Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

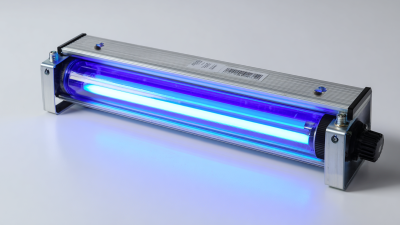

In recent years, the manufacturing and printing industries have increasingly embraced advanced technologies to improve efficiency and productivity. One significant innovation that has gained traction is the use of UV Curing Flood Lamps. According to a report by market research firm Research and Markets, the UV curing market is projected to reach USD 3.38 billion by 2026, highlighting the growing reliance on UV curing solutions across various applications. This surge is driven by the need for faster curing times, reduced energy consumption, and the ability to achieve high-quality finishes.

UV Curing Flood Lamps offer numerous advantages over traditional curing methods, significantly enhancing curing efficiency. These lamps emit UV light that rapidly polymerizes inks, coatings, and adhesives, reducing curing times from hours to mere seconds. Moreover, their ability to produce a consistent output over a large area ensures uniform curing, making them an ideal choice for high-volume production environments. Furthermore, industry reports suggest that the adoption of UV curing technologies can lead to a 30-50% reduction in energy usage, underscoring their environmentally friendly credentials. In this article, we will delve into the top seven benefits of using UV Curing Flood Lamps, providing valuable insights for businesses looking to optimize their curing processes.

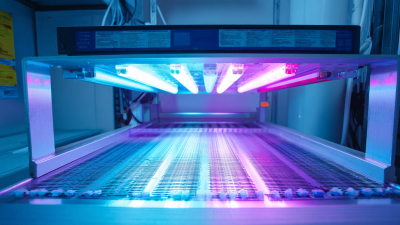

UV curing flood lamps are revolutionizing the curing process across various industries by significantly reducing curing times. According to the Radtech North America report, implementing UV technology can decrease production time by as much as 50%. This rapid curing not only accelerates manufacturing cycles but also enhances throughput, enabling businesses to meet increasing demand without compromising quality.

One primary advantage of UV curing flood lamps is their ability to achieve immediate curing upon exposure to ultraviolet light. This instantaneous reaction is particularly valuable in high-volume production settings, where traditional curing methods can take hours, leading to bottlenecks. The American Coatings Association indicated that using UV curing technology can improve the efficiency of volume production lines, thereby optimizing resource allocation and minimizing energy consumption. As companies strive for more sustainable practices, the energy efficiency of UV curing processes emerges as a crucial benefit, aligning with the industry's shift towards greener production methods.

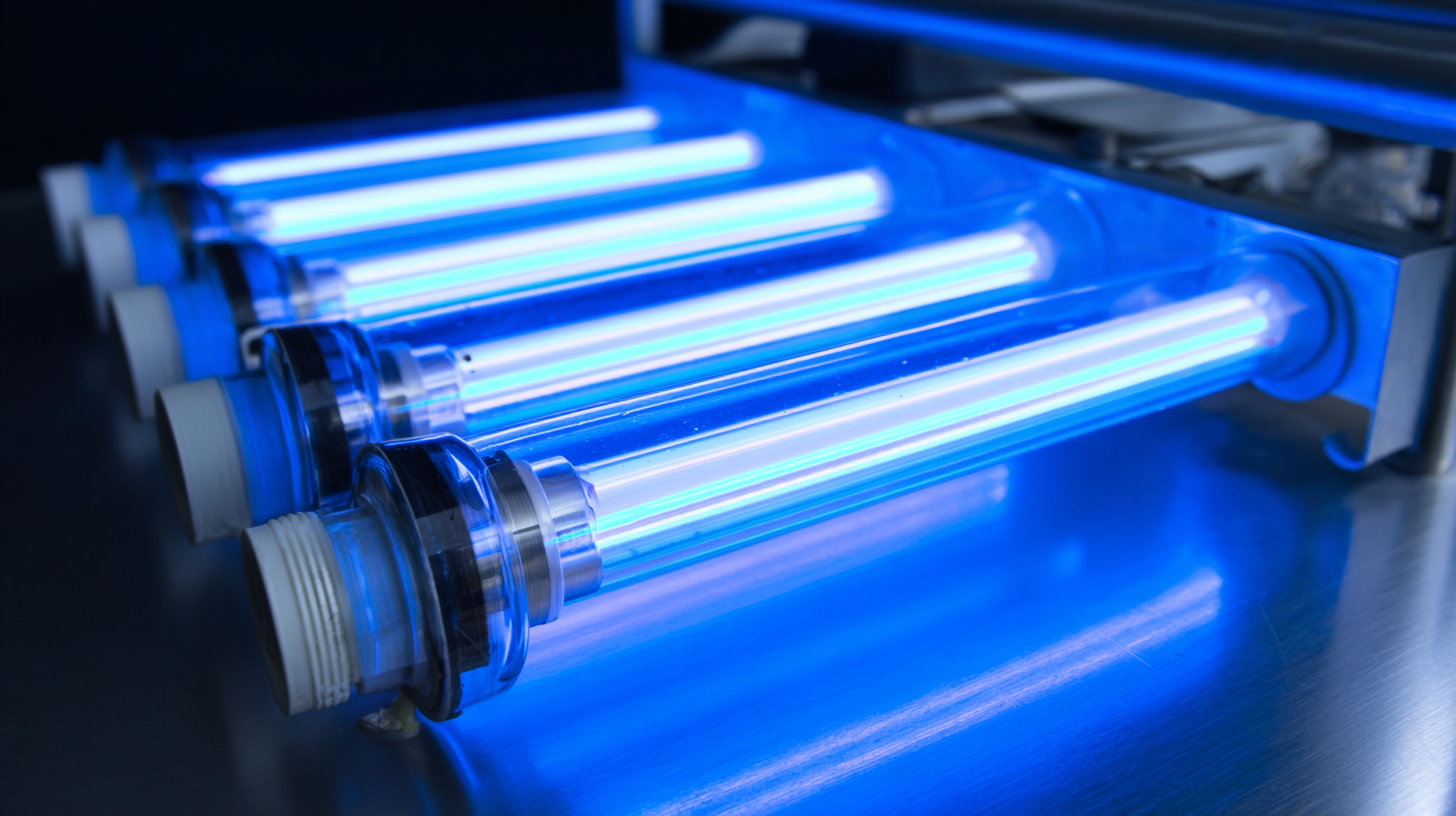

The utilization of UV curing technology has revolutionized various industries through improved energy efficiency. By harnessing the power of ultraviolet light, UV curing flood lamps significantly reduce the curing time compared to traditional methods, leading to faster production cycles. This efficiency not only enhances output but also conserves energy, making it an environmentally friendly option. Manufacturers can achieve optimal curing results with reduced power consumption, translating to lower operational costs and less strain on energy resources.

Moreover, UV curing systems produce minimal waste heat and require less auxiliary cooling, further improving their energy profile. The targeted nature of UV radiation means that only the required areas are cured, enhancing precision and minimizing energy loss. As industries increasingly focus on sustainability, the transition to UV curing technology presents a compelling case for businesses looking to optimize their processes while reducing their environmental footprint. By integrating this cutting-edge technology, companies can enhance product quality and contribute to a more sustainable future.

UV curing flood lamps are increasingly popular across various industries due to their versatility and efficiency in curing different materials. These lamps effectively cure inks, coatings, adhesives, and even some plastics, making them an essential tool for manufacturers and artisans alike. Their ability to provide uniform UV exposure over large areas ensures consistent results, reducing the risk of defects and enhancing overall product quality.

UV curing flood lamps are increasingly popular across various industries due to their versatility and efficiency in curing different materials. These lamps effectively cure inks, coatings, adhesives, and even some plastics, making them an essential tool for manufacturers and artisans alike. Their ability to provide uniform UV exposure over large areas ensures consistent results, reducing the risk of defects and enhancing overall product quality.

When using UV curing flood lamps, consider the specific material requirements and adjust exposure times accordingly. Different substrates may react differently, so running small tests first can help determine the optimal settings. Additionally, ensure proper safety measures are in place, such as protective eyewear and ventilation, to guarantee a safe working environment.

For maximum efficiency, position the flood lamp at the correct distance from the material to avoid overheating or under-curing. Experimenting with various angles and distances can also yield better results. By harnessing the benefits of UV curing flood lamps, you can achieve quicker turnaround times while maintaining high standards of quality in your products.

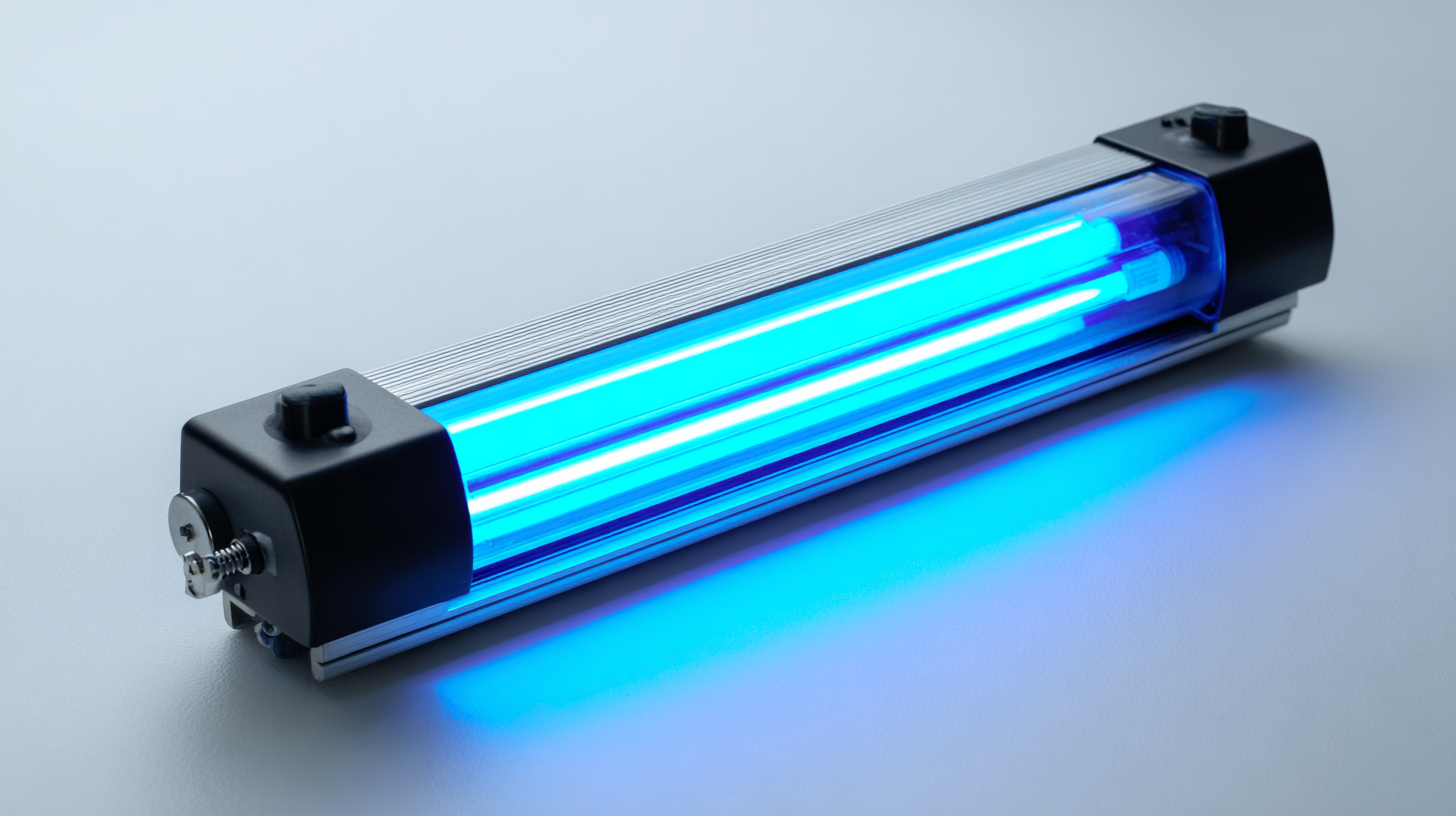

The use of UV curing flood lamps significantly enhances the finish quality of coated surfaces through uniform UV exposure. According to a study by the American Coatings Association, consistent UV exposure can reduce curing time by up to 50%, allowing for quicker processing without compromising the quality of the finish. This rapid curing process leads to stronger adhesion and improved durability of the coatings, as the uniform distribution of UV light ensures that every part of the surface is effectively cured.

Moreover, the benefits of enhanced finish quality extend to aesthetics as well. A report by the Industrial Coating Association indicates that applications utilizing UV flood lamps exhibit superior clarity and gloss, attributed to the lack of uneven curing that can result from traditional light sources. The ability to achieve a high-quality finish not only improves the product's visual appeal but also increases its resistance to chemical and environmental damage, ultimately extending the longevity of the coated items. As industries continue to prioritize efficiency and quality, UV curing flood lamps stand out as a vital technology for achieving optimal results.

The adoption of UV curing flood lamps can significantly enhance production speed and efficiency, leading to substantial cost savings for businesses in various industries. According to a report by the UV & EB Technology Association, manufacturers utilizing UV curing technology have reported an increase in curing speed of up to 40%. This boost allows for quicker turnaround times, enabling companies to fulfill orders faster and increase throughput without compromising product quality.

Moreover, the reduction in energy consumption compared to traditional curing methods contributes to lower operational costs. A study from the Industrial Technology Research Institute noted that UV curing systems can reduce energy use by as much as 60% during the curing process. This improvement not only decreases utility bills but also aligns with the growing trend towards sustainable manufacturing practices. By investing in UV curing flood lamps, companies not only enhance their production capacity but also achieve a competitive edge in the market through improved efficiency and lower overhead costs.