit a narrow spectrum, specifically targeting certain photoinitiators. Others provide a broader light spectrum, accommodating a variety of materials. A recent report highlights that using a lamp with a multi-wavelength capability increases curing efficiency by up to 35%. Additionally, the power output is crucial; lamps with higher power can cure materials faster.

Features like timer settings and intensity adjustment also impact functionality. A lamp with adjustable intensity allows users to tailor the curing process. Studies reveal that optimal curing intensity can reduce the chances of over-curing, which leads to material brittleness. Moreover, the cooling mechanism in lamps plays a role in user comfort. Poorly designed cooling can lead to overheating, impacting performance. While many users prioritize speed, choosing the right lamp involves balancing speed with material integrity. This attention to detail is vital for optimal results.

When considering LED curing lamps, several key factors can greatly influence their performance. One significant aspect is the wavelength of the light emitted. Different materials cure best at specific wavelengths. If the wavelength does not match, the curing process may fail. Too often, users overlook this detail, leading to suboptimal results.

Another factor is the intensity of the LED light. Higher intensity can speed up the curing time. However, it's essential to balance intensity with potential overheating. Frequent overheating can damage materials or reduce lamp lifespan. Users must monitor this carefully. Experimentation often reveals that finding the right balance takes time and reflection.

Lastly, lamp positioning affects the curing outcome. If poorly positioned, light may not reach all areas evenly. This uneven curing creates weak spots, which are challenging to identify until later. It can be frustrating for users who expect consistent results. Adjusting positions and angles can help, but practice is necessary to perfect the technique.

This chart illustrates key factors influencing LED curing lamp performance, including wavelength, power output, curing time, heat generation, and durability. Each factor is essential for achieving optimal curing results.

Using LED curing lamps effectively requires attention to detail. Ensure that the lamp is positioned correctly. A direct angle will help cure the material evenly. Moving the lamp slowly can enhance outcomes. Avoid rushing this process, as it can lead to incomplete curing.

Pay attention to the recommended curing time for each material. Many practitioners overlook this. Too little time can leave the material soft. Conversely, excessive exposure can damage it. Keep an eye on the lamp’s intensity, as this varies by model and environment.

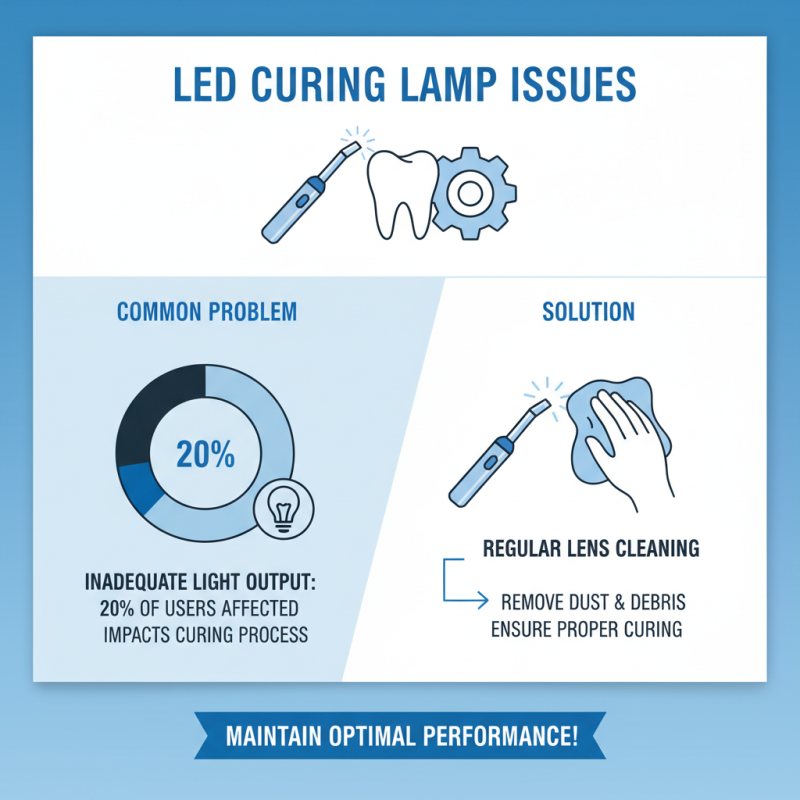

Regular maintenance of the lamp is crucial. Clean the light source often to ensure optimal performance. Dust and debris can reduce effectiveness. User habits should be analyzed. Take notes on how different techniques perform. Reflect on any inconsistencies that arise. Overall, practice and observation will lead to improved results.

Proper maintenance of LED curing lamps is crucial for extending their lifespan and ensuring optimal performance. Regular cleaning is essential. Dust and residue can build up, affecting light output. Use a soft, dry cloth to wipe the lamp's exterior and the lens. Avoid harsh chemicals that could damage the surface.

Temperature control is another key factor. LED lamps perform best within a certain temperature range. Extreme heat can cause overheating and premature failure. Allow the lamp to cool down after each use. Ensure that the workspace has adequate ventilation.

Additionally, replacing the bulbs when they begin to fade ensures consistency. Many lamps have indicators for bulb performance. Monitor the curing effectiveness regularly. If results differ, it may be time for replacements. Pay attention to any flickering or uneven curing. These signs often indicate that maintenance is required. Keeping a routine maintenance schedule helps prolong device life significantly.

LED curing lamps are essential for many dental and industrial applications. However, users often encounter issues that can hinder their performance. One of the most common problems is inadequate light output. Studies indicate that 20% of users experience this issue, impacting the curing process. It's crucial to regularly clean the lens. Dust and debris can block the light, preventing proper curing.

Another frequent concern is overheating. High temperatures can degrade the lamp and reduce its lifespan. Reports show that lamps operated beyond their optimal temperature range can fail prematurely, sometimes within six months. Regularly checking the cooling systems and ensuring proper ventilation can mitigate this risk.

Finally, inconsistent curing results can also arise from improper settings. Inadequate power settings lead to under-curing, while excessive power can overheat materials. It's important to refer to the material's guidelines and adjust the lamp accordingly. Regular calibration of lamps may help maintain consistent output. Users should not overlook these aspects, as small adjustments can significantly enhance performance.