Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In recent years, the adoption of UV Curing Flood Lamps has reshaped various industrial processes, driving significant improvements in efficiency and quality. According to a report by MarketsandMarkets, the UV curing market is projected to reach USD 5.4 billion by 2026, growing at a CAGR of 8.4% from 2021. This surge in demand is largely attributed to the unique capabilities of UV curing technology, which allows for rapid curing of coatings and inks, enhancing production speeds without compromising product integrity.

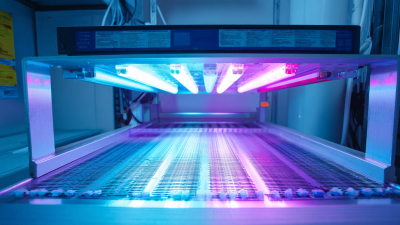

The ability to cure large areas uniformly makes the UV Curing Flood Lamp an essential tool in sectors such as automotive, electronics, and woodworking. As manufacturers seek innovative solutions to meet increasing consumer demands and regulatory standards, the exploration of diverse applications for UV Curing Flood Lamps signifies a new era in enhancing industrial efficiency and sustainability.

Ultra-Violet (UV) curing technology has emerged as a cornerstone in various industrial applications, transforming how products are manufactured and finished. This technology utilizes UV light to rapidly cure or harden coatings, inks, and adhesives, significantly enhancing efficiency. According to a report by MarketsandMarkets, the UV curing market is projected to grow from USD 2.8 billion in 2020 to USD 4.8 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.5%. This growth is fueled by the increasing demand for environmentally friendly solutions that reduce VOC emissions and offer faster production cycles.

The fundamentals of UV curing hinge on photopolymerization, where UV light initiates a chemical reaction that quickly solidifies the material. This technology is widely adopted in industries such as printing, woodworking, and electronics. For instance, in the printing sector, UV inks enable immediate handling after printing, improving workflow efficiency. A study by the Adhesive and Sealant Council found that UV-cured adhesives demonstrate superior bonding strength and chemical resistance, making them indispensable for applications requiring durability. The innovation in UV curing lamps, such as flood lamps that cover larger areas, enhances operational efficiency, allowing manufacturers to meet the ever-increasing demand for rapid production cycles.

The advent of UV curing flood lamps is revolutionizing the industrial landscape by significantly enhancing production efficiency. These advanced lamps utilize ultraviolet light to rapidly cure coatings, inks, and adhesives, making them invaluable in various manufacturing processes. By reducing drying times from hours to mere seconds, businesses can streamline operations, increase throughput, and ultimately boost profitability. Moreover, the controlled application of UV light minimizes waste, supporting both sustainability goals and cost reduction.

The advent of UV curing flood lamps is revolutionizing the industrial landscape by significantly enhancing production efficiency. These advanced lamps utilize ultraviolet light to rapidly cure coatings, inks, and adhesives, making them invaluable in various manufacturing processes. By reducing drying times from hours to mere seconds, businesses can streamline operations, increase throughput, and ultimately boost profitability. Moreover, the controlled application of UV light minimizes waste, supporting both sustainability goals and cost reduction.

Tip: When integrating UV curing flood lamps, ensure that your workspace is equipped with appropriate safety features, such as UV shields and protective eyewear, as prolonged exposure can pose health risks.

In addition to speed, UV curing flood lamps offer superior quality finishes. Unlike traditional curing methods, which may lead to uneven results, UV lamps provide consistent and uniform curing, enhancing the durability and appearance of finished products. Industries ranging from automotive to electronics are reaping these benefits, translating to heightened customer satisfaction and loyalty.

Tip: Regularly maintain and calibrate your UV curing equipment to ensure optimal performance and consistent results across production runs, reducing downtime and unexpected quality issues.

Industries across the globe are increasingly adopting UV curing flood lamps, showcasing significant advancements in operational efficiency and product quality. A notable case study in the automotive sector illustrates how a leading manufacturer reduced curing times by 50%, thereby increasing production rates by 30%. This shift not only improved throughput but also minimized energy consumption, allowing for a more sustainable production cycle. According to a recent market research report, the UV curing market is projected to reach $5.4 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.2%.

In the packaging industry, a prominent beverage company successfully implemented UV curing technology to enhance label adhesion without compromising production speed. This transition resulted in a 25% reduction in waste materials and improved the overall aesthetic quality of their products. Similarly, the electronics field leverages UV curing to secure components and coatings, elevating both performance and durability. As per industry data, around 45% of electronic manufacturers are incorporating UV curing processes to enhance efficiency.

Tips: When considering the implementation of UV curing flood lamps, evaluate the specific needs of your production line to select the appropriate intensity and wavelength for optimal results. Additionally, ensure proper training for your team to fully exploit the benefits of this technology, enhancing both safety and operational knowledge. Lastly, regularly monitor the curing process to maintain high-quality standards and minimize defects.

When selecting the right UV curing flood lamp for your specific needs, it's essential to consider several key factors that will enhance your industrial efficiency. First and foremost, the wavelength of the lamp plays a crucial role in its effectiveness. Different materials and coatings cure optimally at various wavelengths, so understanding the compatibility of your substrate with the lamp's output is vital.

Moreover, a deep dive into the curing speed can help you gauge the efficiency of the lamp; faster curing times can significantly reduce production bottlenecks.

Another important criterion is the lamp's intensity and coverage area. A higher intensity lamp can offer quicker cures but may require more precise alignment to cover larger areas adequately. Therefore, understanding the scale of your application will help in choosing a lamp with the right intensity and output pattern. Additionally, look for features like energy efficiency and ergonomic design, which contribute to lower operational costs and ease of use.

Taking the time to evaluate these factors will ensure that you select a UV curing flood lamp that meets your specific industrial requirements and contributes to a more efficient production process.

The integration of UV curing technologies in manufacturing processes heralds a new era of industrial efficiency and sustainability. As industries seek to enhance productivity while minimizing environmental impact, UV curing flood lamps have emerged as a leading solution. This technology utilizes ultraviolet light to rapidly cure inks, coatings, and adhesives, optimizing production time and reducing the energy required for drying. With the UV curing system market projected to reach USD 23.47 billion, it is evident that businesses are recognizing the potential for significant operational improvements.

To successfully implement UV curing solutions, manufacturers should adhere to best practices that maximize efficiency and effectiveness. Understanding the intricacies of this technology, such as optimal lamp positioning, wavelength selection, and curing duration, can significantly influence the final product quality. Additionally, investing in proper ink management systems enhances both the efficiency of the printing process and environmental sustainability, enabling companies to reduce waste and emissions. By strategically adopting UV curing technology, manufacturers can not only streamline their operations but also contribute to a cleaner and more sustainable industrial landscape.

| Application | Industry | Efficiency Gain (%) | Curing Time Reduction (%) | Best Practices |

|---|---|---|---|---|

| Coatings and Finishes | Manufacturing | 30 | 50 | Maintain optimal lamp distance |

| Ink Curing | Printing | 25 | 40 | Use proper UV ink type |

| Adhesives | Construction | 20 | 60 | Ensure surface cleanliness |

| Optical Products | Electronics | 35 | 45 | Control the UV exposure time |

| 3D Printing | Additive Manufacturing | 40 | 70 | Optimize layer thickness |