Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

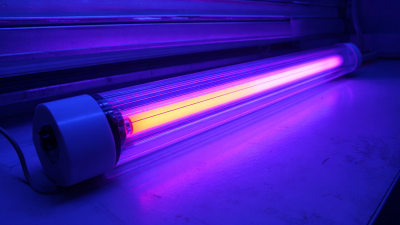

The innovation of UV glue curing lamps has revolutionized adhesive bonding techniques across various industries, enhancing efficiency and effectiveness in applications ranging from electronics to woodworking. According to a recent report by the Adhesive and Sealant Council, the global adhesive market is projected to reach $50 billion by 2025, with UV-curable adhesives gaining traction due to their rapid curing times and superior bond strength. These lamps not only speed up production processes but also reduce the need for energy-intensive curing ovens, contributing to a more sustainable manufacturing approach. As highlighted in market analyses, the adoption of UV glue curing lamps is expected to increase by over 20% annually, driven by the rising demand for high-performance adhesives in automotive, aerospace, and medical sectors. This paper explores the advantages of UV glue curing lamps, emphasizing their role in improving adhesive bonding techniques and meeting modern manufacturing demands.

UV glue curing lamps have transformed modern adhesive bonding techniques by offering numerous advantages that enhance both efficiency and effectiveness. One of the primary benefits is the rapid curing time. Traditional adhesives often require extended periods to set, which can lead to delays in production and increased labor costs. In contrast, UV curing technology enables adhesives to bond almost instantaneously when exposed to ultraviolet light, significantly speeding up manufacturing processes and allowing for quicker project completions.

Moreover, UV glue curing lamps provide superior bond strength and durability. The curing process results in a robust and resilient adhesive bond that is resistant to environmental factors such as moisture and temperature variations. This is particularly advantageous in industries that demand high-performance bonds, such as automotive, electronics, and construction. Additionally, UV curing systems are environmentally friendly, producing minimal volatile organic compounds (VOCs) compared to traditional bonding agents. As businesses increasingly prioritize sustainability, adopting UV glue curing techniques aligns with eco-friendly practices while maintaining high-quality standards in adhesive bonding.

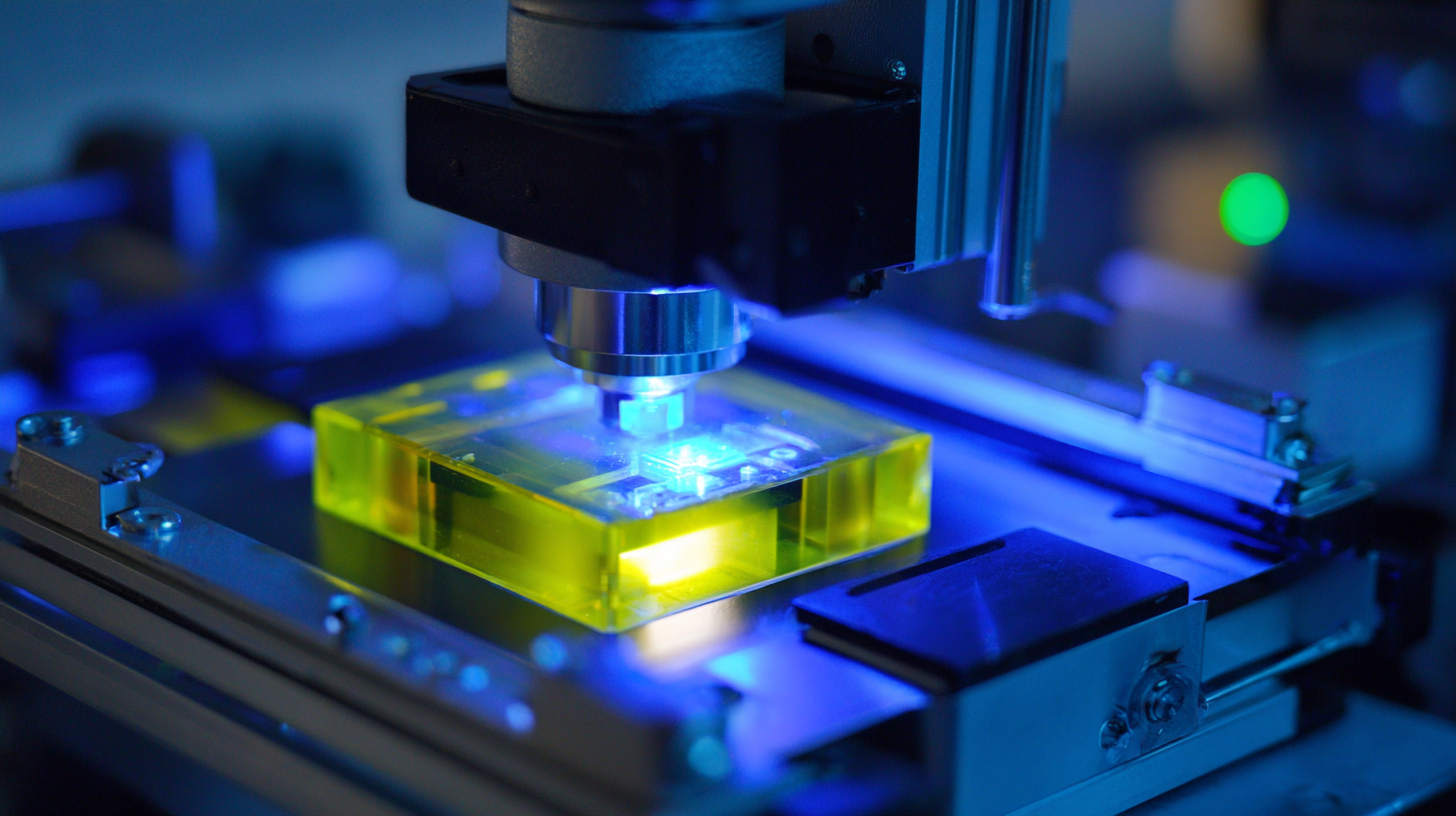

The mechanism of UV glue curing plays a crucial role in optimizing adhesive performance. UV curing involves the use of ultraviolet light to initiate polymerization reactions in adhesive formulations, leading to rapid and effective bonding. This technology not only enhances the curing speed but also allows for precise control over the adhesives' properties. Recent advancements in UV-curable adhesives, such as the modification of extruded polystyrene foams, showcase how hydrophobic treatments can improve interfacial bonding with materials like mortar. By enhancing the surface characteristics, these adhesives promote stronger and more durable connections.

Tips for effective UV glue curing include ensuring proper exposure to UV light and maintaining an appropriate curing environment. It is essential to select adhesives specifically formulated for UV curing, as they can provide superior performance in various applications. Furthermore, understanding the adhesive's chemical composition and optimizing curing cycles through kinetic analyses can significantly improve bonding results. Monitoring these details allows for reliable and efficient processes that meet demanding industrial standards, ultimately leading to increased product longevity and performance.

| Parameter | Description | Value |

|---|---|---|

| Wavelength Range | The optimal wavelength range for UV curing | 320 - 450 nm |

| Curing Speed | Speed at which the adhesive cures under UV light | 1 to 10 seconds |

| Bond Strength | Measuring the strength of the bonded joint | Up to 3500 psi |

| Durability | Resistance to environmental conditions | Excellent, 100% waterproof |

| Viscosity | The thickness of the adhesive before curing | 100 to 500 cP |

| Temperature Resistance | Ability to withstand high temperatures post-curing | Up to 120°C |

| Application Areas | Industries where UV adhesive bonding is utilized | Electronics, Automotive, Medical Devices |

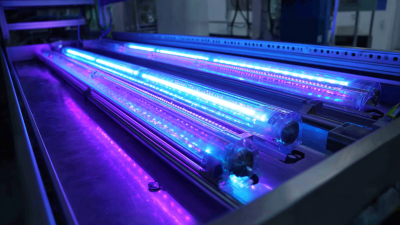

UV curing technology has increasingly gained traction as an efficient alternative to traditional adhesive techniques. Unlike conventional methods, which rely on heat or moisture for curing, UV curing utilizes ultraviolet light to instantly harden adhesives upon exposure. According to a report by Technavio, the global UV adhesives market is projected to grow at a CAGR of over 8% from 2021 to 2025, demonstrating a significant shift towards this innovative bonding technique.

UV curing technology has increasingly gained traction as an efficient alternative to traditional adhesive techniques. Unlike conventional methods, which rely on heat or moisture for curing, UV curing utilizes ultraviolet light to instantly harden adhesives upon exposure. According to a report by Technavio, the global UV adhesives market is projected to grow at a CAGR of over 8% from 2021 to 2025, demonstrating a significant shift towards this innovative bonding technique.

One of the primary advantages of UV curing is the speed of the bonding process. Traditional adhesives often require extended drying times, which can slow down production and increase labor costs. In contrast, UV adhesive curing can take just a few seconds, allowing manufacturers to improve throughput and efficiency. A study by the Adhesive and Sealant Council (ASC) highlighted that companies adopting UV technology have reported a 30% reduction in assembly time, underscoring its effectiveness for high-volume production environments.

Tips: For optimal results with UV curing, ensure that the adhesive is specifically formulated for UV light. Additionally, consider the distance of the UV lamp from the workpiece; maintaining an appropriate distance can enhance bonding effectiveness. Lastly, invest in quality UV lamps, as their intensity significantly affects curing speed and adhesive performance.

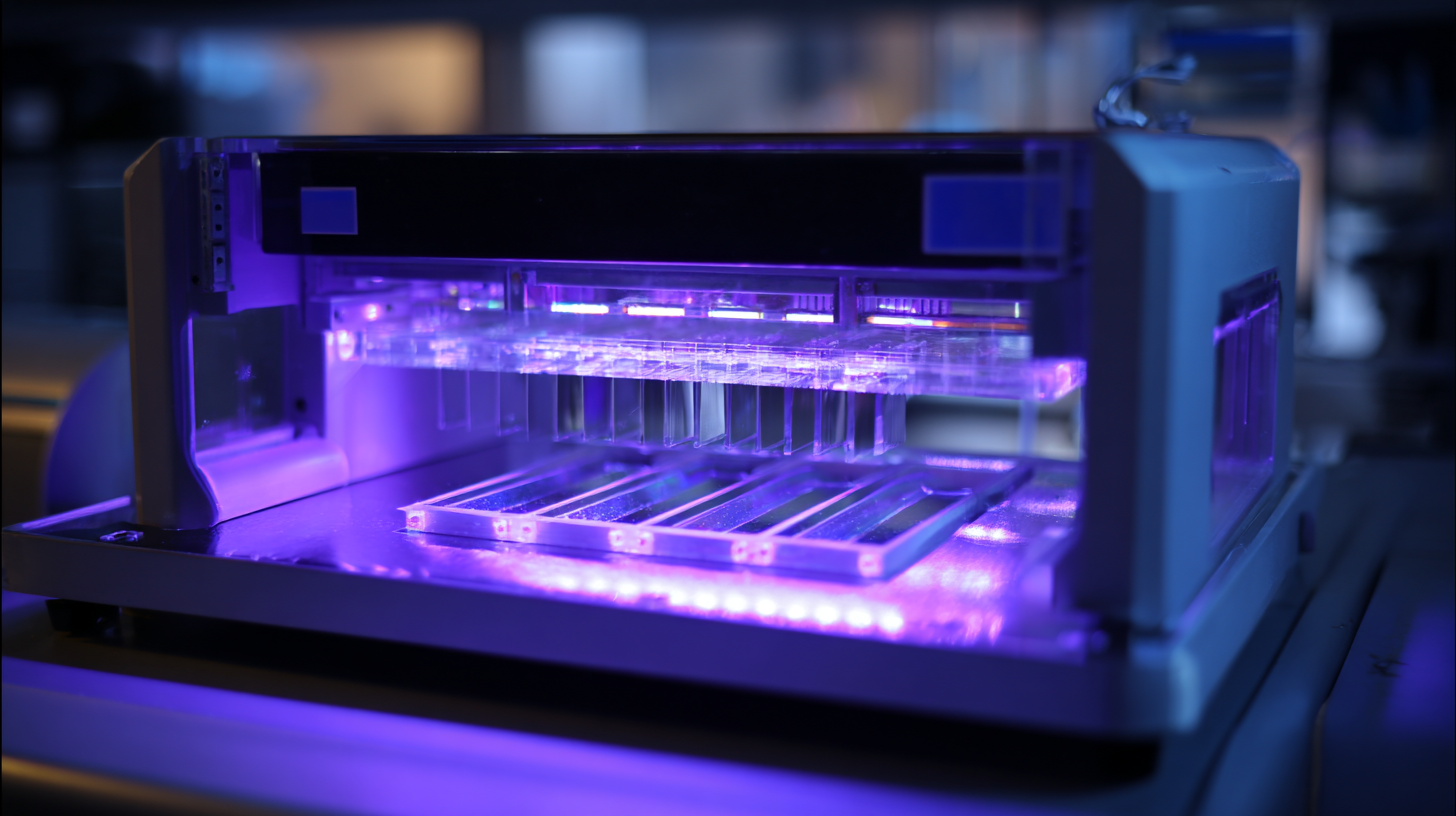

The adhesives and sealants market is witnessing remarkable growth, projected to reach USD 91.23 billion by 2030. This surge underscores the evolving needs of various industries for reliable and efficient bonding solutions. Among the innovations driving this growth are UV glue curing lamps, which significantly enhance adhesive bonding techniques. These lamps offer a rapid curing process, reducing production times and improving overall efficiency.

Complementing this trend, the UV LED market is also expanding, with a keen focus on advanced technologies and applications. A range of UV curing technologies, including UV-A, UV-B, and UV-C, are shaping the landscape, while power outputs vary from below 1W to above 10W, catering to diverse industry requirements. This is further reflected in the photoinitiator market, projected to grow from USD 146.09 million in 2024 to USD 253.6 million by 2030. These statistics illustrate the substantial efficiency gains being realized through UV glue curing solutions, promising a transformative impact on adhesive bonding processes across multiple sectors.

The adhesive bonding industry is experiencing a transformative shift with the integration of UV curing technology. As traditional methods become less efficient, UV glue curing lamps offer an innovative approach that significantly reduces bond setting times while ensuring strong, durable connections. This technology harnesses ultraviolet light to cure adhesives almost instantaneously, which opens new avenues for productivity across various applications, from automotive to electronics.

Tips for utilizing UV curing technology effectively include ensuring proper alignment of the adhesive application and the curing lamp for optimal exposure. It's crucial to select adhesives specifically designed for UV curing to maximize bonding strength and minimize any potential weaknesses. Additionally, operators should maintain a clean workspace to prevent contamination of adhesive surfaces, ensuring that the bond remains unaffected during the curing process.

The future of adhesive bonding is bright with advancements in UV curing. As innovations continue, we can expect to see more customizable solutions that cater to specific industry needs, increasing efficiency and sustainability in production processes. Embracing these trends will not only enhance bonding techniques but also drive the development of eco-friendlier adhesive products, paving the way for a more sustainable future in manufacturing.