Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

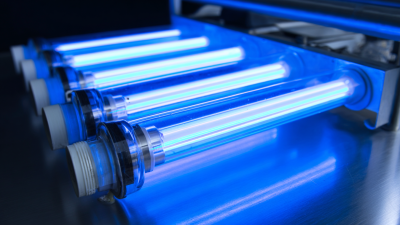

UV Drying Light technology has revolutionized curing applications across various industries. It uses ultraviolet light to dry and cure inks, coatings, and adhesives quickly. According to a report by Smithers Pira, the UV curing market is expected to reach $4.3 billion by 2025. This growth shows the increasing reliance on efficient curing solutions.

One key benefit of UV Drying Light is its speed. Traditional drying methods can take hours, while UV curing often occurs in seconds. This efficiency boosts productivity and reduces operational costs. However, some may overlook the nuances of proper application, which is crucial for optimal results. Understanding the right exposure times and power intensities is vital for achieving desired outcomes.

With a reduced carbon footprint, UV technology is also more environmentally friendly. Many companies are shifting toward UV curing methods to comply with stricter environmental regulations. However, the transition requires careful planning and investment. The benefits are clear, but challenges remain. As the industry evolves, ongoing improvements in UV Drying Light technology will pave the way for new opportunities.

UV drying light technology is transforming the curing process across various industries. This method utilizes ultraviolet light to cure or harden materials quickly. Such technology is prevalent in applications like printing, coatings, and adhesives. The benefits are tangible, particularly in improving production times and enhancing product quality.

Tips: When using UV lights, ensure a proper distance from the surface. Inconsistent distances may lead to uneven curing. It is essential to monitor the exposure time as well. Too little or too much can compromise the results.

Interestingly, many users may underestimate the importance of UV light's spectrum. Each material reacts differently to specific wavelengths. It can be a trial-and-error process. Understanding the right settings is crucial for optimal results, and failures in this area might lead to wasted materials.

Tips: Regularly inspect your UV light source for efficiency. Old bulbs can diminish effectiveness. Also, keep your workspace clean to avoid contamination that can cause defects.

UV drying technology plays a vital role in curing processes across various industries. One significant benefit is speed. Curing with UV light can dramatically reduce the time needed for products to harden. This swift process allows for higher production rates, meeting demanding schedules more efficiently.

Another key advantage lies in energy efficiency. UV drying systems often consume less energy compared to traditional methods. This reduction can lead to lower operational costs. It’s also environmentally friendly, as it reduces the need for solvents. However, it’s essential to ensure proper safety measures. UV radiation can pose risks if not handled correctly.

Uniformity in curing is another major selling point. UV light provides even coverage, preventing inconsistencies in the final product. Yet, certain materials may not respond well to UV light. Manufacturers should conduct tests to ensure compatibility. Not every application is suited for UV drying, so careful consideration is necessary.

The effectiveness of UV curing is clear. It significantly speeds up the curing process. Traditional methods can take hours. In contrast, UV drying light cures materials in minutes. This rapid transformation increases productivity. Manufacturers can meet tight deadlines more easily.

Another advantage is the energy efficiency of UV lights. They consume less power than conventional drying methods. This can lead to lower operational costs. However, the energy savings can vary. It’s essential to assess each application carefully. Not every setup maximizes these benefits.

The technology also offers consistency in results. UV curing provides uniform finishes on surfaces. This can be crucial for high-quality standards. Yet, there are considerations. Not all materials respond well to UV light. Users must experiment to find the right match. Some may need adjustments in settings or setups. This trial-and-error could enhance overall output.

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Faster Curing Time | UV drying lights cure materials much quicker than traditional methods. | Reduces overall production cycles. |

| Energy Efficiency | Less energy consumption compared to heat curing systems. | Lower energy bills and reduced carbon footprint. |

| Consistent Results | UV curing provides uniform curing across materials. | Improves overall product quality. |

| Reduced Warping | Minimized thermal exposure prevents warping of materials. | Enhances product durability. |

| Versatility | Compatible with a wide range of substrates and coatings. | Broadens application possibilities. |

| Space Saving | Compact systems can easily fit in smaller workspaces. | Optimizes factory floor space usage. |

| Safe Operation | Non-heat curing prevents scorching and burning hazards. | Improves safety in the workplace. |

| Environmentally Friendly | Fewer VOC emissions compared to solvent-based products. | Supports sustainable production practices. |

| Minimal Maintenance | Low maintenance requirements lead to lower costs. | Increases productivity uptime. |

| Cost-Effectiveness | Initial investment is offset by savings in time and materials. | Enhances overall profitability. |

The reduction of volatile organic compounds (VOCs) is a key benefit of UV drying light technology in curing applications. Traditional curing methods often rely on solvents, releasing harmful VOCs into the environment. According to a report by the Environmental Protection Agency, VOC emissions from industrial processes can contribute to air pollution and health issues.

UV drying systems emit minimal VOCs, drastically lowering harmful emissions. A study by the National Institute of Standards and Technology highlighted that UV curing can reduce VOC levels by up to 90%. This is significant for industries seeking to enhance sustainability and comply with stricter regulations. Factory managers are increasingly aware of their environmental footprint.

However, transitioning to UV curing isn't without challenges. Initial setup costs can be high. Furthermore, not all materials are suitable for UV curing. This lack of compatibility may deter some manufacturers. It's essential to evaluate the long-term savings against these initial hurdles. While the benefits are clear, the path to full adoption requires careful consideration.

This chart illustrates the key benefits of using UV drying light in curing applications, focusing on the reduction of volatile organic compounds (VOCs) and other advantages associated with UV technology.

UV drying technology plays a key role in various industries today. Its versatility makes it a valuable process for curing applications. According to a recent report, the global UV curing market is expected to reach $3.5 billion by 2025. This growth can be attributed to its increasing adoption across sectors like automotive, electronics, and packaging.

In the automotive industry, UV curing is essential for coatings and adhesives. It allows for faster production rates. Many manufacturers see a 50% reduction in curing times. This boost in efficiency shortens lead times. In the packaging sector, UV drying enhances printing quality. With a nearly 30% rise in demand for UV-printed materials, brands are leveraging this technology to improve durability.

However, not every application benefits equally. Some materials may not respond well to UV light. This limitation necessitates careful selection and testing. Manufacturers must also consider energy consumption and environmental impact. While UV drying reduces volatile organic compounds (VOCs) significantly, the initial equipment costs can be high. These factors require ongoing evaluation to maximize ROI in curing processes.