Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

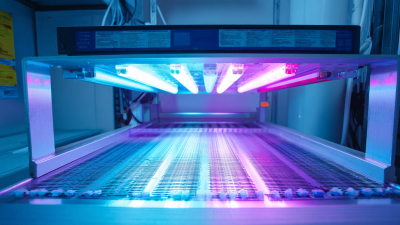

In recent years, the industrial sector has witnessed a significant shift towards the adoption of advanced technologies to enhance efficiency and productivity. One such innovation is the utilization of Uv Lamp High Power, which has emerged as a pivotal tool across various applications, including curing, sterilization, and disinfection processes.

According to a report by ResearchAndMarkets, the global UV lamp market is projected to reach $3.5 billion by 2025, driven by increasing demand in industries such as automotive, healthcare, and food safety. These high-power UV lamps offer rapid curing times and improved energy efficiency, reducing operational costs while delivering superior performance.

As businesses continue to seek ways to optimize their operations, understanding the myriad benefits of high-power UV lamps will be essential for staying competitive in the ever-evolving industrial landscape.

High power UV lamps have rapidly gained attention in various industrial processes due to their remarkable advantages. One prominent application is in food safety, where UV-C light is utilized for the microbial disinfection of beverages and dairy products. Recent studies indicate that UV-C irradiation effectively reduces pathogens, ensuring the safety and quality of food items while prolonging shelf life. The wavelength range of 200–280 nm proves to be particularly effective, enhancing the health benefits perceived by consumers of premium dairy and juice products.

High power UV lamps have rapidly gained attention in various industrial processes due to their remarkable advantages. One prominent application is in food safety, where UV-C light is utilized for the microbial disinfection of beverages and dairy products. Recent studies indicate that UV-C irradiation effectively reduces pathogens, ensuring the safety and quality of food items while prolonging shelf life. The wavelength range of 200–280 nm proves to be particularly effective, enhancing the health benefits perceived by consumers of premium dairy and juice products.

Another significant advantage of high power UV lamps lies in their application in wastewater treatment. The advancements in UV disinfection technology have bolstered sustainability efforts by promoting water reuse and recycling. Moreover, pulsed UV curing systems are also emerging, enabling efficient curing of medical devices while avoiding damage from excessive heat. This versatility exemplifies the capability of UV lamps to cater to diverse industrial needs.

Tips:

- When considering UV technology for your operations, ensure the selected wavelength targets the specific microorganisms of concern.

- Regular maintenance of UV lamps can enhance their efficiency and longevity, ultimately maximizing your investment.

High-power UV lamps have become integral to various industrial applications, particularly in sectors such as manufacturing, healthcare, and water treatment. These lamps, which emit ultraviolet light with significant intensity, are primarily utilized for curing materials like inks and coatings. According to a report by MarketsandMarkets, the global UV curing systems market size is projected to reach $4.7 billion by 2026, growing at a CAGR of 10.1%. This growth is driven by innovations in UV technology that enhance efficiency, contribute to faster production times, and reduce energy consumption.

In the realm of healthcare, high-power UV lamps play a crucial role in disinfection and sterilization processes. A study published in the Journal of Applied Microbiology highlighted that UV-C light, particularly at 254 nm, can inactivate up to 99.9% of pathogens within seconds. This effectiveness has led to a surge in the adoption of UV disinfection systems in hospitals and public spaces, especially in the wake of increased hygiene awareness due to recent global health events. Overall, the versatility and efficacy of high-power UV lamps are paving the way for enhanced operational efficiencies across these diverse industrial sectors.

The rise of high power UV lamps is transforming industrial applications, offering substantial advantages over traditional lighting. According to a report by the Global Lighting Association, high power UV lamps consume up to 80% less energy than conventional incandescent or fluorescent lights, leading to significant cost savings. These UV lamps emit concentrated light that is effective for processes such as curing, sterilization, and printing, making them indispensable in industries like manufacturing and healthcare.

Moreover, high power UV lamps boast a longer lifespan, often exceeding 20,000 hours compared to the typical 1,000 to 2,000 hours of traditional bulbs. This longevity translates to reduced maintenance costs and decreased downtime for businesses. A study from the International UV Association indicates that transitioning to high power UV technologies can improve operational efficiency by up to 50%, particularly in curing applications where rapid drying is essential. As industries seek sustainable and efficient lighting solutions, high power UV lamps are proving to be a superior choice, reshaping the landscape of industrial lighting.

| Parameter | High Power UV Lamps | Traditional Lighting |

|---|---|---|

| Energy Efficiency | 90% | 60% |

| Lifespan (Hours) | 15,000 | 2,000 |

| Speed of Curing | Instant | Minutes |

| Heat Generation | Low | High |

| Safety (UV Radiation) | Requires Protective Measures | Generally Safe |

| Application Versatility | High | Moderate |

When utilizing high power UV lamps in industrial applications, safety considerations are paramount. According to the International Society for Optics and Photonics, exposure to UV light can pose serious health risks, including skin burns and eye damage. The American National Standards Institute (ANSI) sets forth guidelines that recommend protective equipment, such as UV-blocking goggles and full-body clothing, to mitigate these risks. Industries using UV technology for sterilization or curing processes must implement comprehensive safety protocols to ensure worker protection.

Best practices for UV lamp usage also involve regular maintenance and monitoring. The Radiation Safety Committee suggests routine inspections of UV lamps to ensure they are operating within safe intensity levels, as overexposure can lead to both safety hazards and equipment degradation. Additionally, proper signage should be displayed in work areas to alert personnel to potential hazards. Implementing a training program for employees on the correct handling and operational procedures of UV lamps not only promotes safety but also enhances the efficiency of industrial processes, ensuring a safe workplace while maximizing the benefits of UV technology.

The landscape of high power UV technology is rapidly evolving, driven by advancements in materials and engineering. Industries are increasingly recognizing the efficiency and effectiveness of high power UV lamps in applications such as curing, disinfection, and precision processing. These lamps offer not only faster curing times but also a reduction in energy consumption compared to traditional methods. As manufacturers innovate, we are seeing the development of UV lamps that provide longer lifespans and enhanced performance, which directly translates to cost savings for businesses.

Looking ahead, the future trends in high power UV technology point towards greater integration with automation and smart technologies. The emergence of IoT (Internet of Things) will allow for more precise control and monitoring of UV systems, leading to improved operational efficiencies. Additionally, as industries place a stronger emphasis on sustainability, there is a growing trend towards eco-friendly UV solutions that minimize environmental impact. The ability to seamlessly incorporate UV technology with existing manufacturing processes will likely shape the next wave of industrial advancements, catalyzing an era where high power UV solutions become crucial for competitiveness in the market.