Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

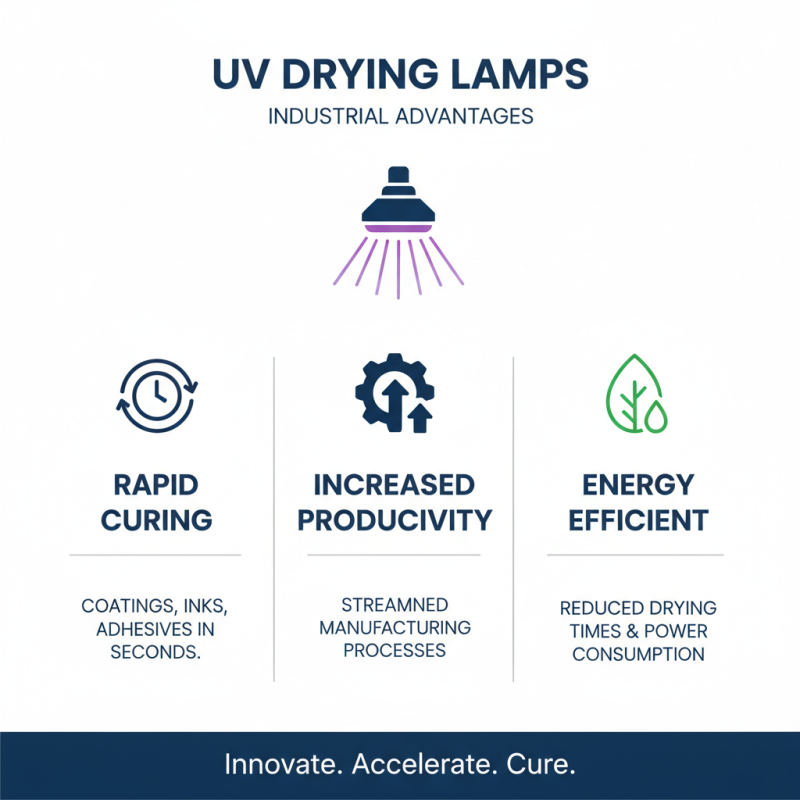

The UV drying lamp has revolutionized the curing process in various industries. From printing to coatings, its efficiency is unmatched. This technology uses ultraviolet light to quickly dry inks and adhesives. Many businesses have adopted UV drying lamps for their speed and effectiveness.

However, not all UV drying lamps are created equal. Some models may not provide uniform drying, leading to uneven results. It's essential to choose the right lamp based on specific needs. Many users sometimes overlook maintenance and calibration, affecting performance.

Despite these challenges, the benefits are significant. The UV drying lamp reduces curing time, saves energy, and improves productivity. Understanding its uses can help businesses maximize their potential. Exploring how to select and use these lamps effectively is vital for success in many applications.

UV drying lamps are essential tools in various industries. They use ultraviolet light to cure or dry inks, coatings, and adhesives quickly. These lamps emit specific wavelengths that initiate a photochemical reaction. As a result, materials solidify rapidly, enhancing production efficiency.

One significant benefit of UV drying lamps is their speed. According to the Industry Reports, companies can save up to 50% in drying time, leading to faster turnaround. Additionally, UV lamps operate at lower temperatures compared to conventional drying methods. This feature reduces the risk of heat-damaged substrates and allows for a broader range of materials.

Tip: Ensure proper safety measures when using UV lamps. Prolonged exposure can harm skin and eyes. Always wear protective gear to mitigate risks.

Moreover, UV drying technology is environmentally friendly. It does not require solvents, minimizing harmful emissions. This aspect contributes to sustainable practices in manufacturing and printing. However, transitioning from traditional drying methods to UV systems can pose challenges. Companies may face initial costs and require training to adapt.

Tip: Consider starting with a small-scale UV system to gauge its effectiveness before a full transition. This method helps in understanding the practical benefits without overwhelming investment.

UV drying lamps are essential in many industries, offering numerous benefits. They provide quick curing times, which enhance productivity. A UV lamp can cure coatings, inks, and adhesives in seconds. This speed is valuable for manufacturers looking to streamline processes.

The versatility of UV drying lamps is impressive. They are widely used in graphic printing, automotive, and electronics. For instance, in printing, eager customers expect fast turnaround times. UV lamps meet this demand efficiently. They also help reduce drying defects, making the finished product more reliable.

Tips: Regular maintenance of UV lamps can improve performance. Check for bulb wear and replace them timely. Additionally, careful monitoring of the curing process is vital to prevent under-cured products. Always ensure proper ventilation in workspaces using UV drying lamps.

UV drying technology has become prominent in various industries. Its effectiveness is particularly noticeable in printing, coatings, and adhesives. Recent studies indicate that companies using UV systems can reduce drying time by up to 80%. This transformation helps businesses boost productivity and minimize waste.

In the printing industry, UV drying lamps play a significant role. They offer immediate curing, making vibrant colors and sharp details possible. Reports highlight that UV-cured inks significantly enhance resistance to scratches and fading. Such improvements appeal to consumers who expect durability. However, switching to UV technology requires careful consideration of equipment costs and technical knowledge.

The wood finishing sector also benefits from UV drying systems. These lamps provide a sturdy finish and quick turnaround. A study showed that 90% of wood finishers experienced a reduction in curing-related delays. Yet, adjustments in product formulation may be necessary. This change poses challenges for some manufacturers. Balancing efficiency with quality remains an ongoing discussion in the industry.

UV drying lamps utilize ultraviolet light to hasten drying processes. They are widely used in industries such as printing, coatings, and adhesives. These lamps rapidly cure inks and resins, leading to efficient production cycles. According to industry reports, UV curing can be up to three times faster than traditional drying methods.

Understanding how UV drying lamps work is crucial. The UV light initiates a photochemical reaction. This reaction causes the inks or coatings to harden almost instantly. An effective setup requires selecting the right wavelength and intensity. Both play vital roles in maximizing effectiveness. However, opting for the wrong specifications can lead to incomplete curing and possible defects.

Tips: Regular maintenance of UV lamps is essential for optimal performance. Ensure proper calibration to avoid inconsistencies in curing. Consider the material being cured. Different materials absorb UV light differently, impacting the drying time. It’s important to test and adjust settings accordingly. Achieving the right balance can prevent issues like uneven finishes. Always keep safety in mind when operating UV lamps.

| Benefit/Use | Description | Applications | Industry |

|---|---|---|---|

| Quick Drying | UV lamps cure coatings and inks rapidly, reducing production time. | Printing, Coating | Manufacturing |

| Energy Efficiency | Lower energy consumption compared to conventional drying methods. | Various Surface Treatments | Industrial |

| Curing of Adhesives | Provides strong bonds with quick curing times. | Assembly, Packaging | Manufacturing, Packaging |

| No VOC Emissions | Environmentally friendly as UV curing does not emit volatile organic compounds. | Environmentally Conscious Products | Green Technology |

| Versatile Applications | Applicable to a variety of materials including plastics, wood, and metal. | Furniture, Electronics | Multi-Industry |

Choosing the right UV drying lamp is crucial for effective curing. Different applications require different wavelengths and intensities. For instance, a lamp used in nail salons must emit specific UV light to cure gels properly. In contrast, lamps used in packaging need to ensure fast drying for inks and coatings.

When selecting a UV drying lamp, consider your workspace and materials. A compact lamp may work for small setups, while larger operations might need a powerful, stationary unit. Also, reflect on the cooling system. UV lamps often generate heat that can affect your work. Some models come with fans, which might be necessary for longer curing times.

It's important to think about longevity. UV lamps have a lifespan that can vary significantly. Regularly checking the output and replacing the bulbs will save time and improve quality. Missing this step could lead to inconsistent curing and wasted materials, prompting frustration down the line. Understanding these factors ensures a better fit for your specific needs.

This chart illustrates the various benefits of UV drying lamps as of 2026, highlighting their effectiveness in fast drying, energy efficiency, environmental friendliness, durability, and versatility for different applications.